Test bench for prestressed anchor cable anchorage

A technology of prestressed anchor cables and test benches, which is applied in the field of mechanical test benches, can solve problems such as complex service conditions and inability to test the service life of anchor cables and anchors, and achieve the effect of accurate calculation data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

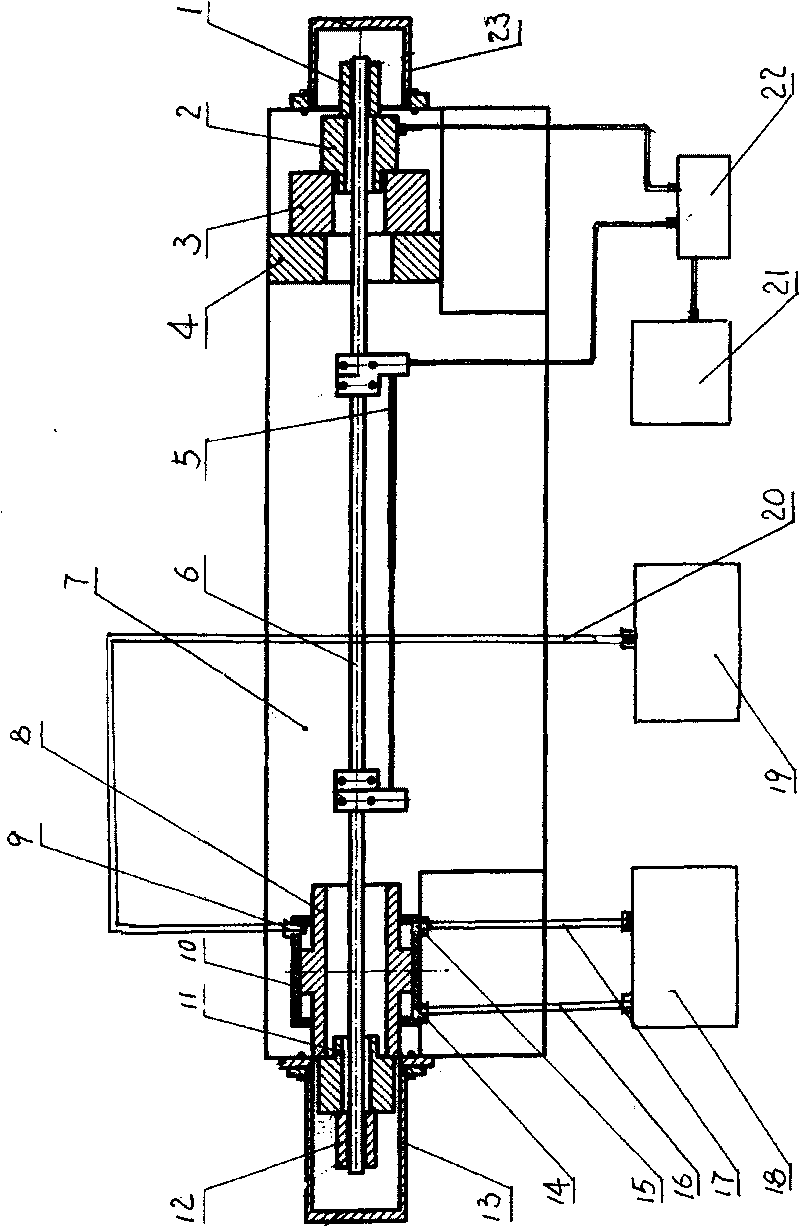

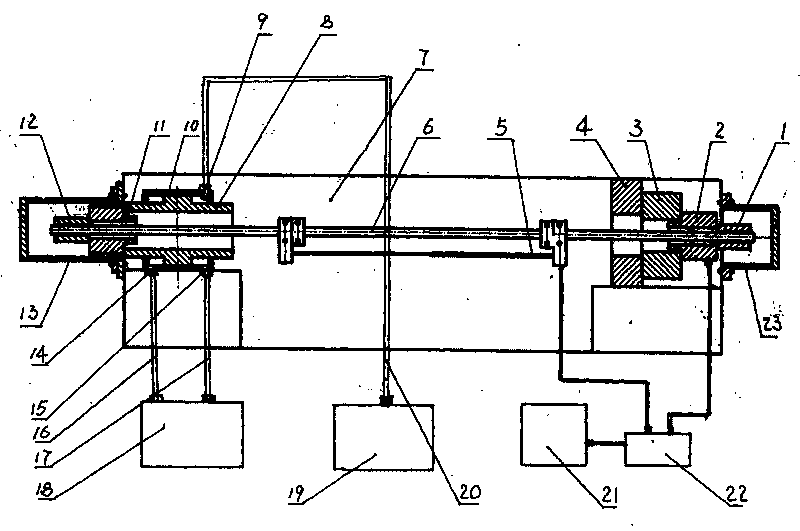

[0016] Such as figure 1 As shown, the prestressed anchor cable anchorage mechanical performance test bench of the present invention is composed of a static load hydraulic pump station 18, a fatigue load loading power source device 19, a test bench clamping device, a data detector 22 and a computer 21. in:

[0017] The net load hydraulic pump station 18 adopts a traditional hydraulic pump station with a working pressure greater than 5MP.

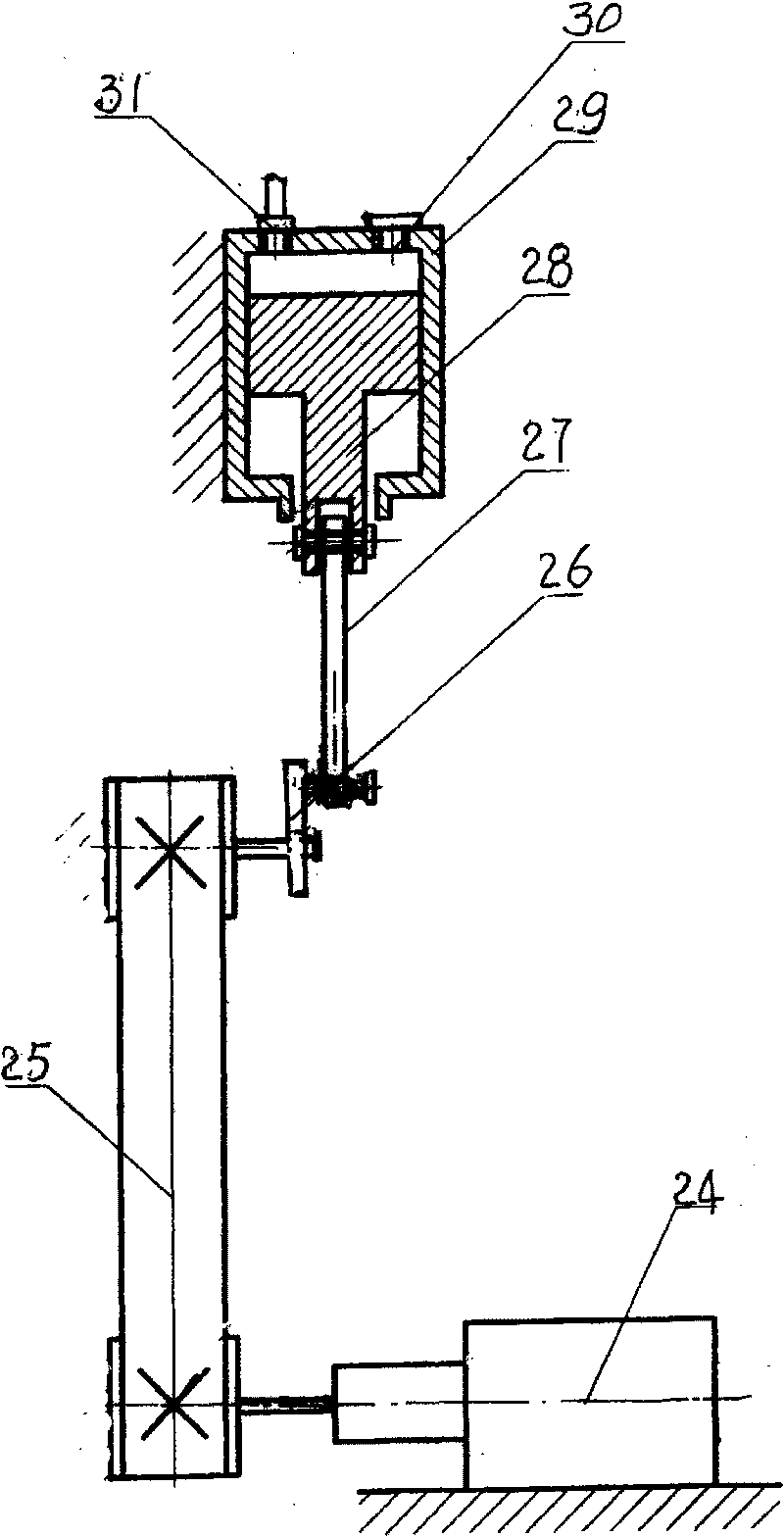

[0018] The fatigue load loading power source device 19 is a device for applying dynamic load to the cable anchorage. The structure of the fatigue load loading power source device 19 is as follows: figure 2 shown. Mainly by motor 24, belt drive 25 (including two pulleys and a belt), crank 26, connecting rod 27, piston pump cylinder 28 and piston 29 form. The motor 24 connects the motor shaft and the first pulley shaft through the flat key, and transmits the torque to the second pulley through the belt; the second pulley rotation shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com