Control system of intelligent automatic wire cutting machine

A technology of control system and servo control system, applied in the field of control system of intelligent automatic thread trimmer, can solve problems such as insufficient accuracy, inability to deal with complex and changeable, labor-intensive, etc., to improve quality and efficiency, enrich interface pre- The effect of retaining and solving manual problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

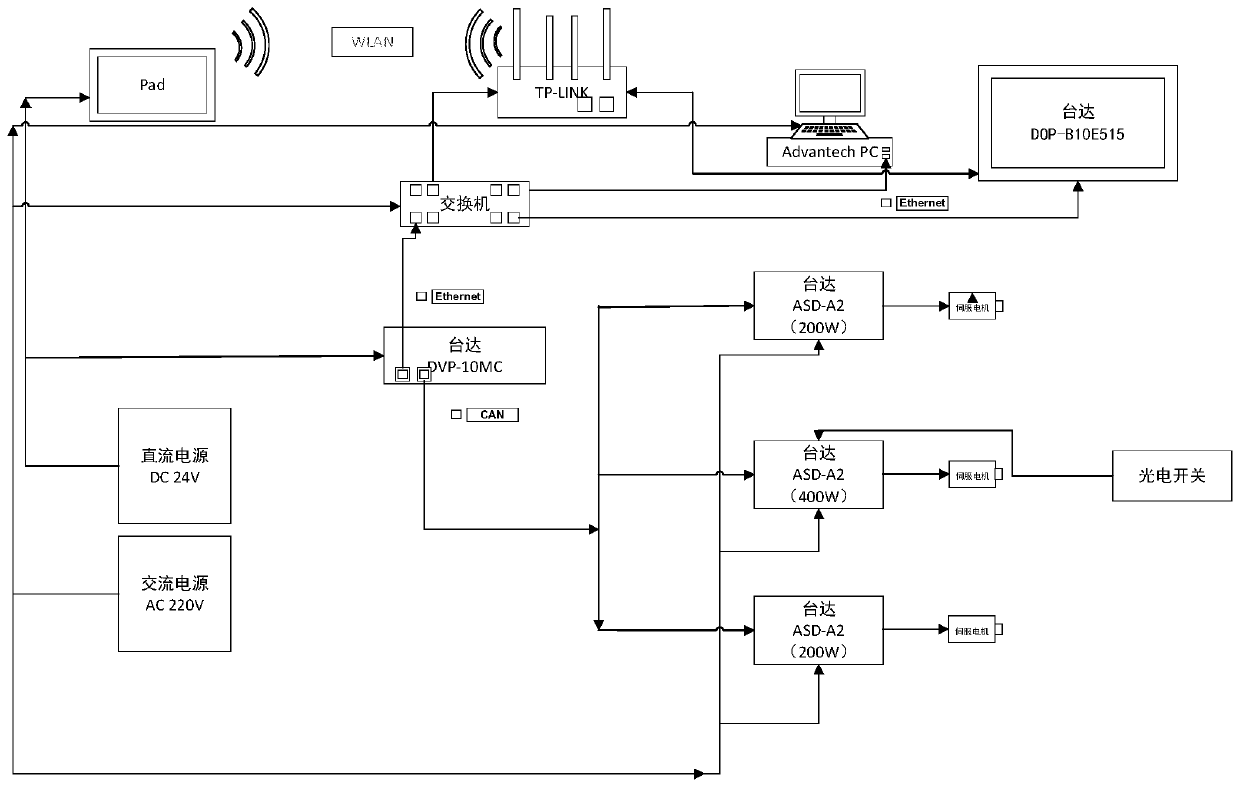

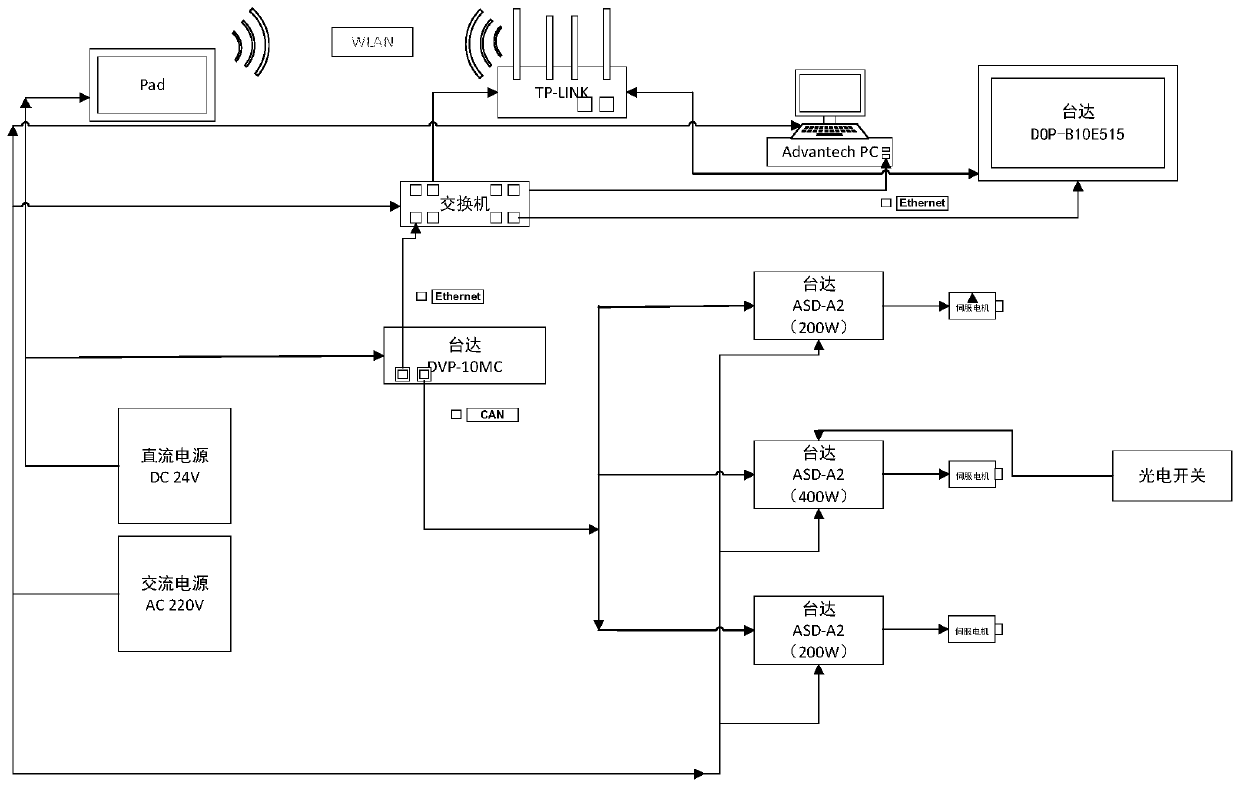

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a control system of an intelligent automatic thread trimmer, including Delta DVP-10MC motion controller, two 200W Delta ASD-A2 servo control systems, one 400W Delta ASD-A2 servo control system, Delta DOP-B10E515 man-machine interface, photoelectric switch, computer, switch, DC 24V power supply and AC 220V power supply; the Delta DVP-10MC motion controller communicates with two 200W Delta ASD-A2 servo control systems through the CAN bus It is connected with a 400W Delta ASD-A2 servo control system. At the same time, each servo drive system also communicates through the CAN bus. The Delta DVP-10MC motion controller is used as the control core, and three Delta ASD-A2 servos are used. The control system drives the mechanical structure to cooperate with each other, and first complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com