Equipment installation structure

A technology for equipment installation and construction, applied to substations/switchgear boards/panels/desks, etc., can solve the problem of time-consuming installation and operation of circuit breakers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

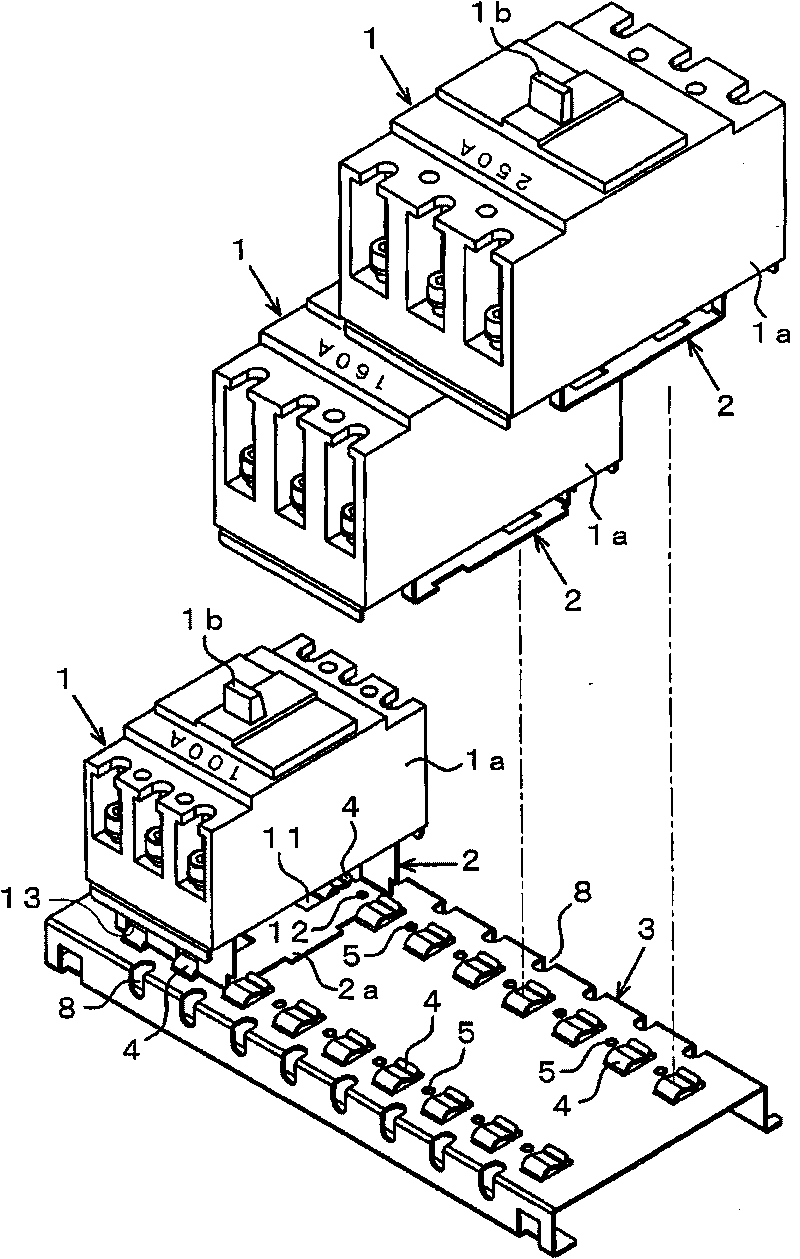

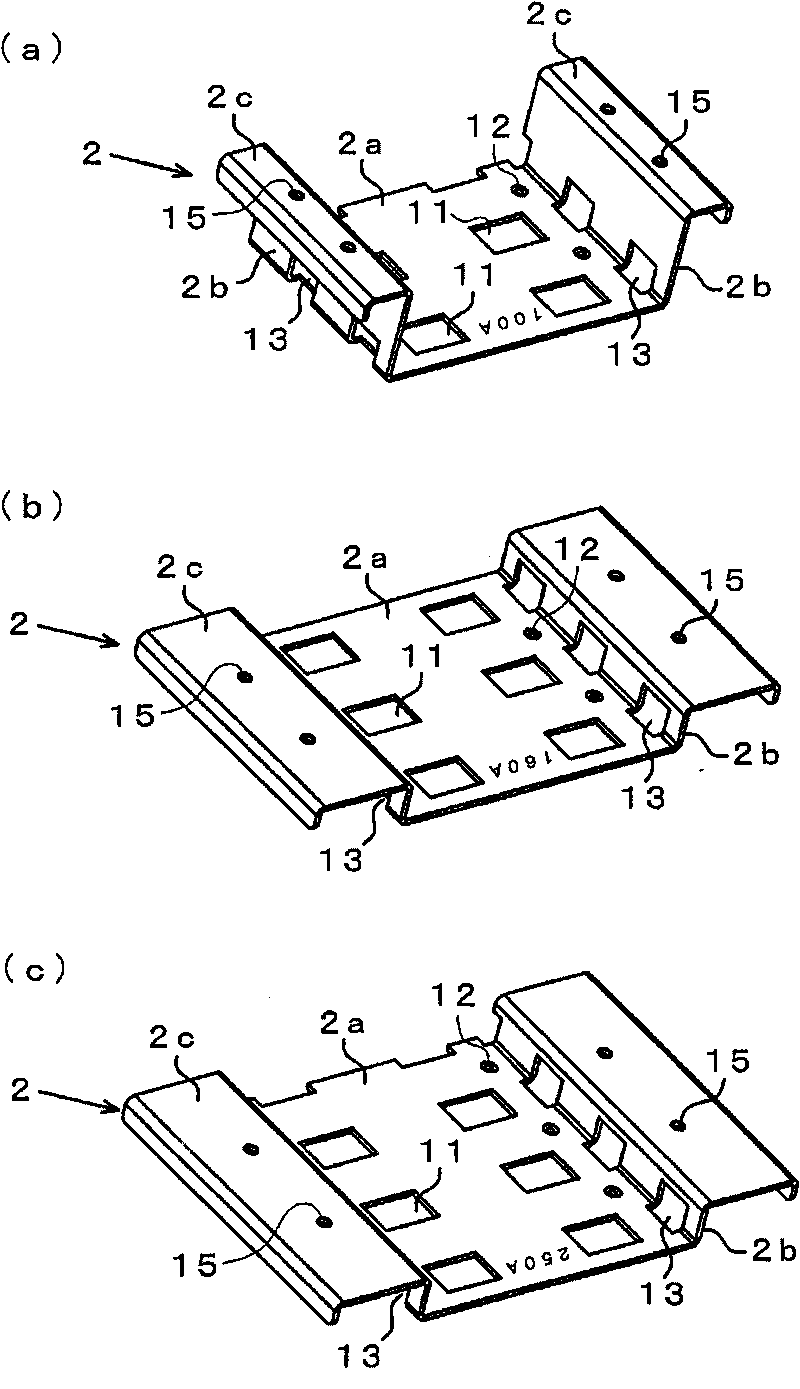

[0037] Such as figure 1 As shown, in the circuit breaker installation structure of this embodiment, three circuit breakers 1 are installed on a common bottom plate 3 via respective installation platforms 2 . Each circuit breaker 1 has a frame 1a having external dimensions corresponding to the load capacity (100A, 160A, 250A), and a handle 1b is