Cutting device of high-precision optical fiber length and cutting method thereof

A technology of optical fiber length and cutting device, applied in the field of optical fiber, can solve problems such as low cutting precision, and achieve the effect of high cutting precision, easy platform construction, and high-precision cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

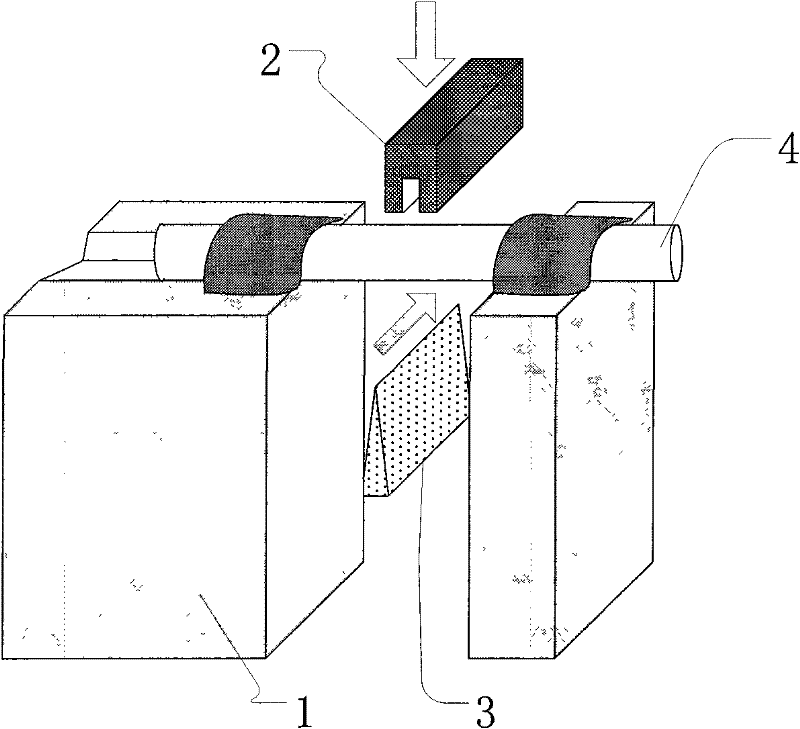

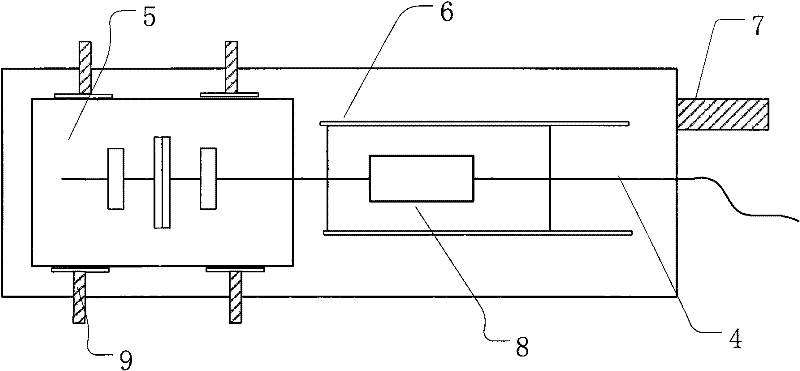

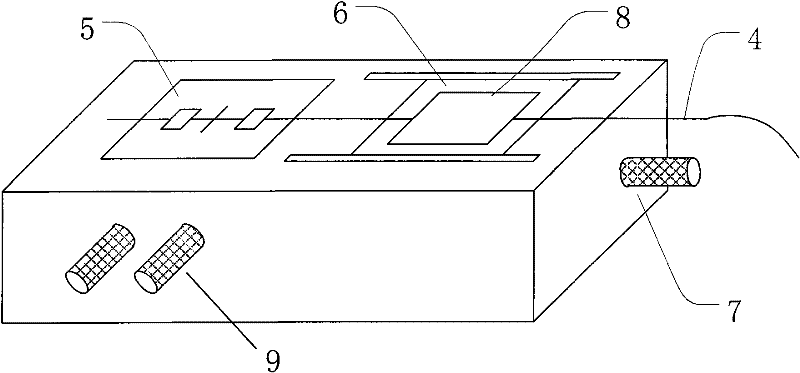

[0021] Such as figure 2 and image 3 As shown, in the present invention, a high-precision displacement platform is designed in conjunction with the existing optical fiber cutter. The optical fiber cutter 5 is composed of a cutting blade 3 and a crushing arm 2 that cooperates with it, and the optical fiber 4 to be cut is fixed on the optical fiber holder 1. . Its basic composition principle is that the optical fiber cutter 5 is fastened on the left side of the high-precision optical fiber displacement platform through the fixing fixture 9, and the optical fiber propulsion table 6 is set on the right side of the high-precision optical fiber displacement platform through the precision propulsion reading mechanism. Under the action of the reading mechanism, the upper fixed optical fiber 4 to be cut can be driven to move precisely in the direction of the optical fiber cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com