Poppet valve operated by an electrohydraulic poppet pilot valve

An electric and hydraulic technology, applied in the direction of valve operation/release device, lift valve, valve device, etc., can solve the problems of enlargement, precise control of adverse effects, short stroke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

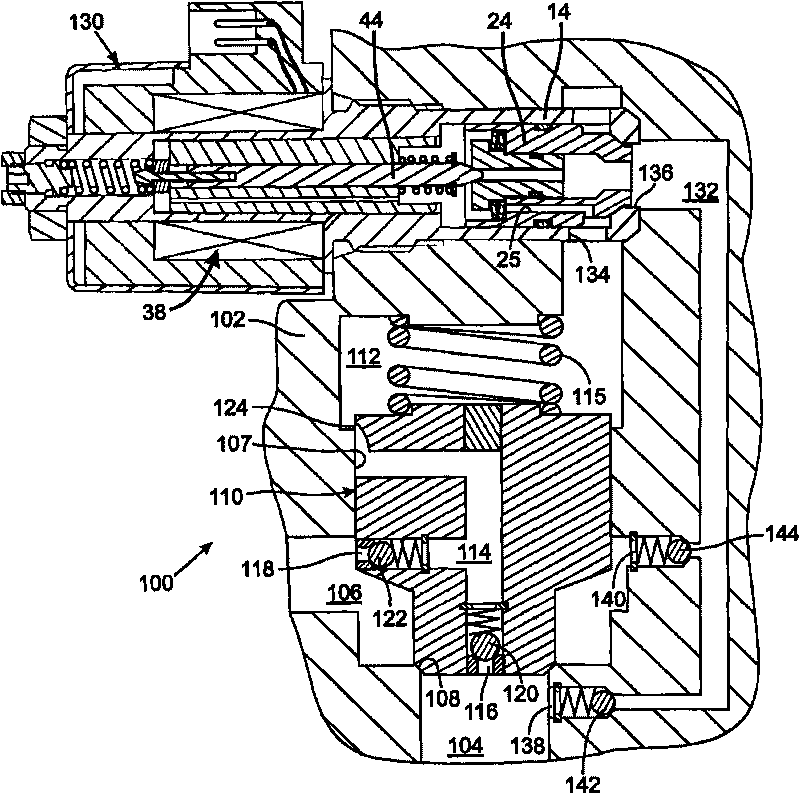

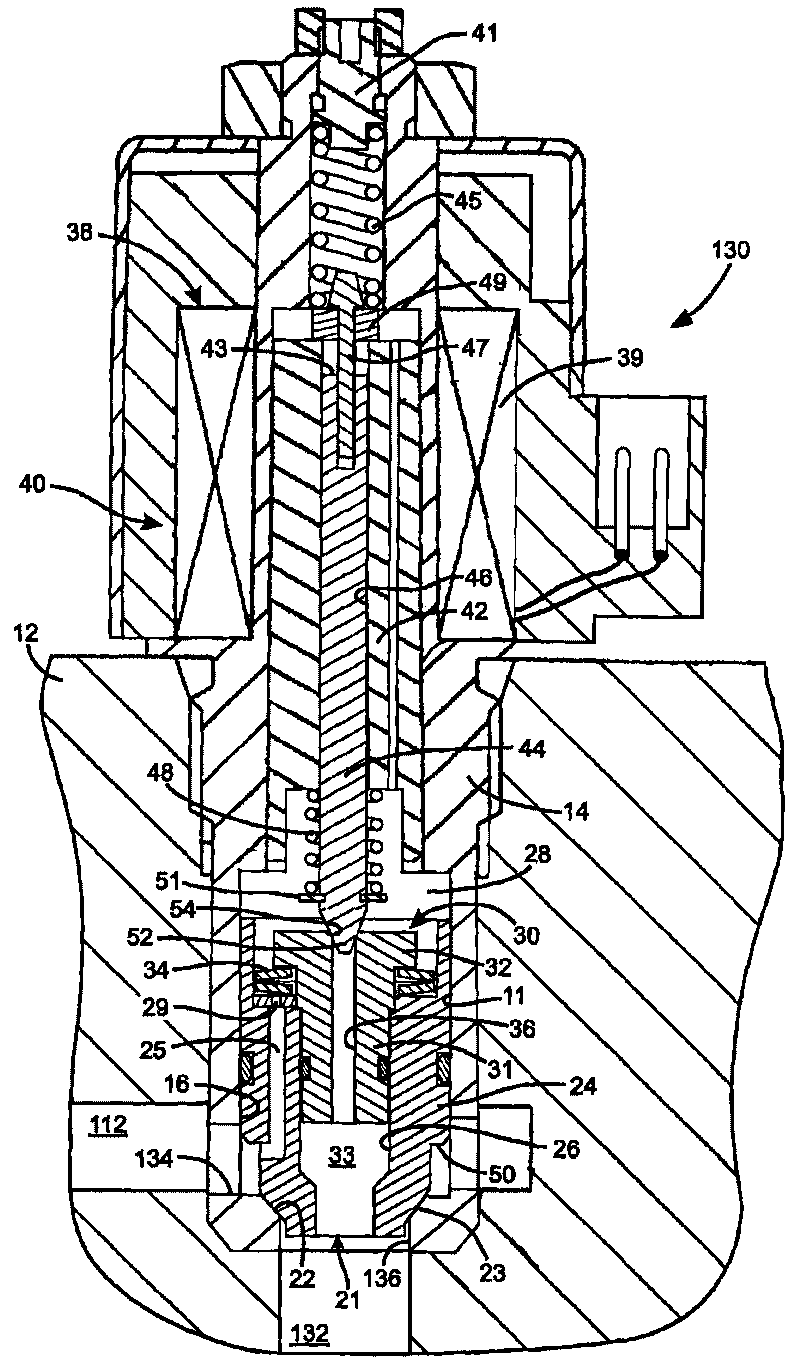

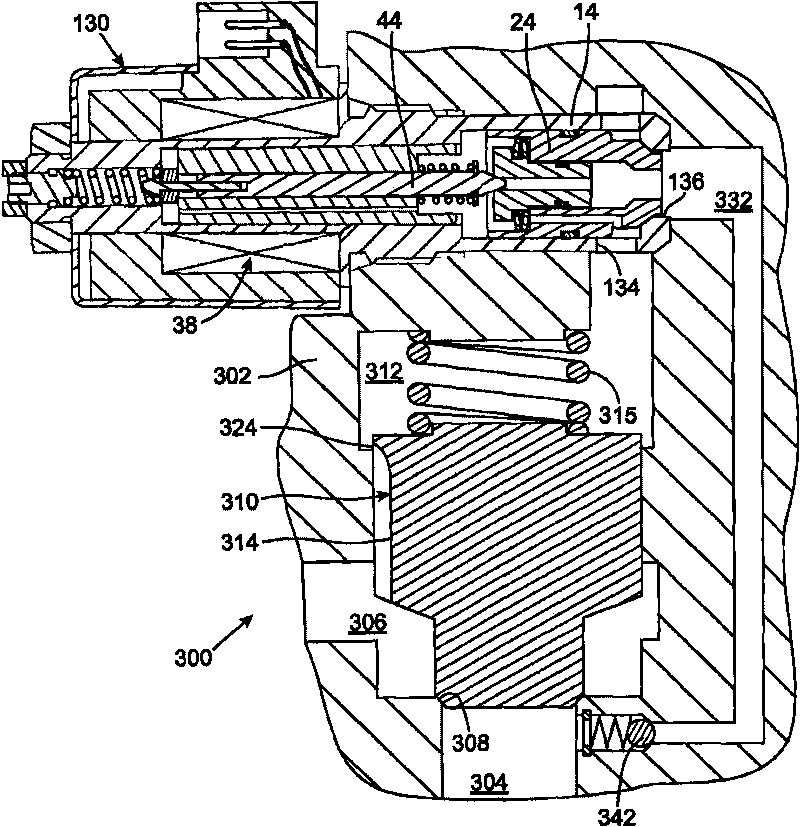

[0019] see first figure 1 , the two-way control valve 100 has a body 102 with a first port 104 and a second port 106 opening to a main hole 107 . The valve seat 108 is located between the first and second ports 104 and 106 . The main poppet 110 is slidably received in the body 102 and selectively cooperates with the valve seat 108 to close the fluid path between the first and second ports 104 and 106 . The main poppet 110 is slidable from engagement with the valve seat 108 to open the flow path between the first and second ports 104 and 106 . As will be described in more detail below, the movement of the main poppet is controlled by the main spring 115 and the main control chamber 112 in the first and second ports 104 and 106 connected to the side of the main poppet 110 away from the valve seat 108. Determined by the pressure relationship in the

[0020] The main poppet 110 has a passageway 114 with a first opening 116 into the first port 104 and a second opening 118 into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com