Cast-in channel

A technology of anchor rail and rail body, which is applied in the direction of construction and building construction, to achieve the effect of low manufacturing and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

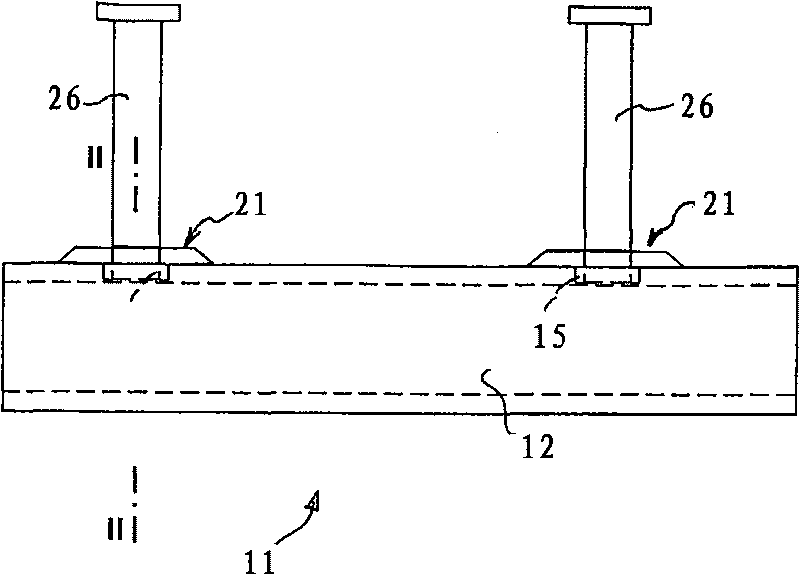

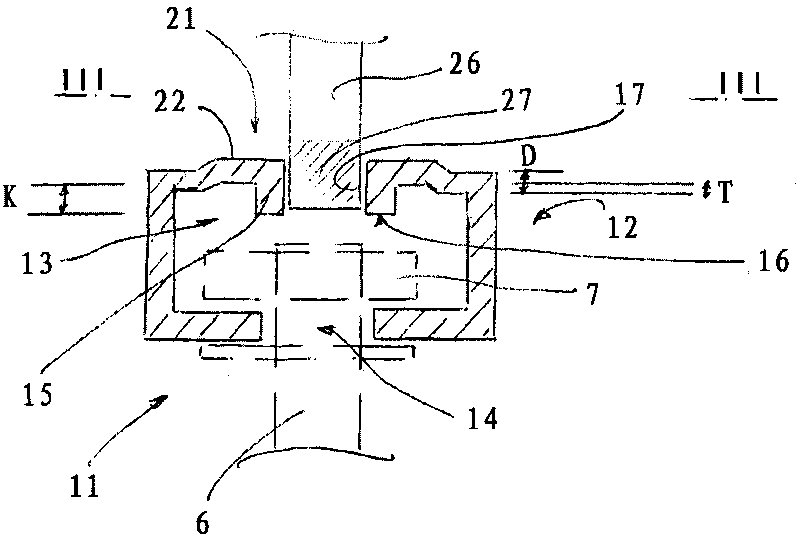

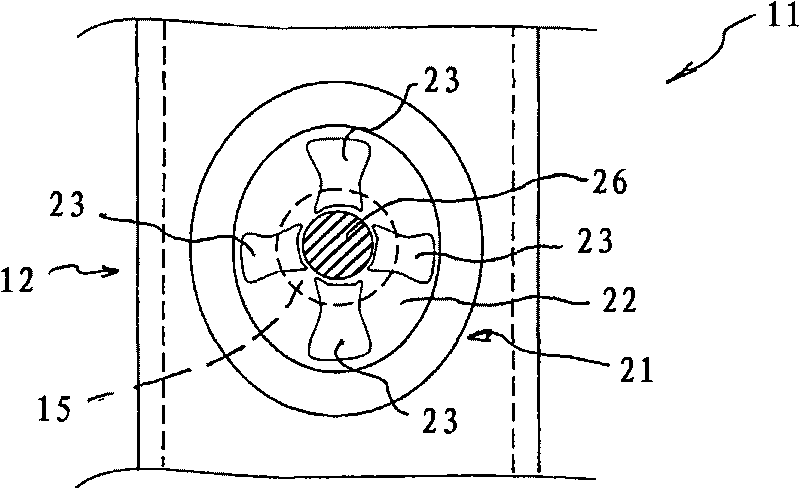

[0023] Figures 1 to 3 The anchor rail 11 shown in has a rail body 12 and a plurality of anchor elements 26 fastened thereon. The rail body 12 forms a receiving space 13 for receiving the tie element 7 for fastening the fastening element 6 on the anchor rail 11, wherein the receiving space 13 is accessible from the outside through a mounting opening 14 extending in the longitudinal direction of the rail body 12 .

[0024] Two outwardly directed recesses 21 are provided on the rail body 12 relative to the receiving space 13 and each have a base part 22 . A passage 15 provided with an internal thread 17 is provided in each bottom part 22 for fastening the anchor elements 26 , the free ends 16 of which are respectively oriented in the direction of the receiving space 13 . The bottom surface portion 22 of the groove 21 has a non-concentric structure in plan view with respect to the penetration 15 arranged therein. And the bottom surface portion 22 of the groove 21 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com