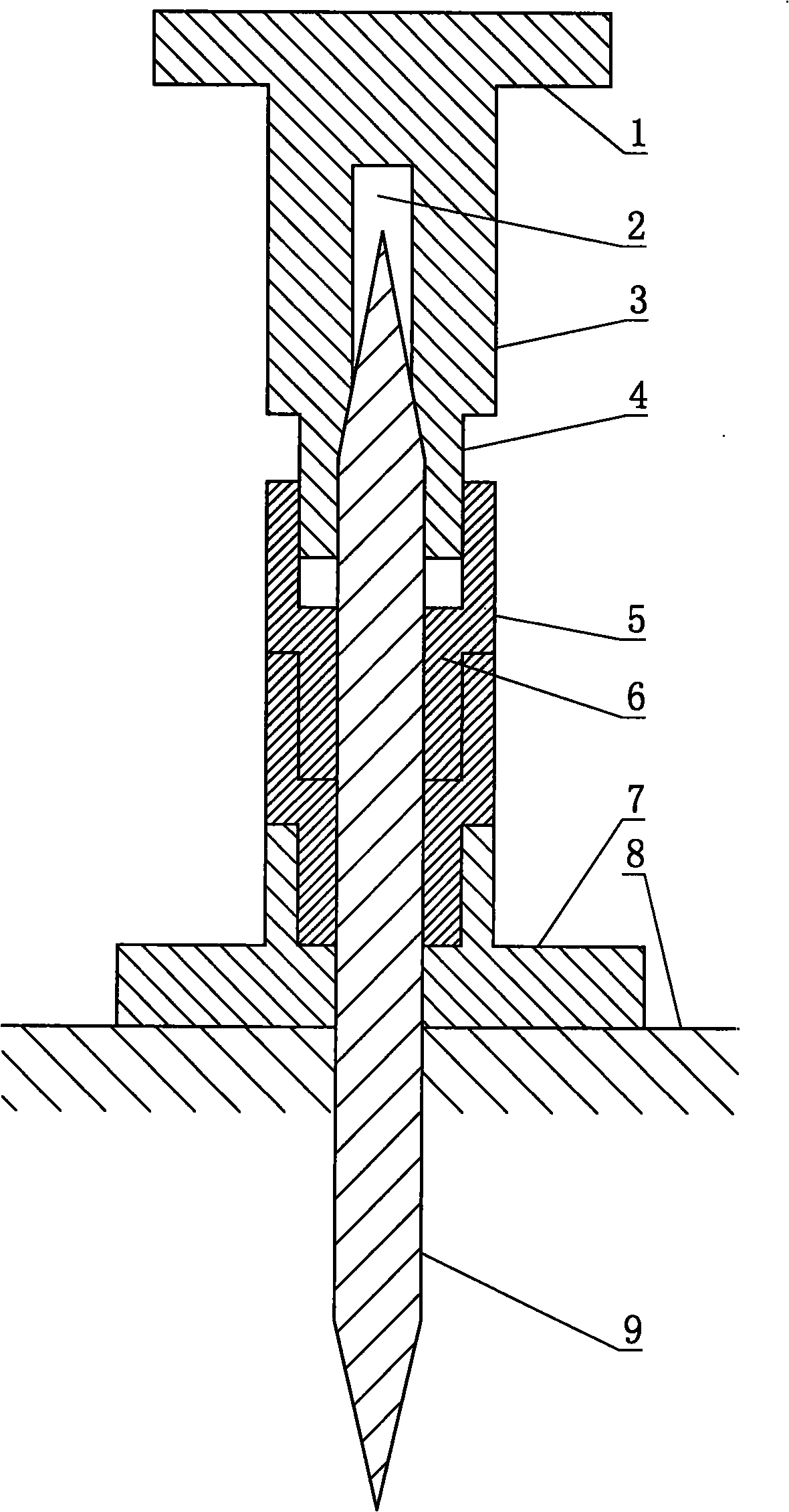

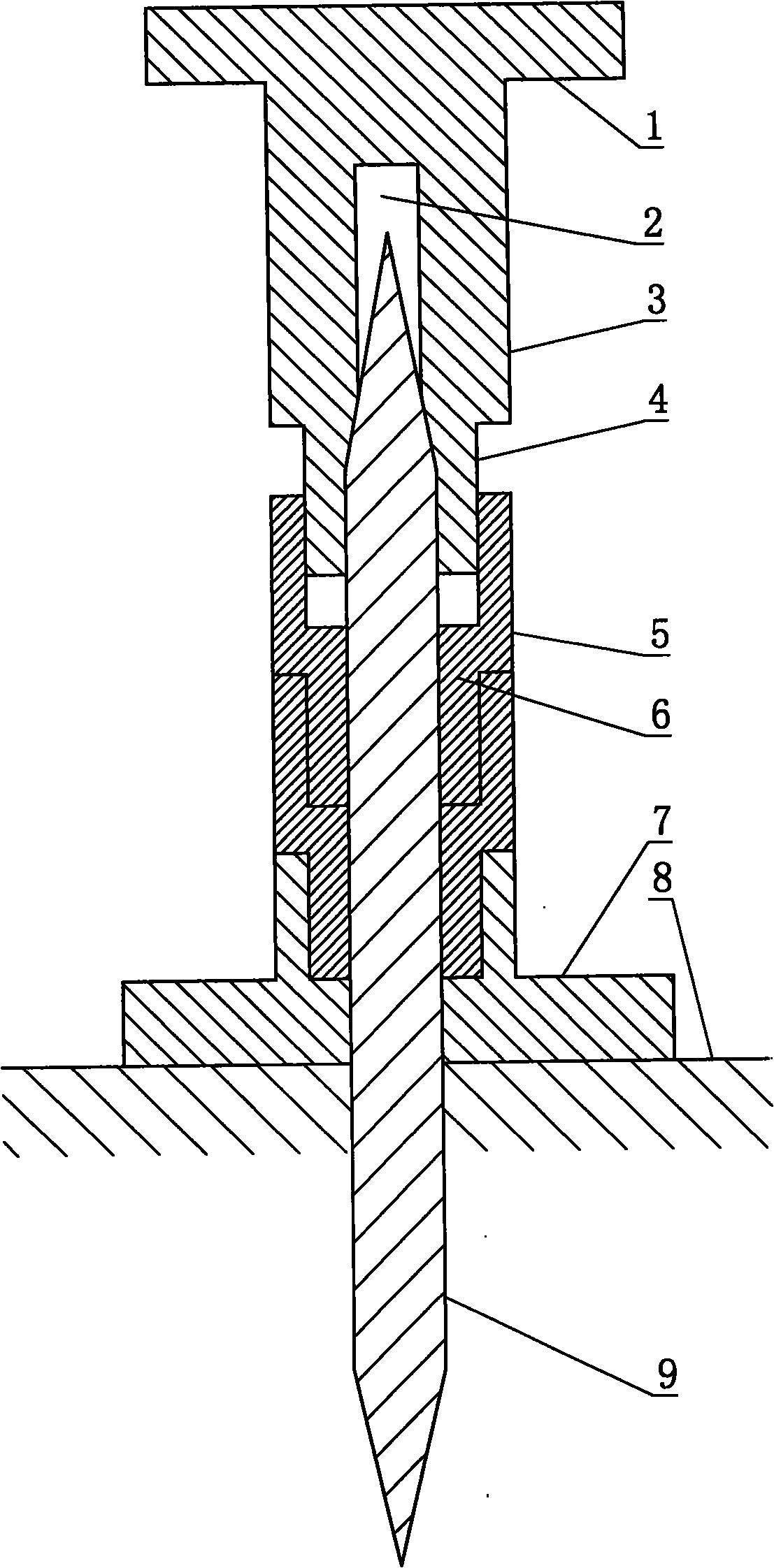

Axial drive-in stabilizer for double-headed nail

A double-headed and stable technology, applied in nail dispensers, packaging, manufacturing tools, etc., can solve the problems of time and material waste, reduce furniture quality, etc., and achieve the effect of avoiding waste, improving construction efficiency, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] The double-headed nail axially knocked into the stabilizer is composed of a nail cap 1, a thin shaft hole 2, a fixing cylinder 3, an inserting sleeve 4, a sleeve 5, a nail fixing cylinder 6 and a base 7. The nail cap 1 is disc-shaped, the bottom surface of the nail cap 1 is a cylindrical fixing tube 3 integrated with the nail cap 1, the thin shaft hole 2 is a blind hole at the axis center of the fixing tube 3, and the diameter of the thin shaft hole 2 Less than the diameter of the stud 9. The lower end of the fixed cylinder 3 is a cylindrical insertion sleeve 4 which is integral with the fixed cylinder 3 and has a smaller outer diameter than the fixed cylinder 3 and a larger inner diameter than the thin shaft hole 2 . The junction of the inner hole of the inserting sleeve 4 and the thin shaft hole 2 transitions through a ring-shaped slope, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com