Pneumatic tire

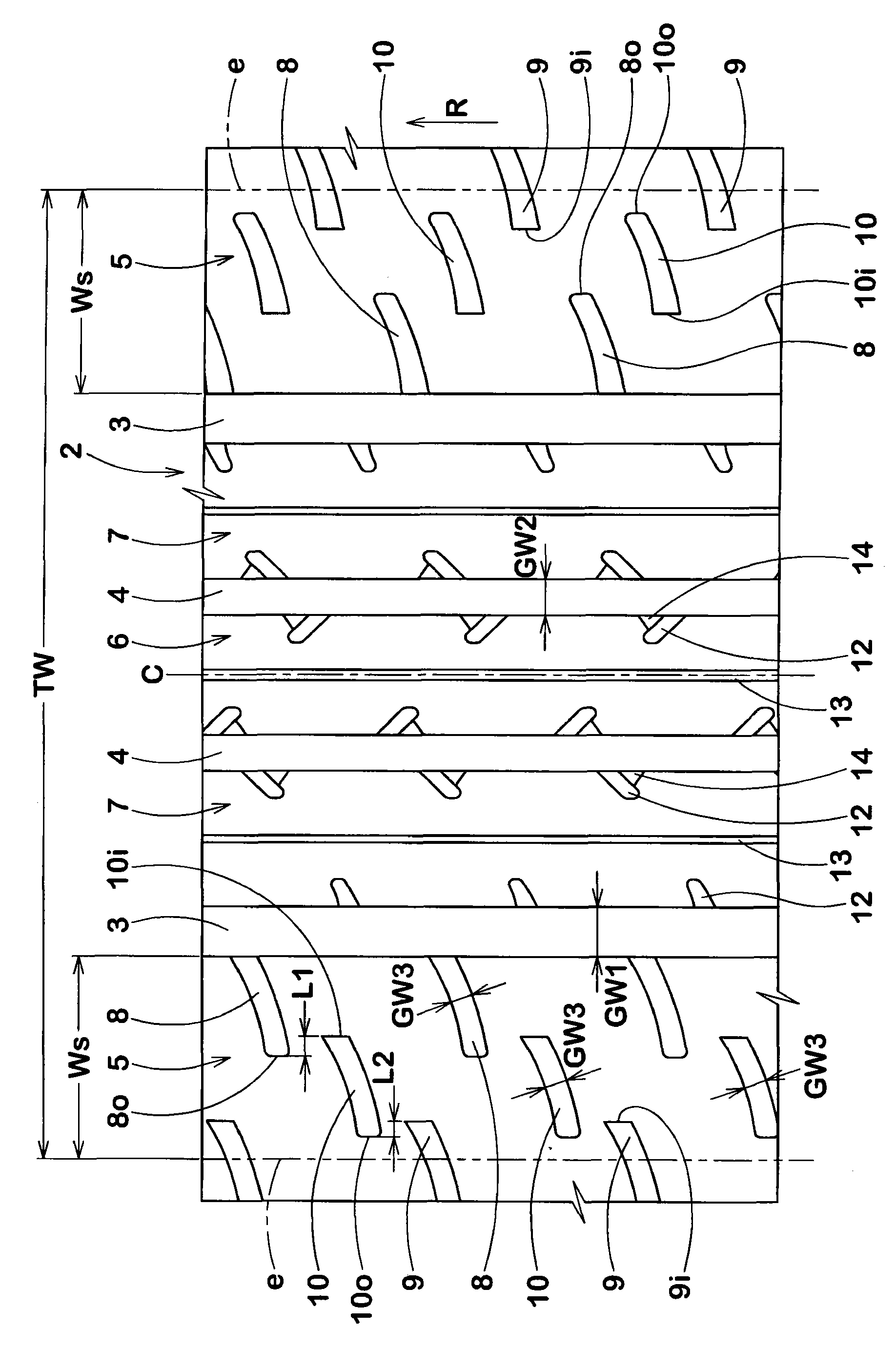

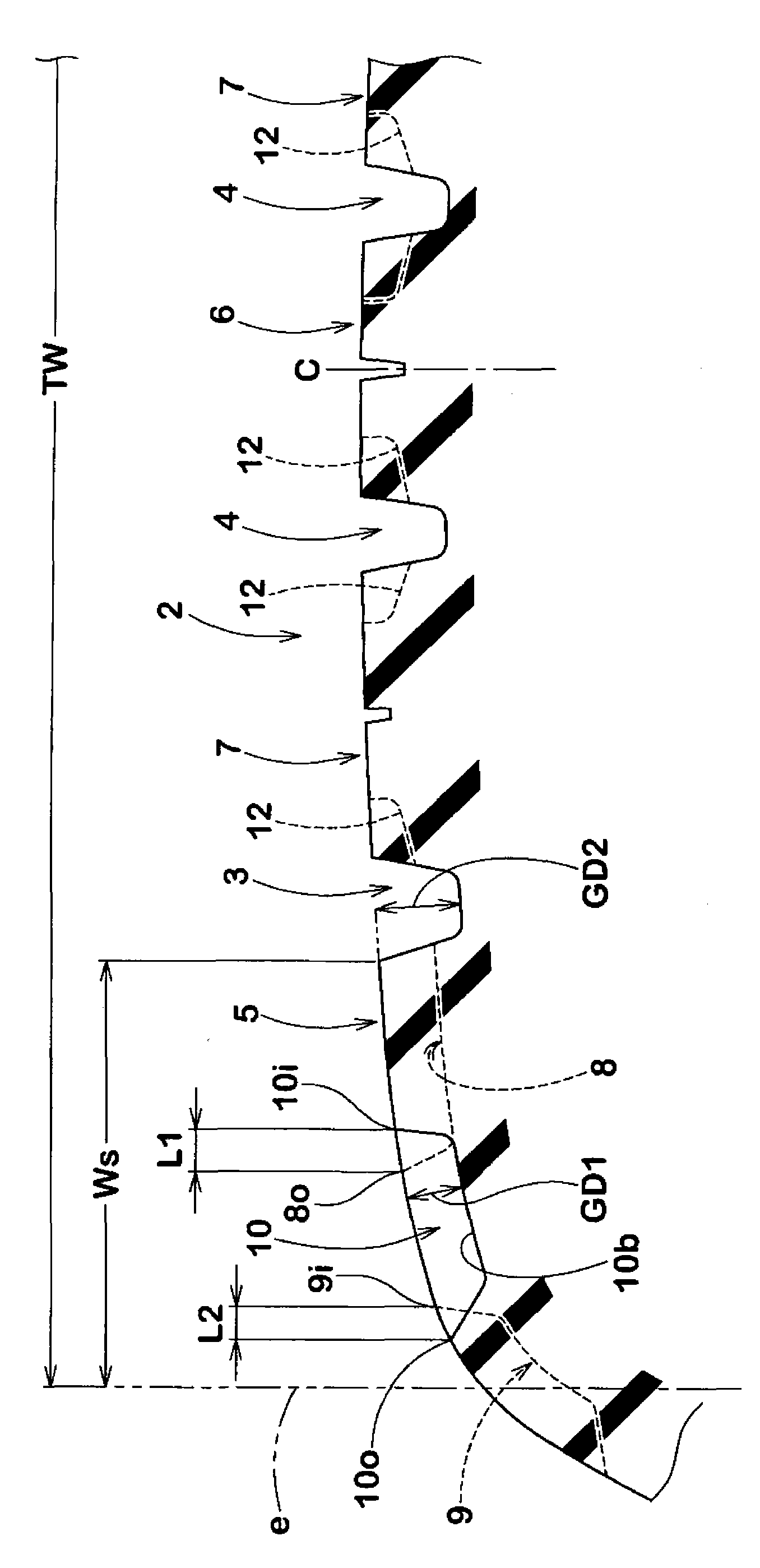

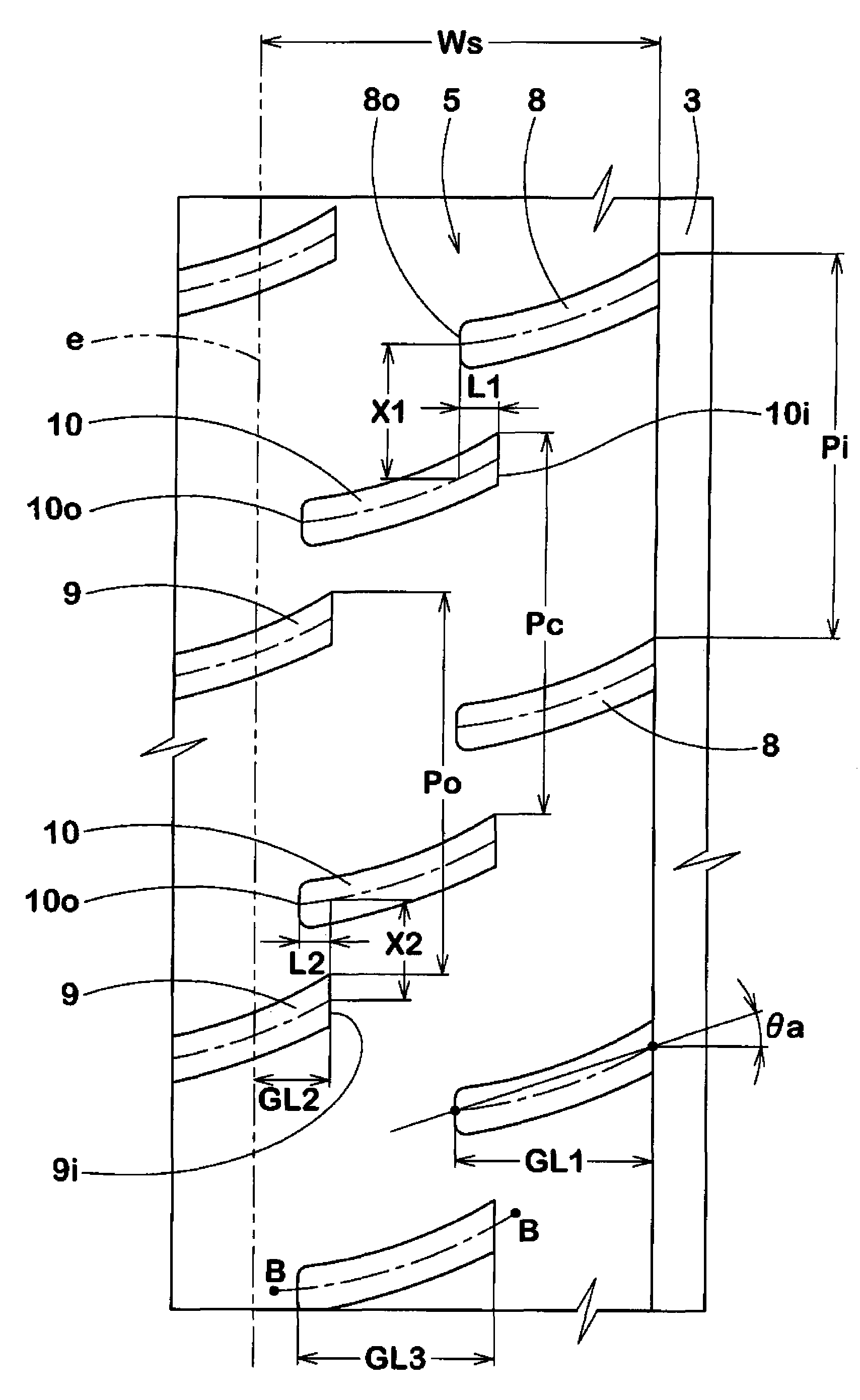

A technology of pneumatic tires and tires, applied in pneumatic tires, tire parts, tire treads/tread patterns, etc., can solve the problems of inability to maintain drainage performance, reduction of driving force and braking force, etc., to prevent the reduction of drainage performance , Improve the driving force or braking force, the effect of high tire circumferential rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] In order to confirm the effects of the present invention, radial tires for passenger cars with a tire size of 225 / 50R17 were trial-produced based on the specifications in Table 1. In addition, various properties were tested on them. The test method is as follows.

[0072] (heel toe wear)

[0073] Each test tire was mounted on the right front wheel of the vehicle under the following conditions, driven on the test course, and the toe side and The difference between the amount of friction on the heel side (heel-toe wear amount) was calculated, and their average value was calculated. The smaller the numerical value, the better.

[0074] Rims: 17×7.5J

[0075] Air pressure: 230kPa

[0076] Vehicle: Japan-made FR sedan with a displacement of 3000cc

[0077] Test route pavement: dry asphalt pavement

[0078] Driving distance: 7000km

[0079] (noise suppression performance)

[0080] Using a vehicle under the same conditions as above and running on a flat road at a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com