A reactor noise evaluation and noise optimization method and device

A reactor and noise technology, which is applied in the field of reactor noise evaluation and optimization, can solve problems such as increased production costs, poor heat dissipation of reactors, and increased product weight, and achieve weight reduction, simple and effective evaluation methods, and avoidance of noise reduction devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

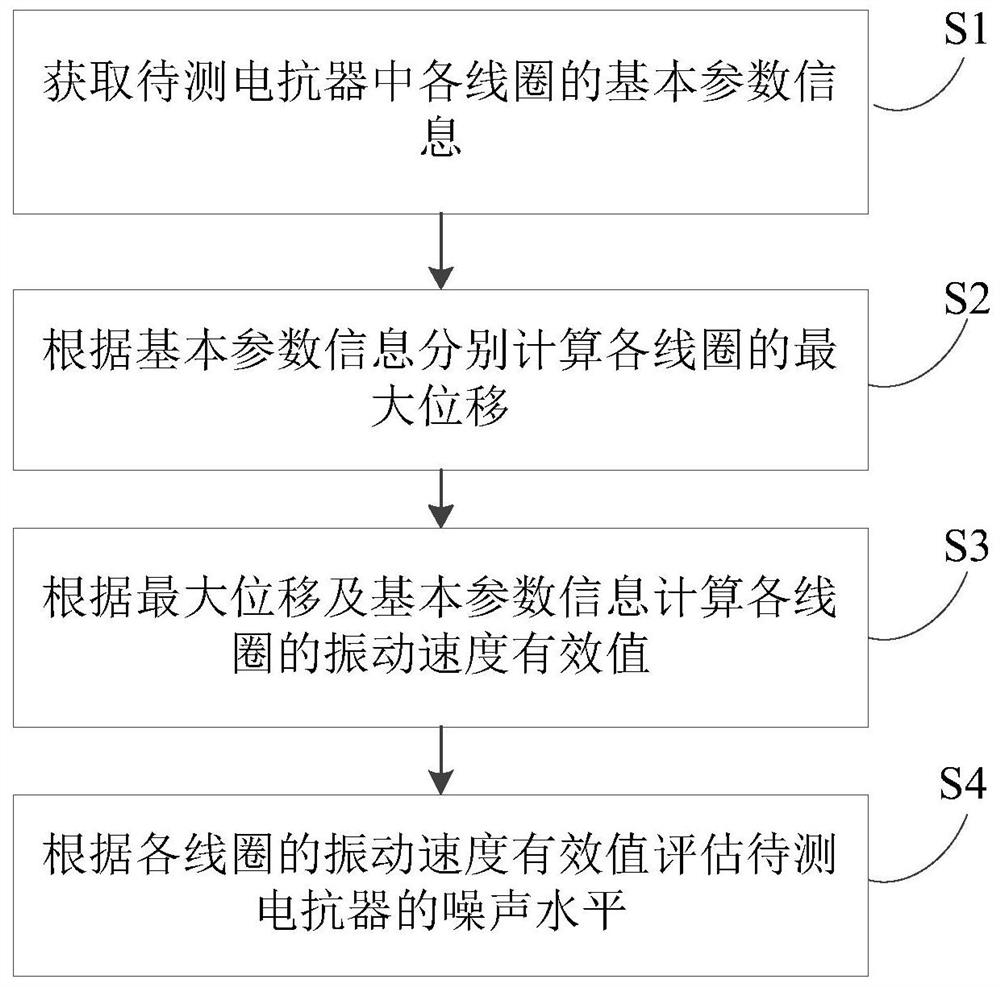

[0036] An embodiment of the present invention provides a reactor noise evaluation method, such as figure 1 As shown, the reactor noise evaluation method includes:

