Wind-speed adjusting device on tobacco processing equipment

A processing equipment and wind speed adjustment technology, which is applied in the fields of tobacco, cigarette manufacturing, transportation and packaging, etc., can solve problems such as unbalanced pipe network, air leakage in the silk collecting box, and wind distribution phenomenon, so as to ensure measurement accuracy, high adjustment accuracy, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

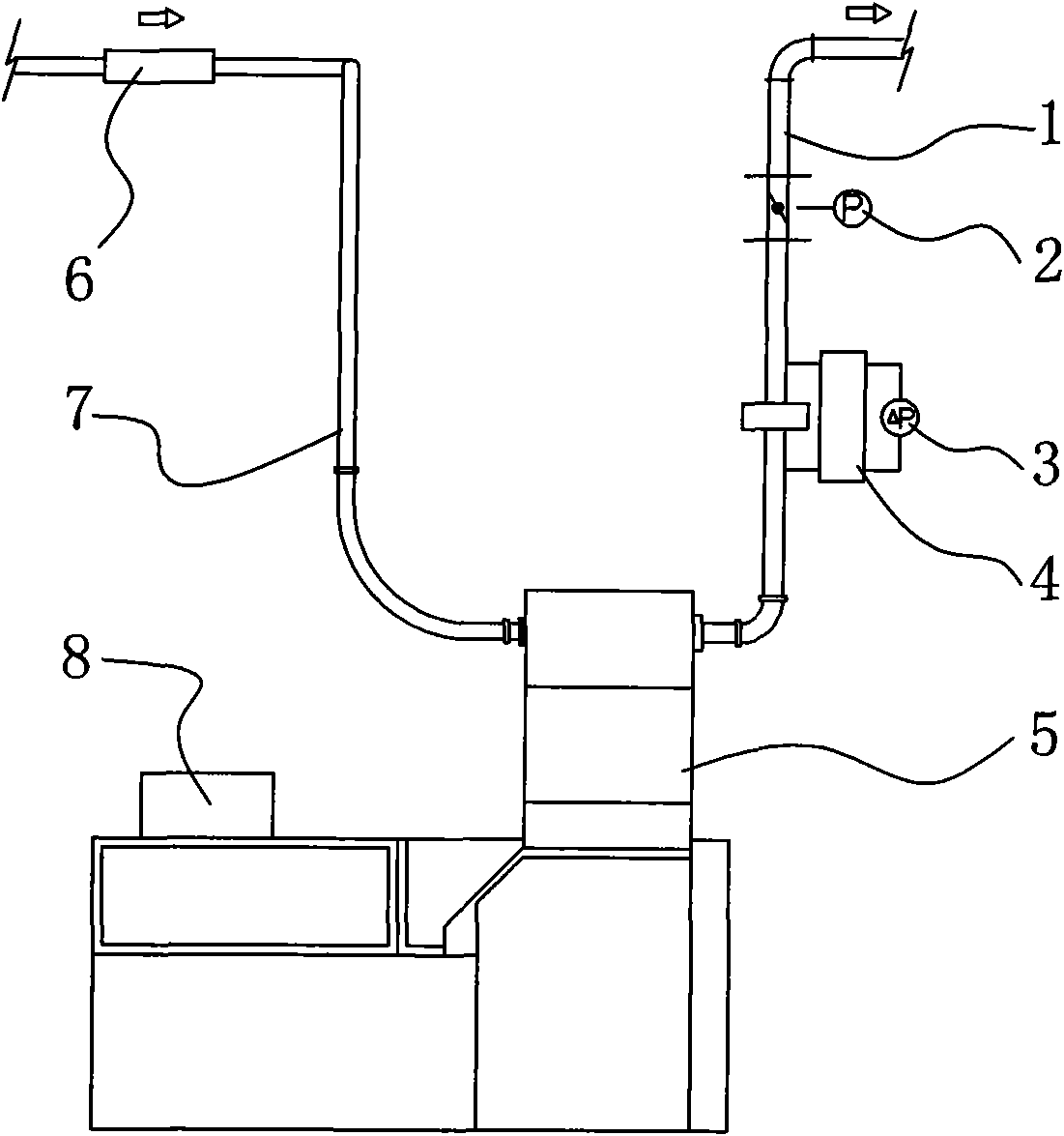

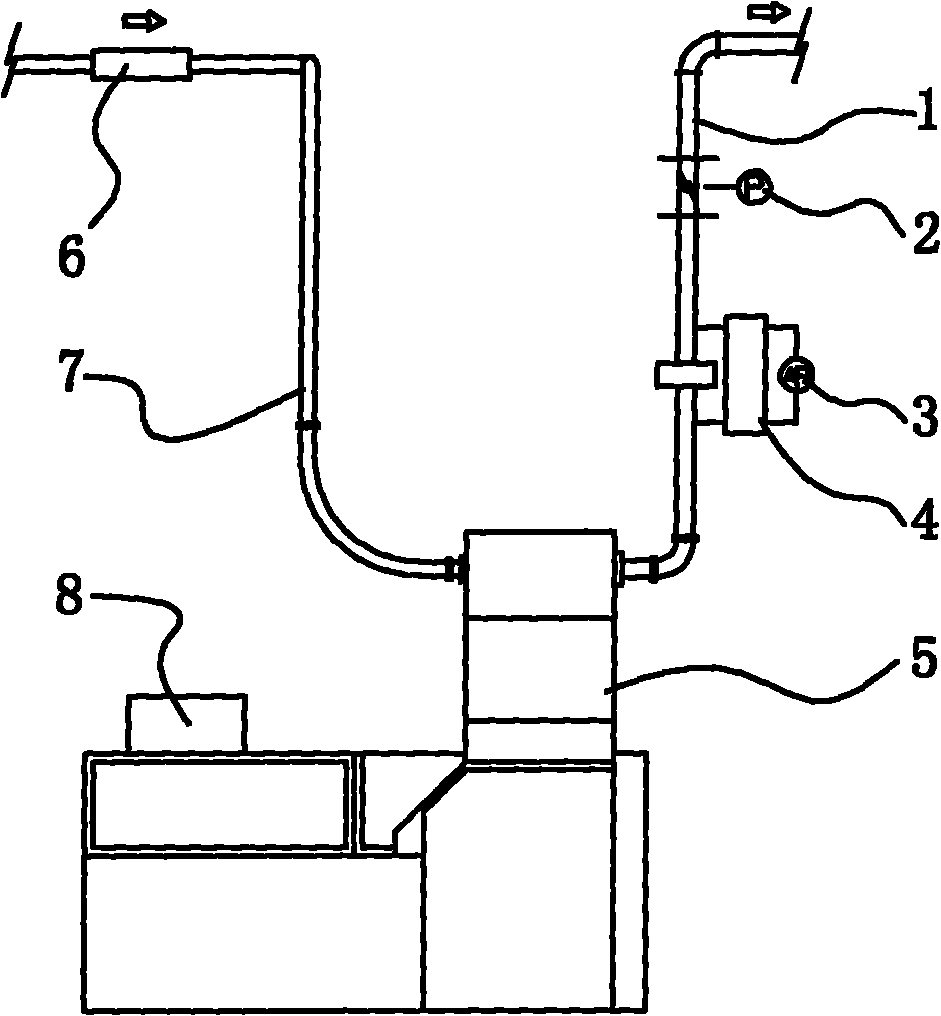

[0010] The invention as figure 1 As shown, it is arranged on the shredded tobacco conveying pipe 7 and the dust removal pipe 1 at both ends of the shredded tobacco processing equipment box 5, including a controller, an air leakage detection device 6, an anemometer 