Underwater installation method for main thruster

An installation method and thruster technology, applied in transportation and packaging, ship parts, ships, etc., can solve the problems of disrupting the production rhythm of shipbuilding enterprises, increasing shipbuilding construction costs, and prolonging the construction period, so as to avoid the production rhythm and reduce the cost of ships. Maintenance cost, effect of reducing docking cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

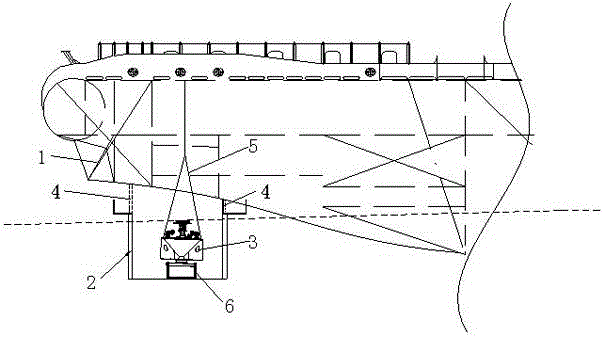

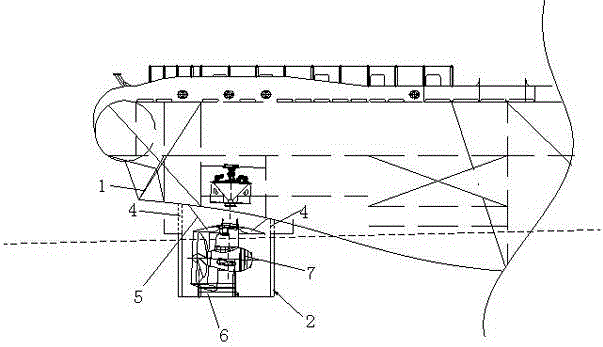

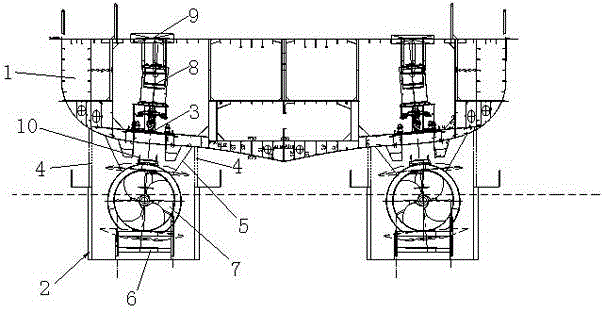

[0035] Such as Figure 1-3 Shown, a kind of main thruster underwater installation method comprises the following steps:

[0036] 1) Adjust the floating state of the carrier ship according to the installation space requirements of the main propeller, and reserve a certain installation space at the installation position of the main propeller;

[0037] 2) Design and manufacture an auxiliary buoyancy tank according to the external dimensions and weight of the main thruster underwater part of the main thruster to be installed;

[0038] 3) Use the lifting device to hoist the main thrust gearbox to the installation position, and make a fixed connection. The installation of the main thrust gearbox specifically includes the following steps;

[0039] a) hoisting the main propulsion gearbox into the auxiliary pontoon, and moving the auxiliary pontoon to the installation space below the carrier ship;

[0040] b) Adjust the floating state of the auxiliary pontoon, after aligning the main...

Embodiment 2

[0053] The underwater installation method of the main thruster comprises the following steps:

[0054] 1) Adjust the floating state of the carrier ship according to the installation space requirements of the main propeller, and reserve a certain installation space at the installation position of the main propeller;

[0055] 2) Design and manufacture an auxiliary buoyancy tank according to the external dimensions and weight of the main thruster underwater part of the main thruster to be installed;

[0056] 3) According to the installation position of the main propulsion gearbox, an installation hole is opened on the deck, and the main propulsion gearbox is hoisted from the installation hole into the cabin of the carrier ship by a lifting device, and the fixed connection of the main propulsion gearbox is completed;

[0057] 4) hoisting the underwater part of the main propulsion into the auxiliary buoyant tank, and moving the auxiliary buoyant tank to the installation space below...

Embodiment 3

[0063] An underwater disassembly method of a main propeller, according to the reverse process of embodiment 1, with the help of the auxiliary buoyancy tank, the main propeller underwater part and the main propeller gearbox can be disassembled, and the carrier ship is in a floating state The disassembly of the main propeller is realized without entering the dock, which saves docking costs and is conducive to improving construction efficiency and reducing costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com