Joint punching mechanical hand

A technology of manipulators and gripping hands, applied in the field of manipulators, can solve problems such as hindering the operation of operators, inconvenient operation, safety accidents, etc., and achieve the effects of improving convenience, convenient operation and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

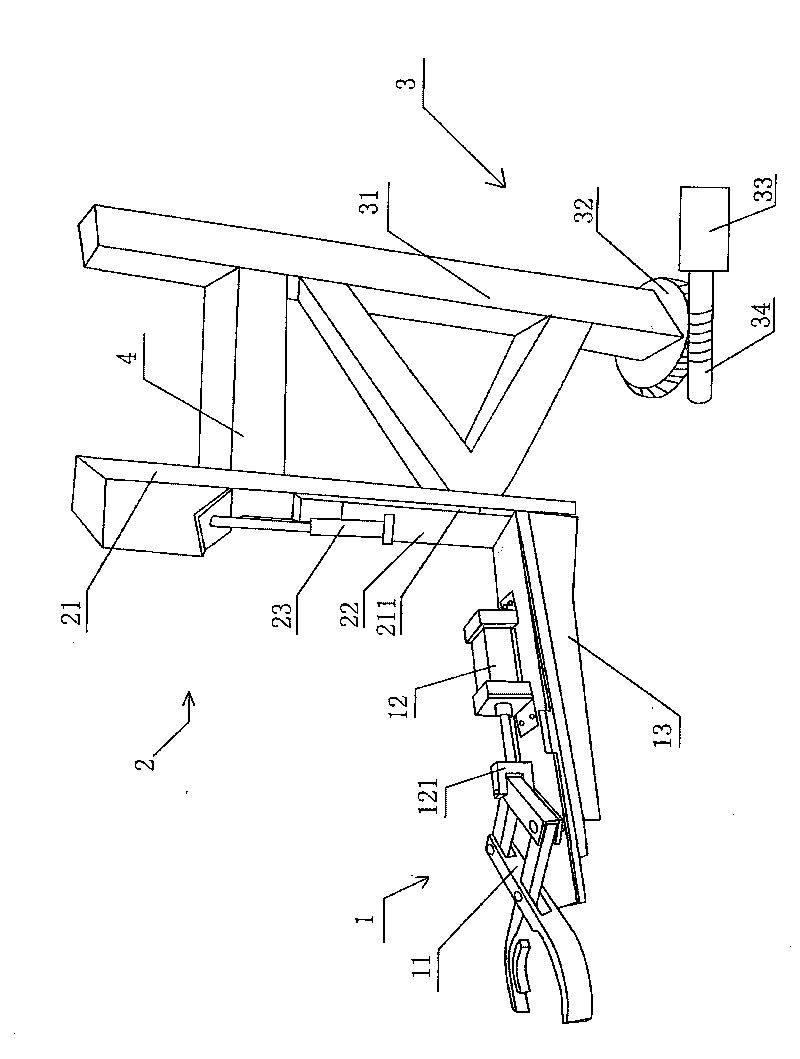

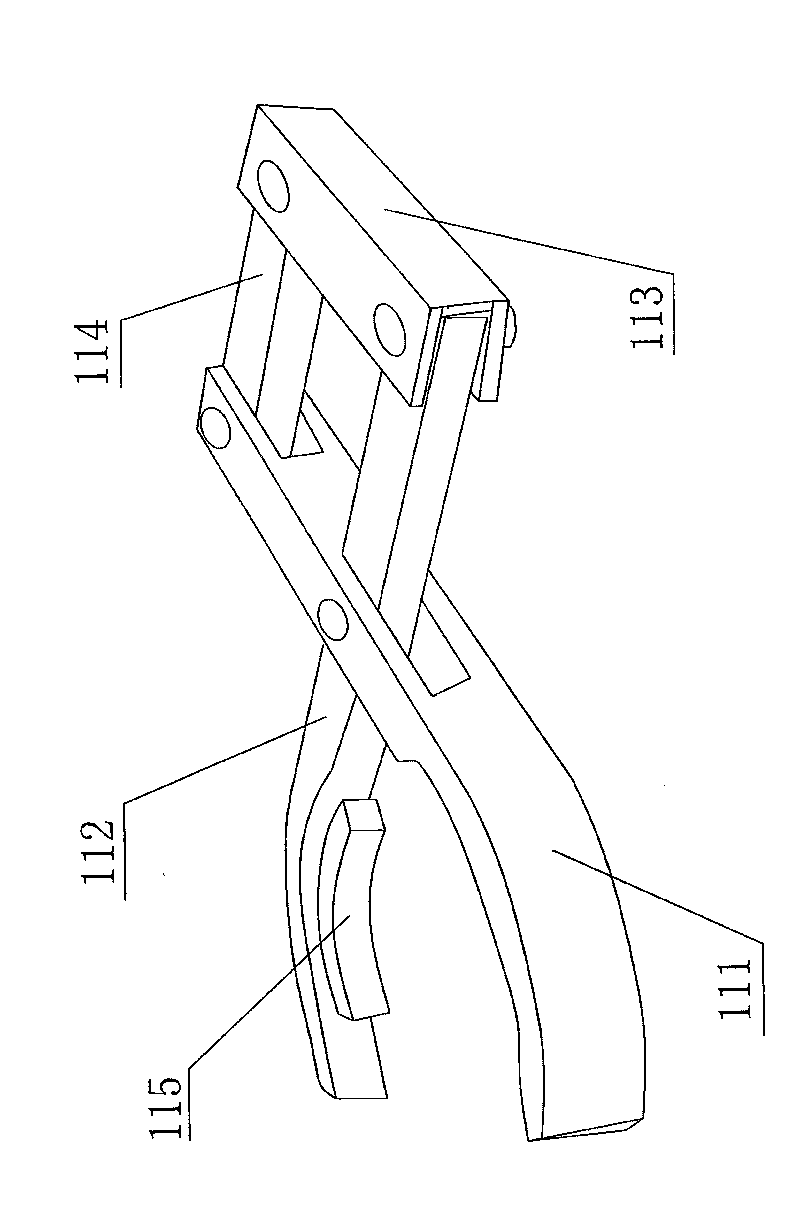

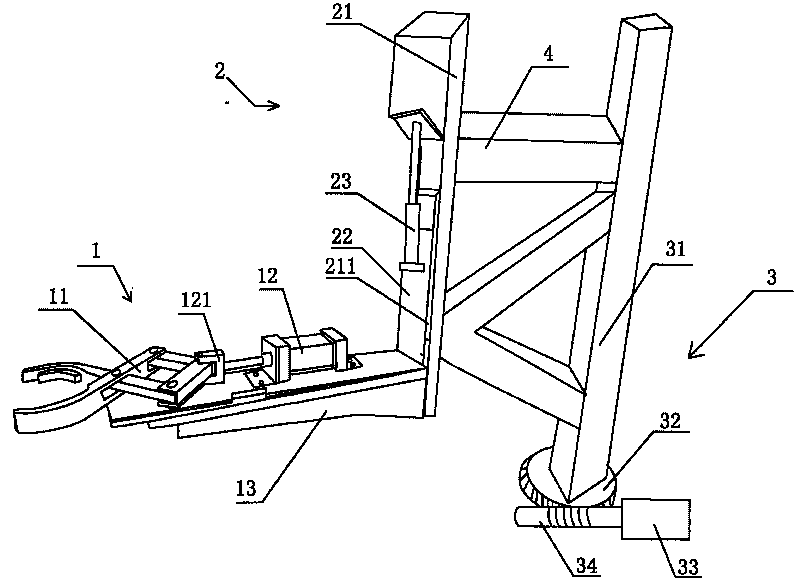

[0021] see figure 1 , the present invention relates to a joint piercing manipulator, which includes a gripping mechanism 1, a lifting mechanism 2, a rotating mechanism 3 and a connecting beam 4, and the gripping mechanism 1 includes a gripping hand 11, a traverse cylinder 12 and a clamping support 13; see figure 2 , the gripper 11 includes a left gripper 111, a right gripper 112, a first connecting rod 113 and a second connecting rod 114, the front ends of the left gripper 111 and the right gripper 112 are arc-shaped structures, and Left and right can form a ring structure, the middle of the left clip 111 is provided with a through hole, the right clip 112 passes through the through hole and is hinged with one end of the first connecting rod 113, and the left clip 111 is in the The through hole is hinged with the middle part of the right clip 112, the other end of the first connecting rod 113 is hinged with one end of the second connecting rod 114, the other end of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com