Apparatus for heat exchange with radial mixing

An equipment, axial technology, applied in the field of equipment using radial mixing for heat exchange, which can solve the problem of peak loads on shafts and drives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that the drawings are merely schematic illustrations of preferred embodiments of the invention, which are described by way of non-limiting exemplary embodiments. In the drawings, the same or corresponding parts are denoted by the same reference numerals.

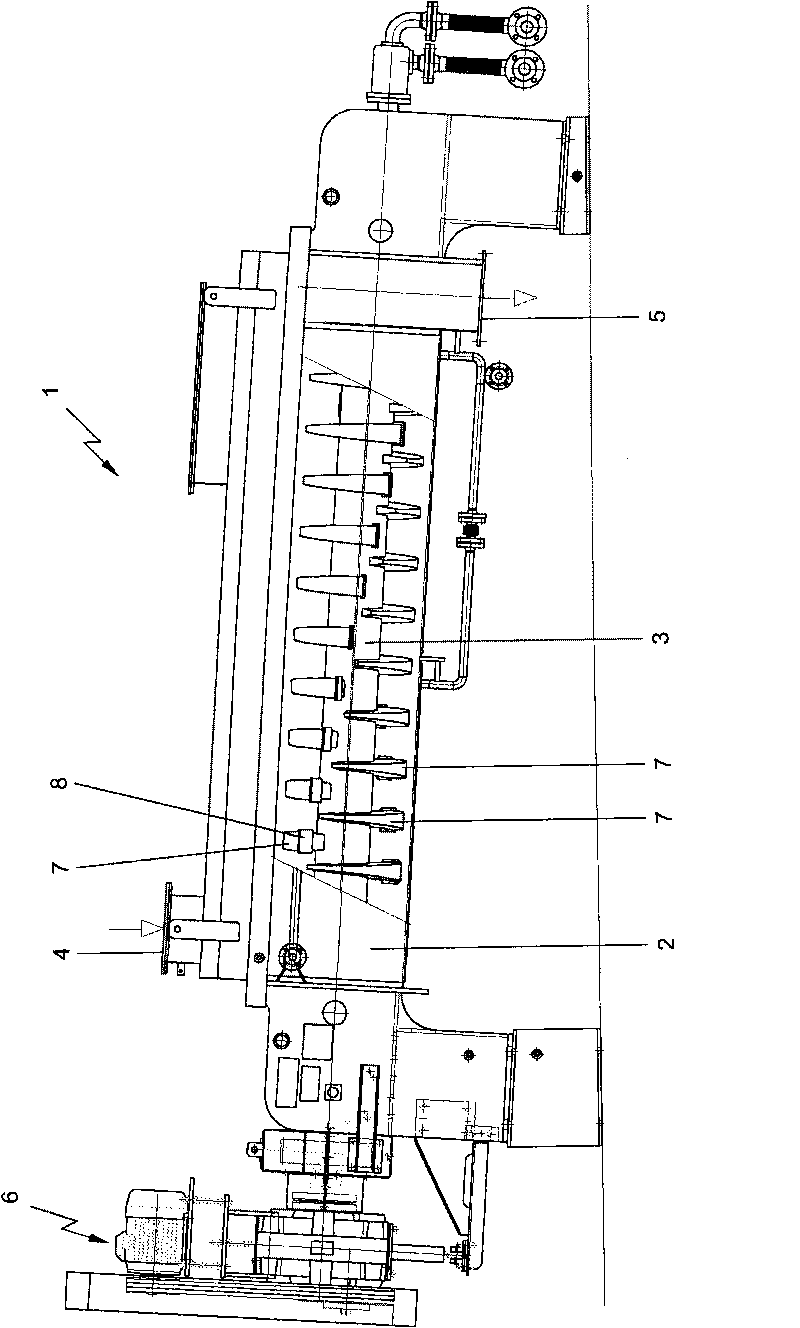

[0019] figure 1 A device 1 comprising a tank 2 is shown. exist figure 1 In , slot 2 is partially cut away so that shaft 3 can be seen. The slot 2 comprises two rotatably arranged shafts 3 extending alongside each other. The device 1 is provided with an inlet 4 along which the product to be processed is supplied into the tank 2 and an outlet 5 from which the product is discharged. The shaft 3 is arranged along a direction corresponding to the path between the inlet 4 and the outlet 5 of the tank 2 . Shaft 3 is driven by drive 6 .