provided on the upper surface of the frame 1a. Each mounting table 2 is formed with substantially the same planar area as the bottom area of the frame 1a, and the bottom plate 3 is formed in a size capable of mounting three mounting tables 2 thereon.

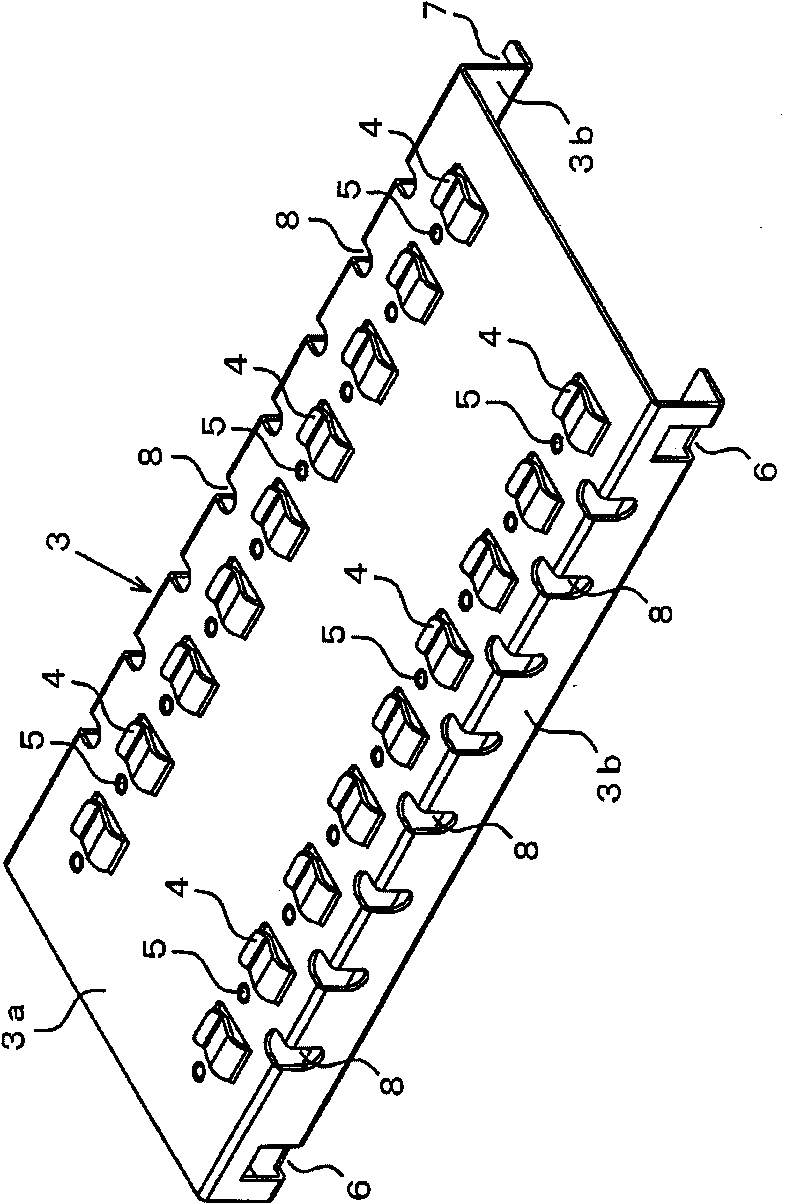

[0038] Such as figure 2 As shown, the bottom plate 3 is formed by bending a metal plate, and is provided with a flat surface portion 3a on which the mounting base 2 is placed and a pair of leg portions 3b mounted on a switchboard (not shown). On the planar portion 3a, a plurality of clamping pieces 4 and the same number of stoppers 5 are formed in two rows at equal intervals along t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap