Low-noise rotating shaft

A low-noise, rotating shaft technology, applied in the direction of magnetic circuit rotating parts, casing/cover/support, electric components, etc., to achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

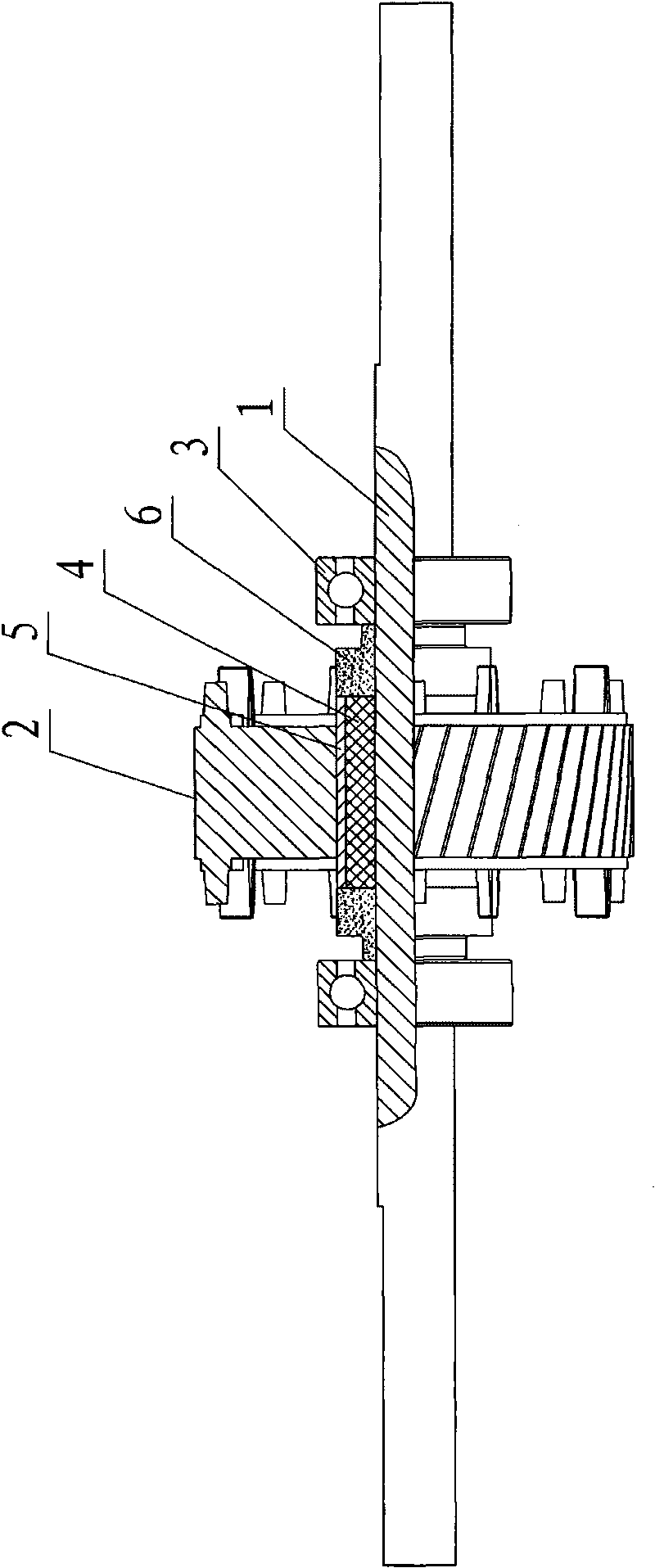

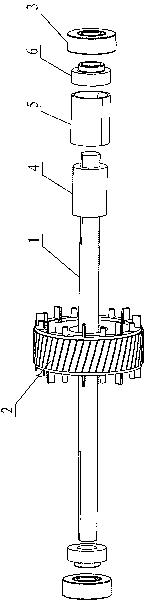

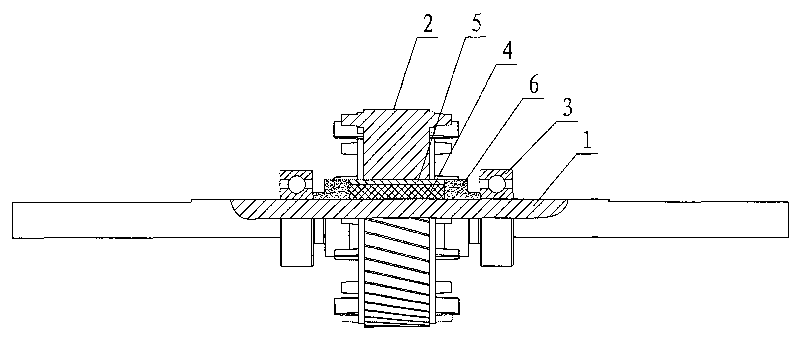

[0015] Such as figure 1 figure 2 The low-noise rotating shaft shown has a shaft 1, a cast aluminum rotor 2 sleeved on the shaft 1, and two bearings 3. The rotor 2 has a shaft hole, and the shaft 1 is equipped with a vibration damping ring at the matching position of the shaft hole of the rotor 2. 4.

[0016] The outer ring of the vibration-damping ring 4 is wrapped with fixed pieces 5, and the fixed pieces 5 are three separately dispersed fixed pieces, which are evenly distributed on the outer ring of the vibration-damping ring 4 . The damping ring 4 is a rubber damping ring, and the fixed piece 5 is a metal fixed piece. The fixed piece 5 is press-fitted in the shaft hole of the rotor 2 together with the shaft 1 on which the damping ring 4 is installed.

[0017] An anti-slip sleeve 6 is respectively installed on both sides of the fixed piece 5, and two bearings 3 are respectively press-fitted on the outside of each anti-slip sleeve 6.

[0018] The vibration damping ring 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com