Sealing covering cap for opening of outer hanging point of plane

A hanging point and aircraft technology, applied in the field of aircraft structure design, can solve problems such as restricting aircraft performance, aircraft stealth performance and aerodynamic performance, etc., and achieve simple and reliable installation, small weight and external dimensions of the mechanism, and rapid modification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] This embodiment is a sealing flap for the opening of a certain type of aircraft's hardpoint.

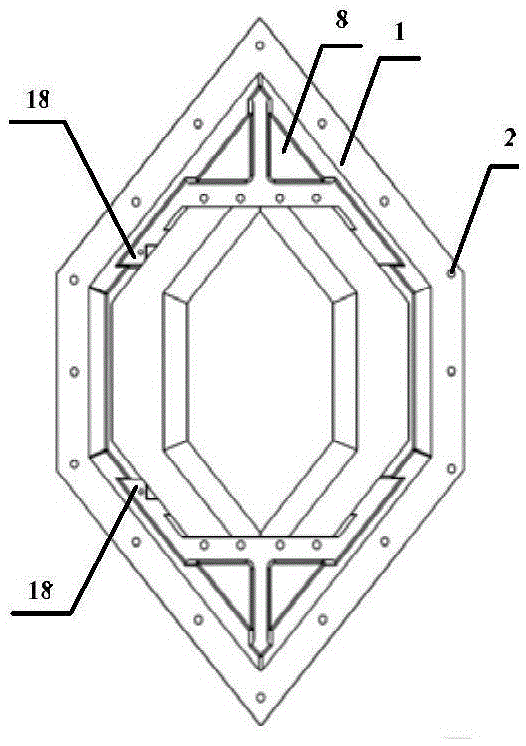

[0047] The coordinate system of the sealing flap is defined as figure 1 Shown: the y direction is the flying direction of the aircraft, the x direction is the span direction, and the z direction is above the aircraft.

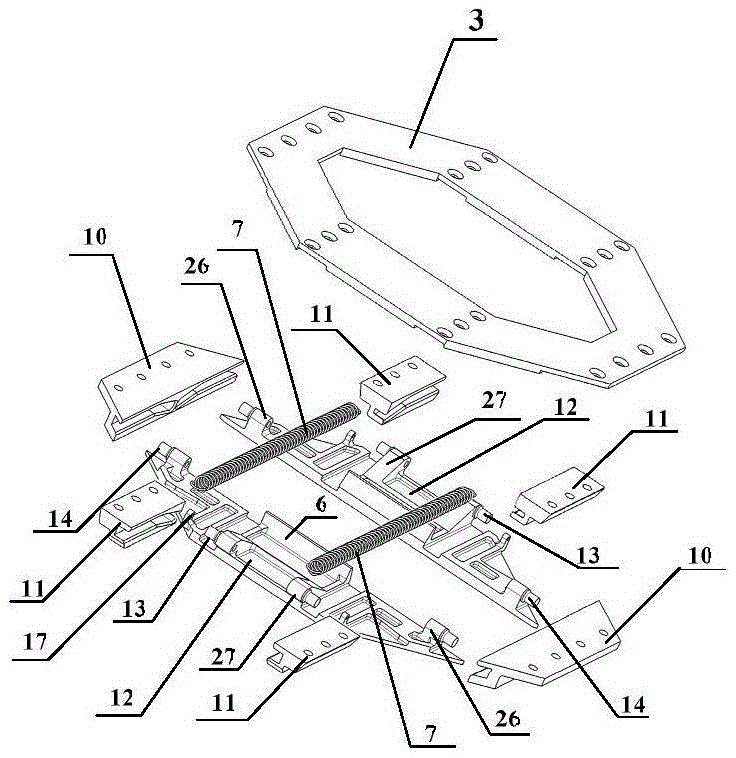

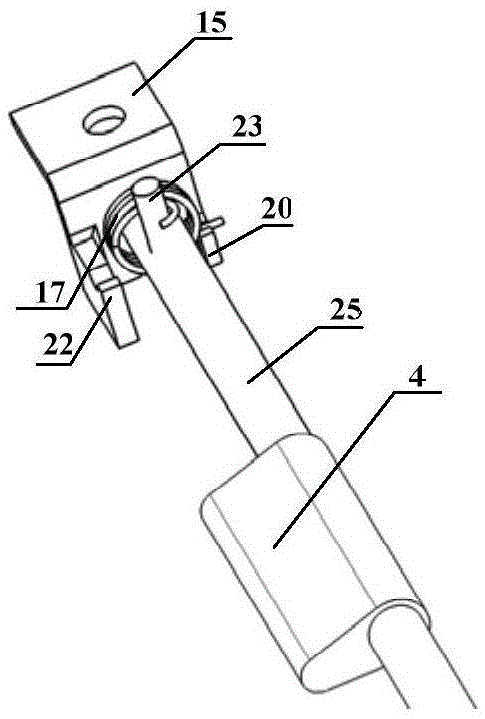

[0048] This embodiment includes a housing 1, 2 sealing plates 12, 2 sealing tension springs 7, 1 sealing plate cover plate 3, 2 pairs of inner guide rails 11, 2 outer guide rails 10, 2 sealing plate reset wrenches 6. 4 inner rail rollers 13, 4 outer rail rollers 14, 2 symmetrically arranged locking device pins 25, 4 locking device hooks 4, 4 locking device limit pins 23, 2 locking device hoops 15. Two locking device torsion springs 16. Each of the components is located in the shell 1, such as figure 2 shown.

[0049] Consists of 1 sealing plate 12, 1 sealing plate cover 3, 2 pairs of inner guide rails 11, 2 outer guide rails 10, 14 cover plate fixing bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com