Conveyer

A technology for conveying devices and conveying parts, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve problems such as defects and container cover damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

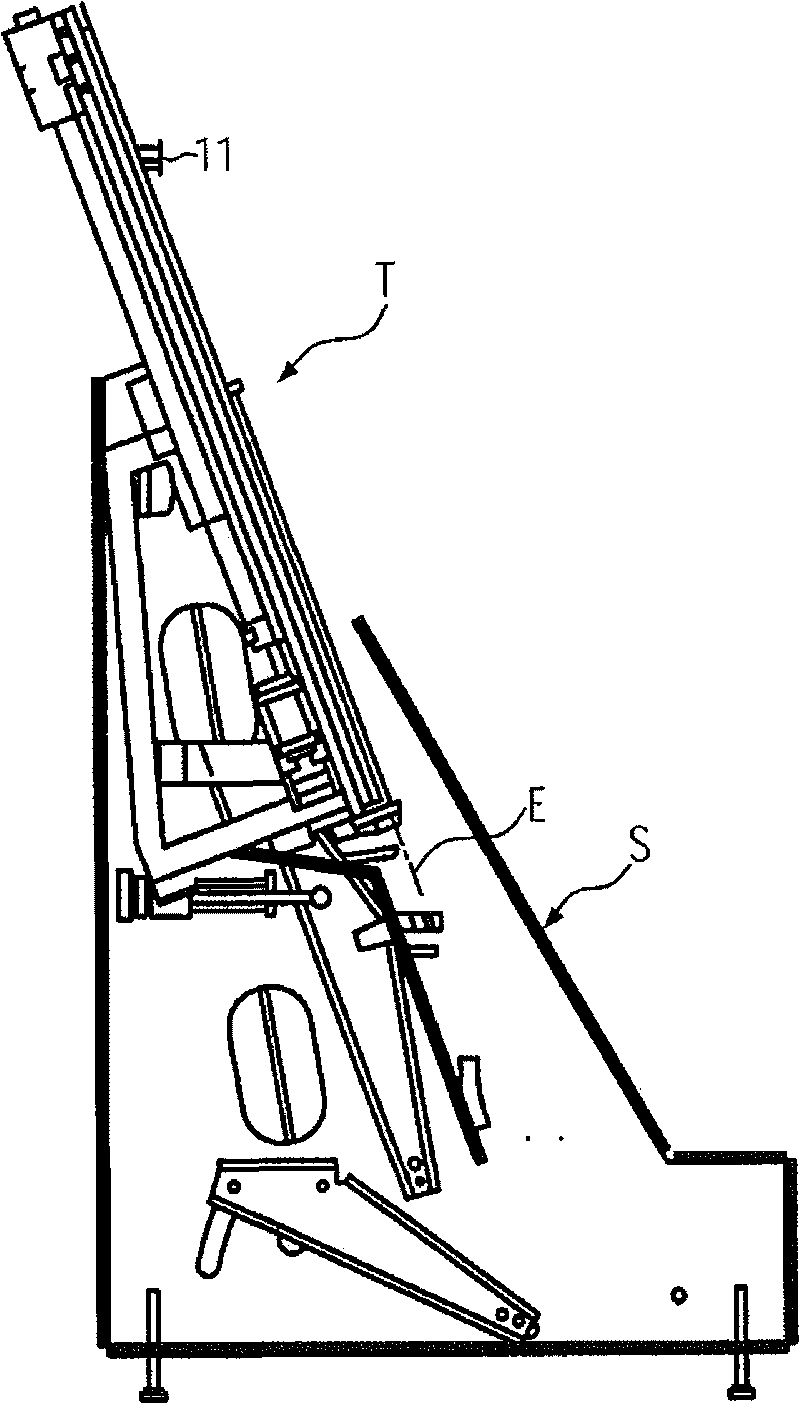

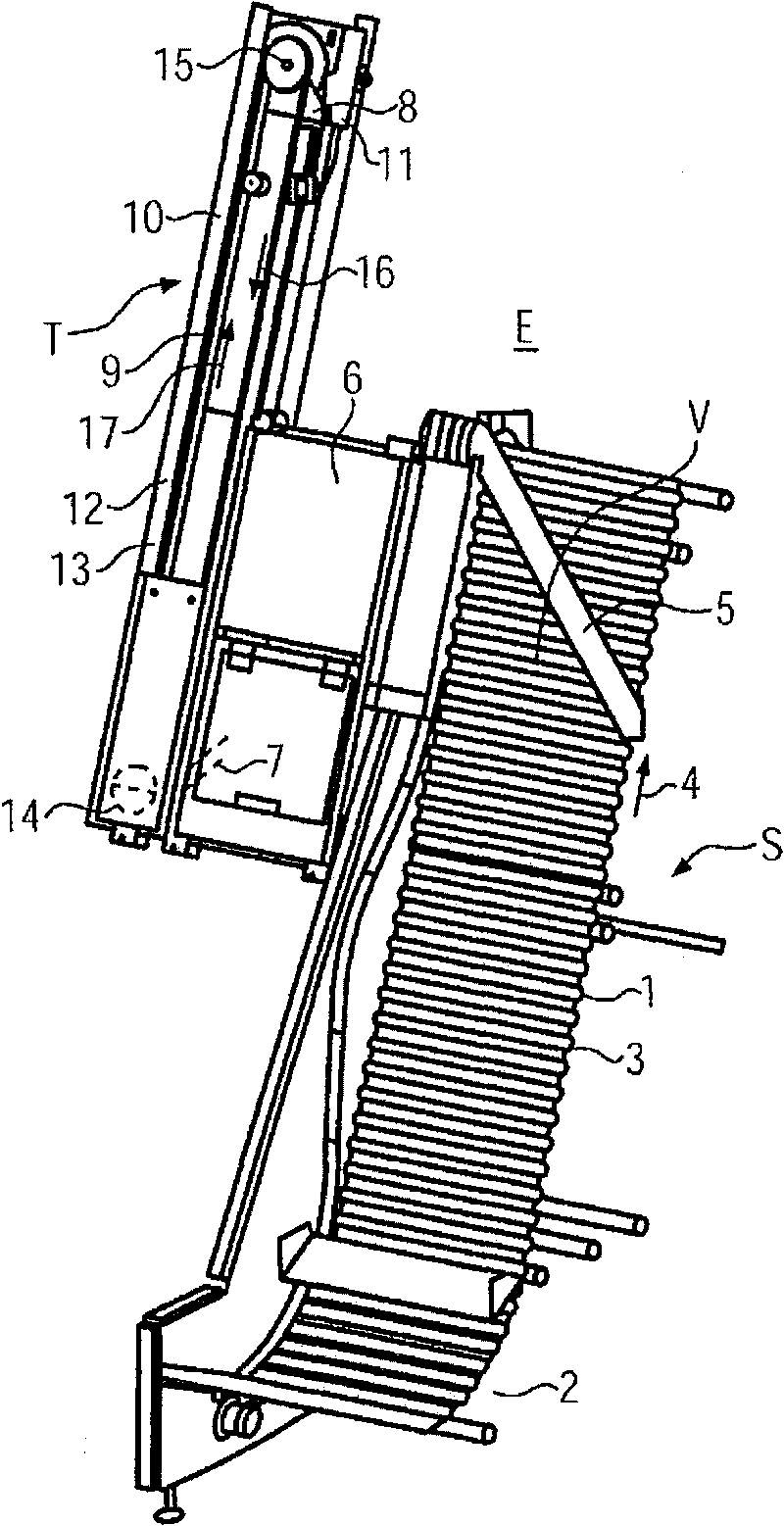

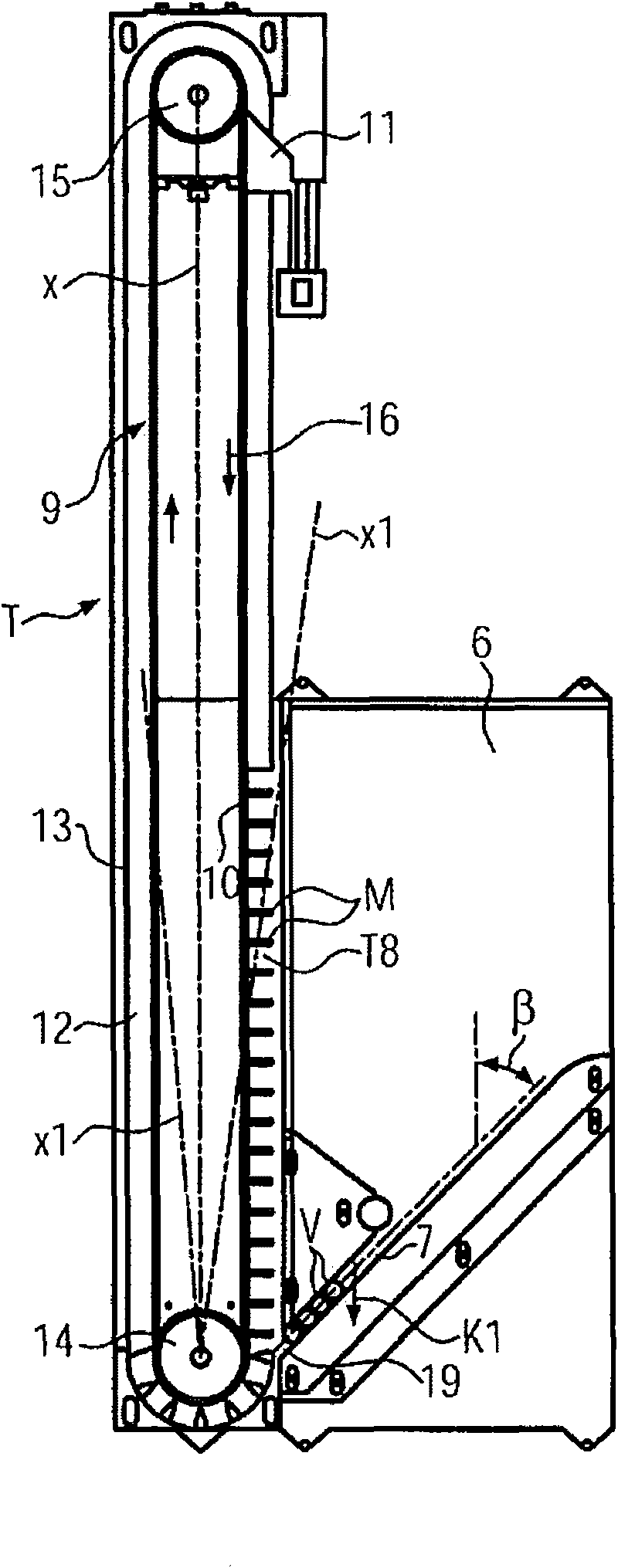

[0033] In container handling machines used in the beverage filling industry or in container closure systems, it is often necessary to sort container closures in piece goods and supplied in any orientation into a single orientation and to sort the sorted containers in the processing sequence of the corresponding machine The cover is conveyed upwards to the designated high position. In this regard, it is known to use the figure 1 and figure 2 The sorting unit S and the conveying device T are shown, wherein the sorting unit S and the conveying device T cooperate with each other functionally.

[0034] The sorting unit S comprises, for example, a webbing 1 with strip-like entrainment members 3 extending transversely, and enables the removal of container closures V initially provided in random orientations from the reservoir 2 below. Due to the rising movement of the webbing 1 of increasing steepness, each container lid V will be correctly oriented under the action of gravity with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com