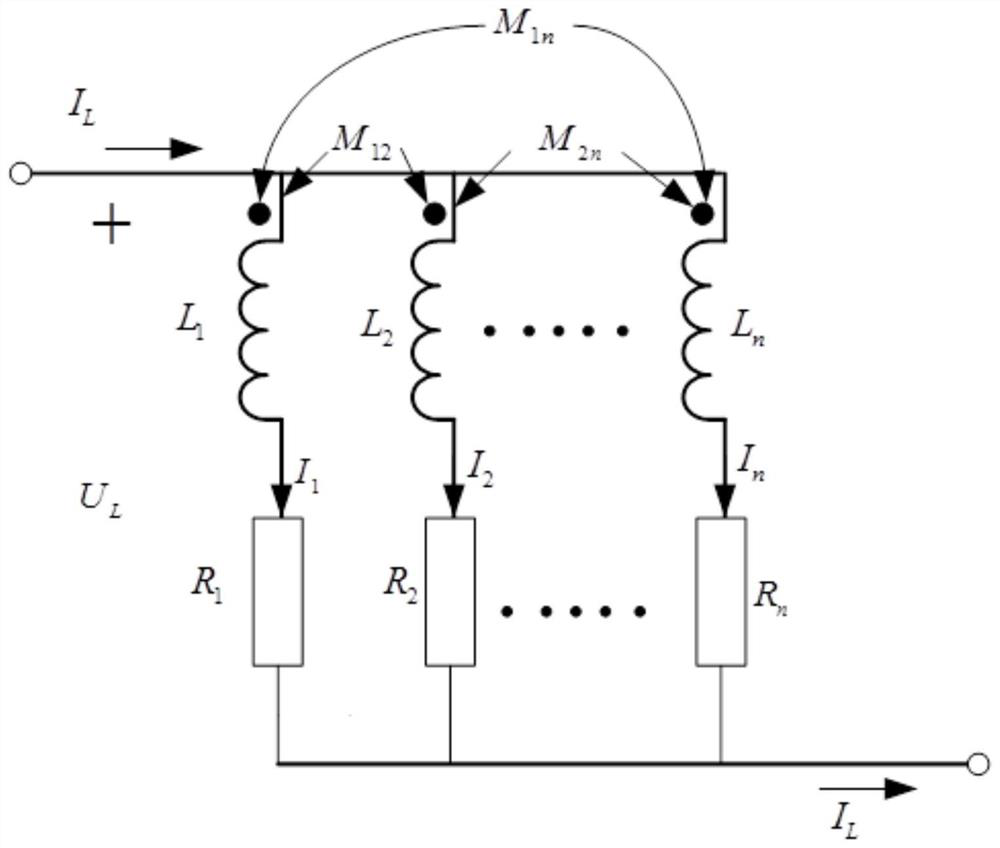

[0037] Step S1: Obtain basic parameter information of each coil in the reactor to be tested. Specifically, the basic parameter information includes: the effective value of the harmonic current of each coil at different preset frequencies, the magnetic induction intensity, the number of turns of the coil, the length of the coil, the cross-sectional area of the wire, and the like.

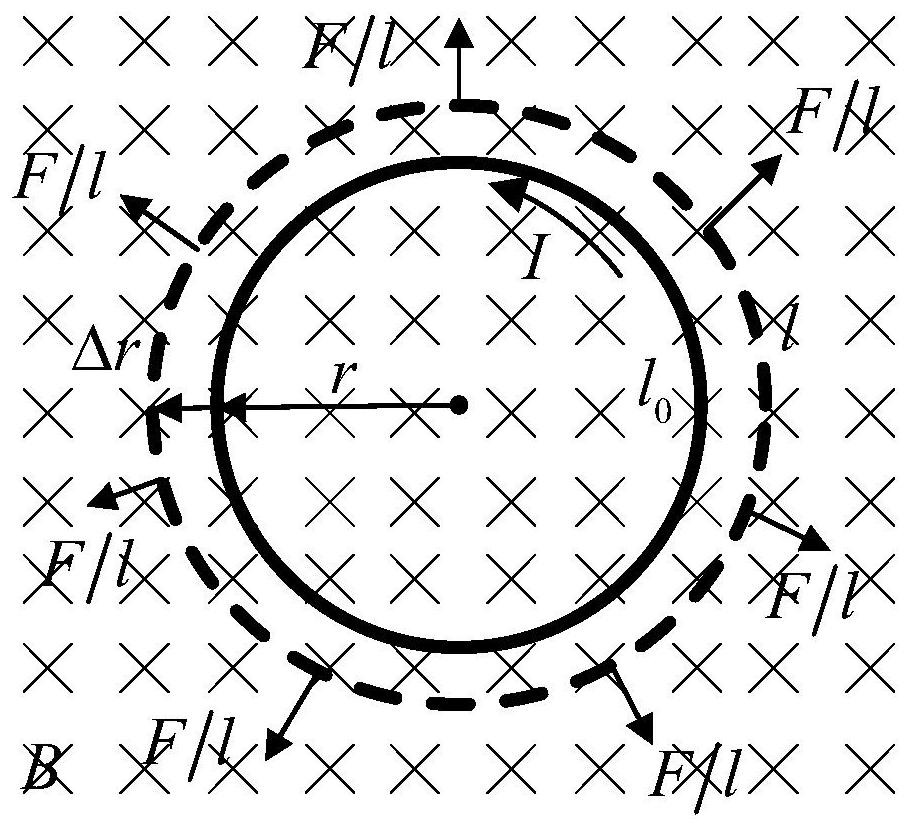

[0038] Step S2: Calculate the maximum displacement of each coil respectively according to the basic parameter information. Specifically, the mass points on each coil will be displaced under the influence of electromagnetic force, and the maximum displacement reflects the maximum amplitude of coil vibration.

[0039] Step S3: Calculate the effective value of the vibration velocity of each coil according to the maximum displacement and ...

Embodiment 2

[0076] An embodiment of the present invention provides a reactor noise optimization method, such as Figure 5 As shown, the reactor noise optimization method includes:

[0077] Step S5: Evaluate the noise level of the reactor to be optimized by using the reactor noise evaluation method in Embodiment 1. Each coil of the reactor to be optimized has parameters such as the number of turns of the coil and the cross-sectional area of the wire.

[0078] Step S6: judging whether the noise level meets the preset noise requirement.

[0079] Step S7: When the noise level satisfies the preset noise requirement, determine the design parameters of the reactor to be optimized according to the current parameters of the number of turns of the coil and the cross-sectional area of the wire.

[0080] By executing the above steps S5 to S7, the reactor noise optimization method provided by the embodiment of the present invention realizes the optimal design of reactor parameters, reduces the no...

Embodiment 3

[0091] An embodiment of the present invention provides a reactor noise evaluation device, such as Figure 7 As shown, the reactor noise evaluation device includes:

[0092] The parameter information obtaining module 1 is used to obtain the basic parameter information of each coil in the reactor to be tested. For details, refer to the relevant description of step S1 in Embodiment 1.

[0093] The maximum displacement calculation module 2 is used to calculate the maximum displacement of each coil according to the basic parameter information. For details, refer to the relevant description of step S2 in Embodiment 1.

[0094] The vibration speed effective value calculation module 3 is used to calculate the vibration speed effective value of each coil according to the maximum displacement and basic parameter information. For details, refer to the relevant description of step S3 in Embodiment 1.

[0095] The noise level evaluation module 4 is used for evaluating the noise level o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com