Automatic drainage system for cable tunnel

A technology for cable tunnels and automatic drainage, applied in drainage, non-electric variable control, control/regulation systems, etc., can solve the problems of cable tunnels and tunnel facilities hazards, and achieve the effect of ensuring safety and realizing automatic control of drainage systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

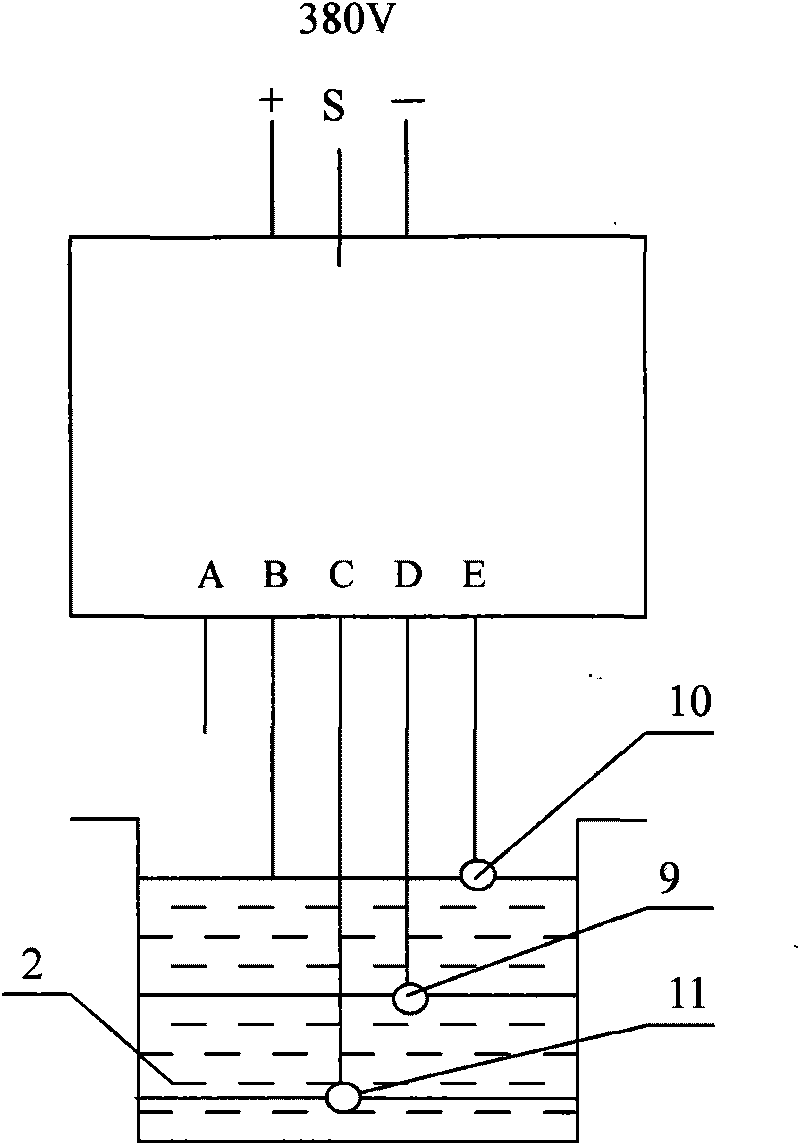

[0010] 1. dig a collecting well (2) at the lowest part of the cable tunnel (1), install two submersible pumps in the collecting well: submersible pump A (3), submersible pump B (4), connect the cable tunnel (1) and The main drainage pipe (3) is dug through, and the connecting pipe (8) is made with a cement pipe. Then connect the water outlet of the submersible pump to the main drainage pipe.

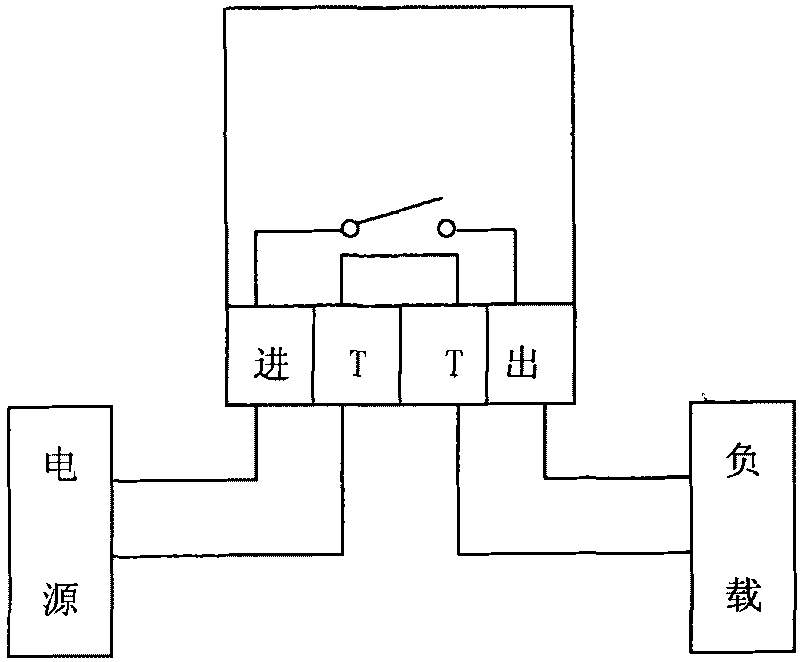

[0011] 2. E- is the high water level control point of the water collection well. When the water level rises to point E, the water contacts the high water level probe (9), and the water level controller automatically turns on the submersible pump B (7). D- is the low water level control point of the sump well, if the water level drops below the D point water level, the low water level probe (8) is out of contact with the water, and the water level controller automatically closes the submersible pump B (7). When the water level rose to point D, the low water level probe (8) was in contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com