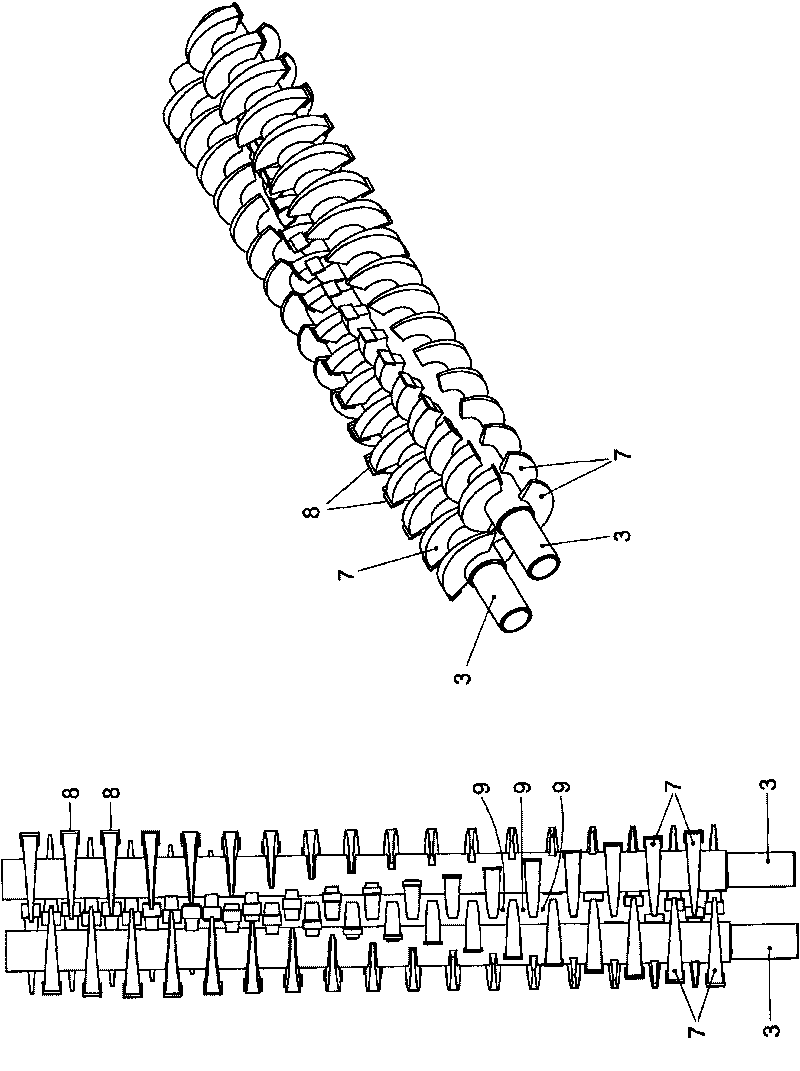

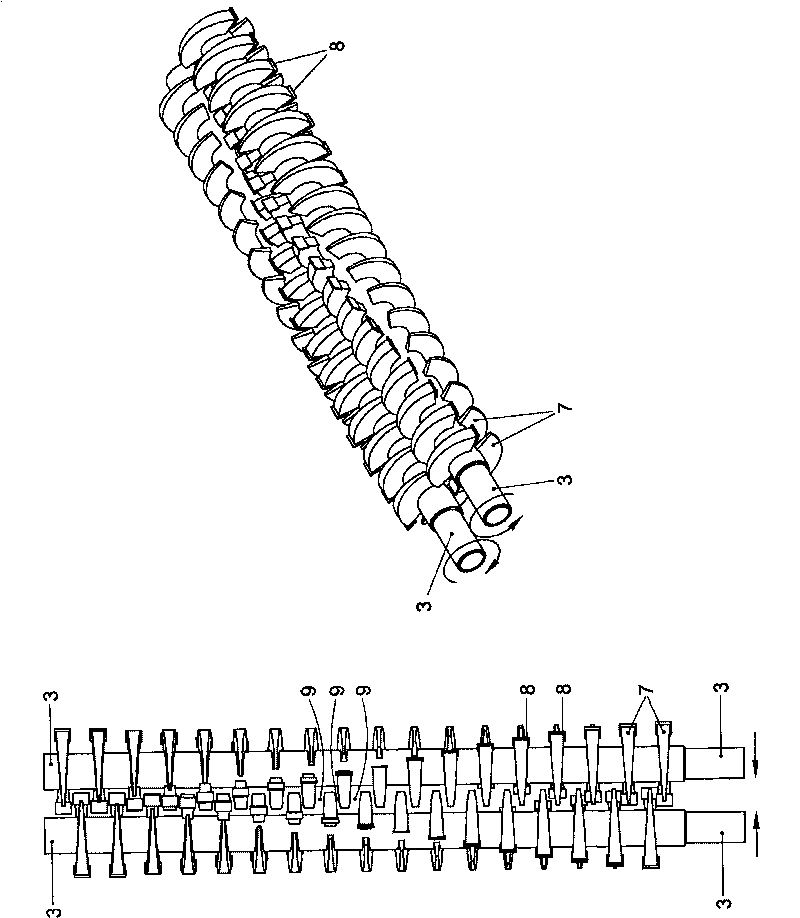

[0020] The shaft 3 is provided with blades 7 spaced axially at a moderate distance, and the blades 7 are arranged in a helical form, such as figure 1 shown. The bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com