8, a flow meter 3, and a pneumatically adjustable butterfly valve 2; the air leakage detection device 6 is set on the shredded tobacco conveying pipe 7, the wind speed meter 8 is set on the silk collection box 5, the flow meter 3 and the pneumatic adjustment butterfly valve 2 are set on the dust removal pipe 1, the air leakage detection device 6, the wind speed meter 8, the flow meter 3 and the pneumatic adjustment Butterfly valve 2 is connected to the controller.

[0011] It also includes a compressed air blowback block 4 which is arranged on the flow meter 3 and connected with the dust removal pipe 1 and the flow meter 3 .

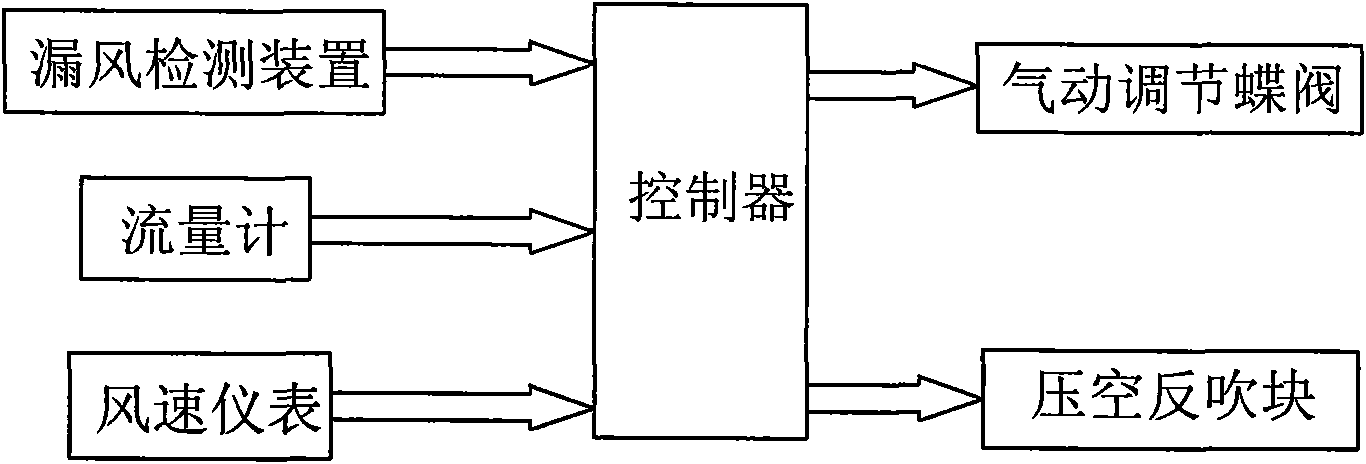

[0012] The working principle of the present invention is as figure 2 As shown, the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com