Non-contact type transmission device with high coaxiality

A non-contact, transmission technology, applied in electromechanical transmissions, electromechanical devices, electric components, etc., can solve the problems of difficult control, unstable transmission torque, low transmission coaxial precision, etc., to achieve cost saving and simple installation. Reliable and good fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

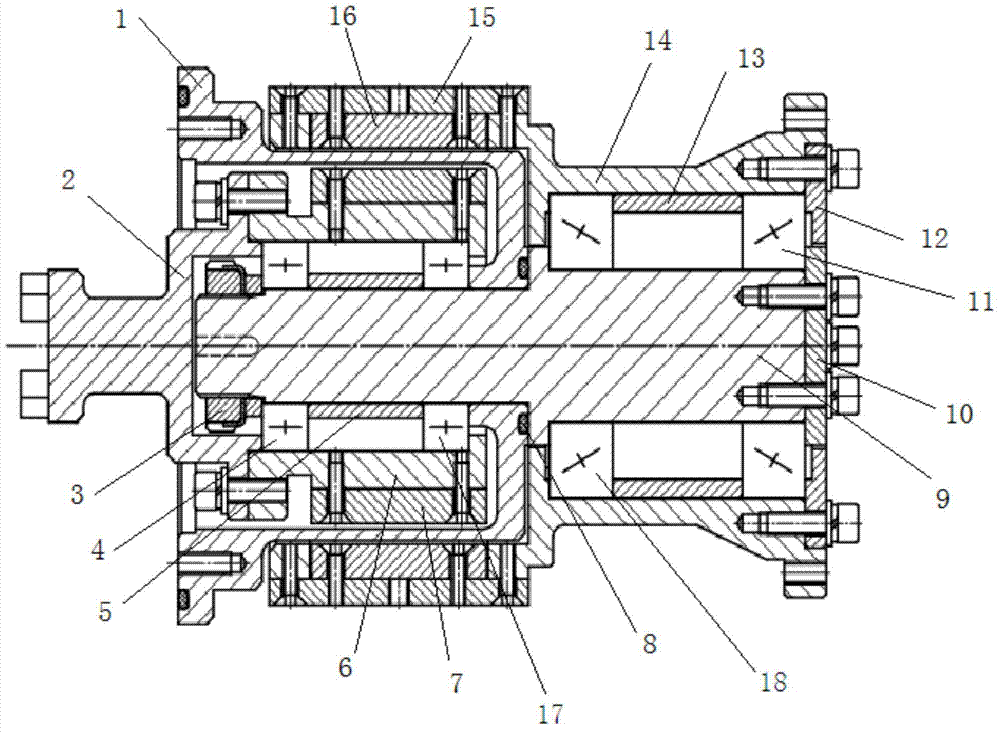

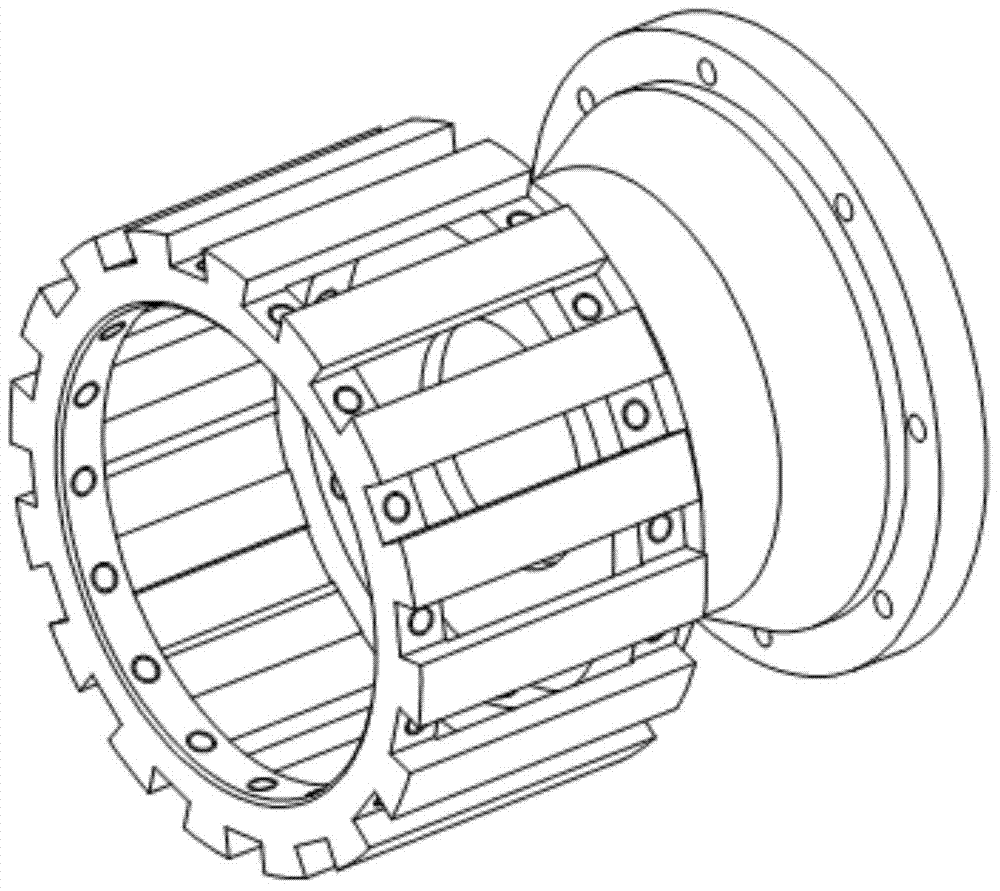

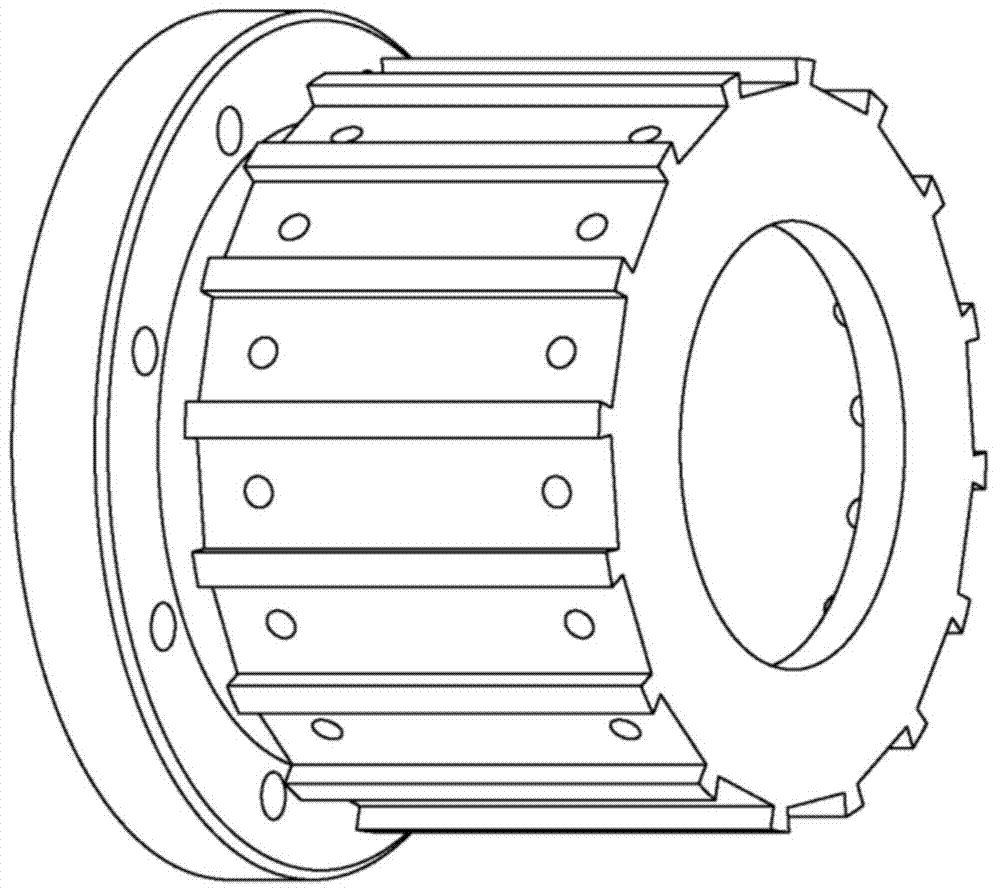

[0021] Such as Figure 1 to Figure 4 As shown, the technical solution for the specific implementation of the present invention is: a non-contact transmission device with high coaxiality, which is characterized in that it includes a spacer sleeve 1, an inner transmission shaft 2, a small bearing b4, a small shaft sleeve 5, and an inner rotor 6. Permanent magnet A7, reference shaft 9, baffle plate 10, large bearing b11, bearing cover 12, large shaft sleeve 13, outer rotor 14, mounting plate 15, permanent magnet B16, small bearing a17 and large bearing a18;

[0022] A shoulder is provided on the reference shaft 9;

[0023] One end of the spacer 1 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com