Rod and wire heating furnace achieving flexible matching direct hot loading of casting machine and rolling mill

A heating furnace and walking heating furnace technology, applied in the field of industrial furnaces, can solve problems such as production cost savings and mismatching production and maintenance systems, achieve stable operation, increase hot delivery and hot charging rate and furnace entry temperature, and increase production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

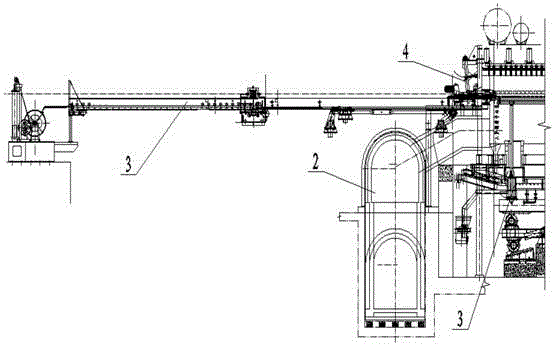

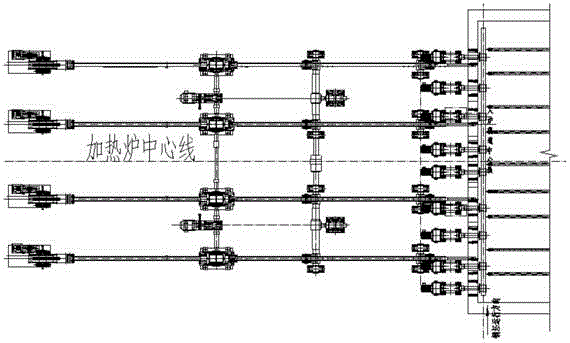

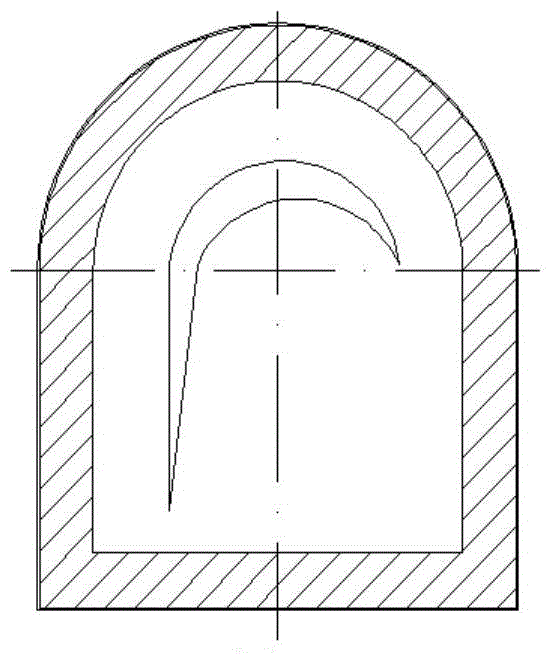

[0035] Figure 1-Figure 5 It is a specific embodiment of the present invention. Below with regard to the patent of the present invention is described as follows in conjunction with accompanying drawing.

[0036] The invention patent includes the cantilever roller side-in and side-out walking type heating furnace body and auxiliary equipment 1, the smoke exhaust pipe and the smoke exhaust flue under the charging end 2, the flexible matching charging machine 3, and the hanging type steel pusher into the furnace 4.

[0037] 1. Cantilever roller side-in and side-out walking heating furnace body and auxiliary equipment

[0038] Cantilever roller side-in and side-out walking heating furnace body and auxiliary equipment 1 includes furnace bottom stepping machinery, furnace bottom water seal tank, furnace bottom water beam, furnace bottom steel structure, cantilever roller table at the loading and unloading end, furnace body Steel structure, furnace masonry, heating furnace combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com