Anti-lightning protection gap for traction power supply system of electrified railway

A traction power supply system, electrified railway technology, applied in circuits, electrical components, overvoltage arresters using spark gaps, etc., can solve problems such as no lightning protection measures, and achieve good anti-corrosion effect, simple installation, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

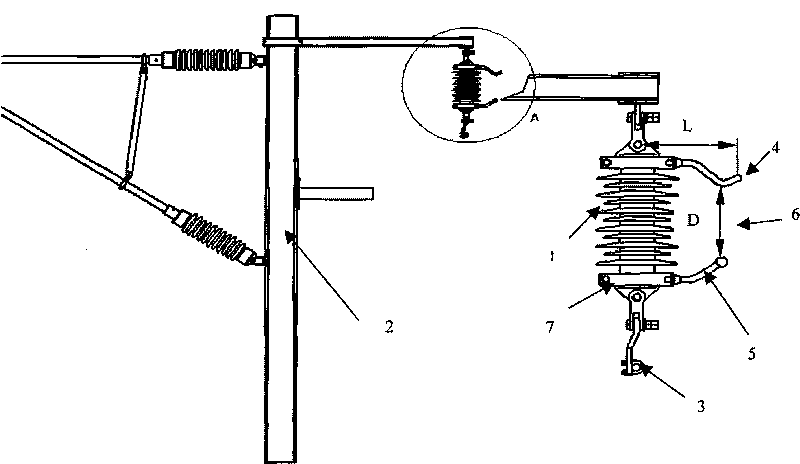

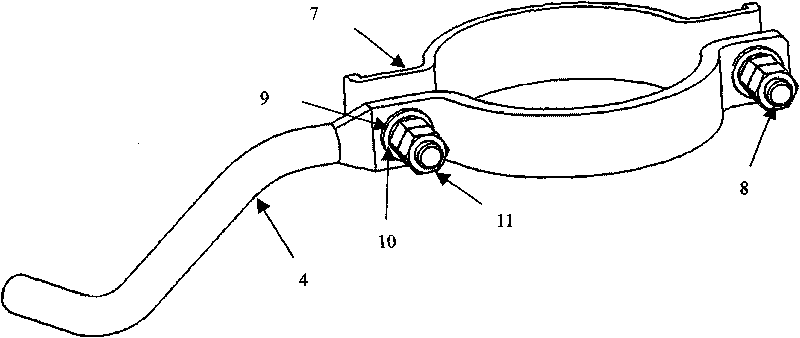

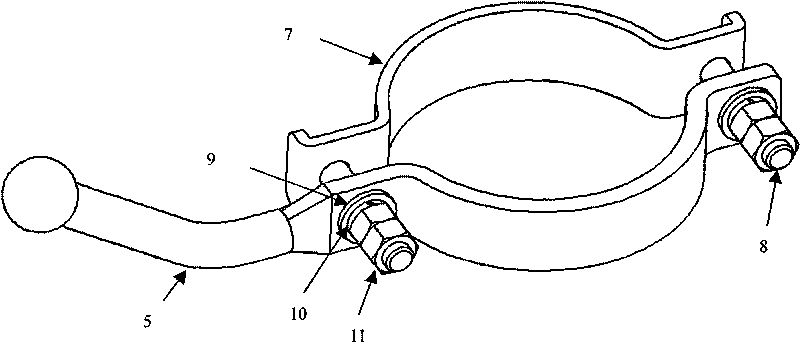

[0023] figure 1 It shows one of the embodiments of the present invention, a schematic diagram of the overall installation structure when a suspended rod-shaped porcelain insulator is used, mainly including a suspended rod-shaped porcelain insulator 1, a column 2, an F line 3, a claw-shaped electrode 4, and a ball head The rod-shaped electrode 5, the well-grounded metal column 2 is connected with the upper fitting of the suspended rod-shaped porcelain insulator 1 through the connecting fitting, and the lower fitting of the suspended rod-shaped porcelain insulator 1 is connected with the F line of the railway power supply system through the connecting fitting. The middle of the rod-shaped porcelain insulator 1 is an insulating part; the upper fitting of the suspended rod-shaped porcelain insulator 1 is provided with a horn-shaped electrode 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com