Adjusting device for correcting deviation of steel band by adjusting feeding shaft

A technology for adjusting devices and feed shafts, which is applied to household components, flat products, household appliances, etc., can solve problems such as non-stop adjustment, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

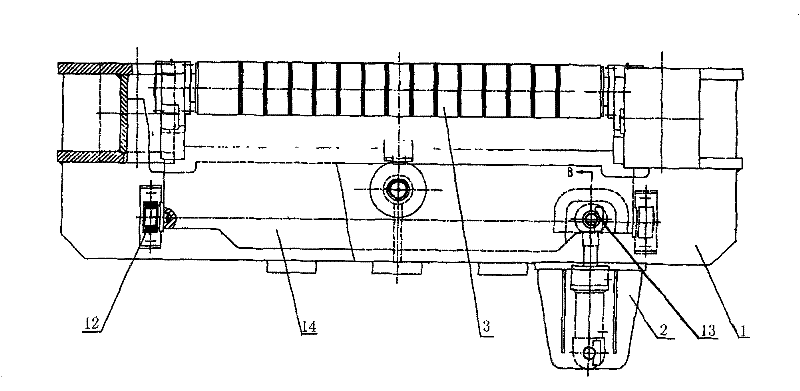

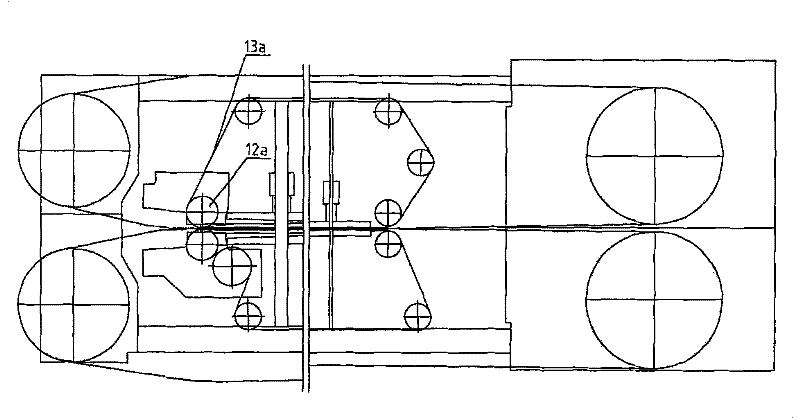

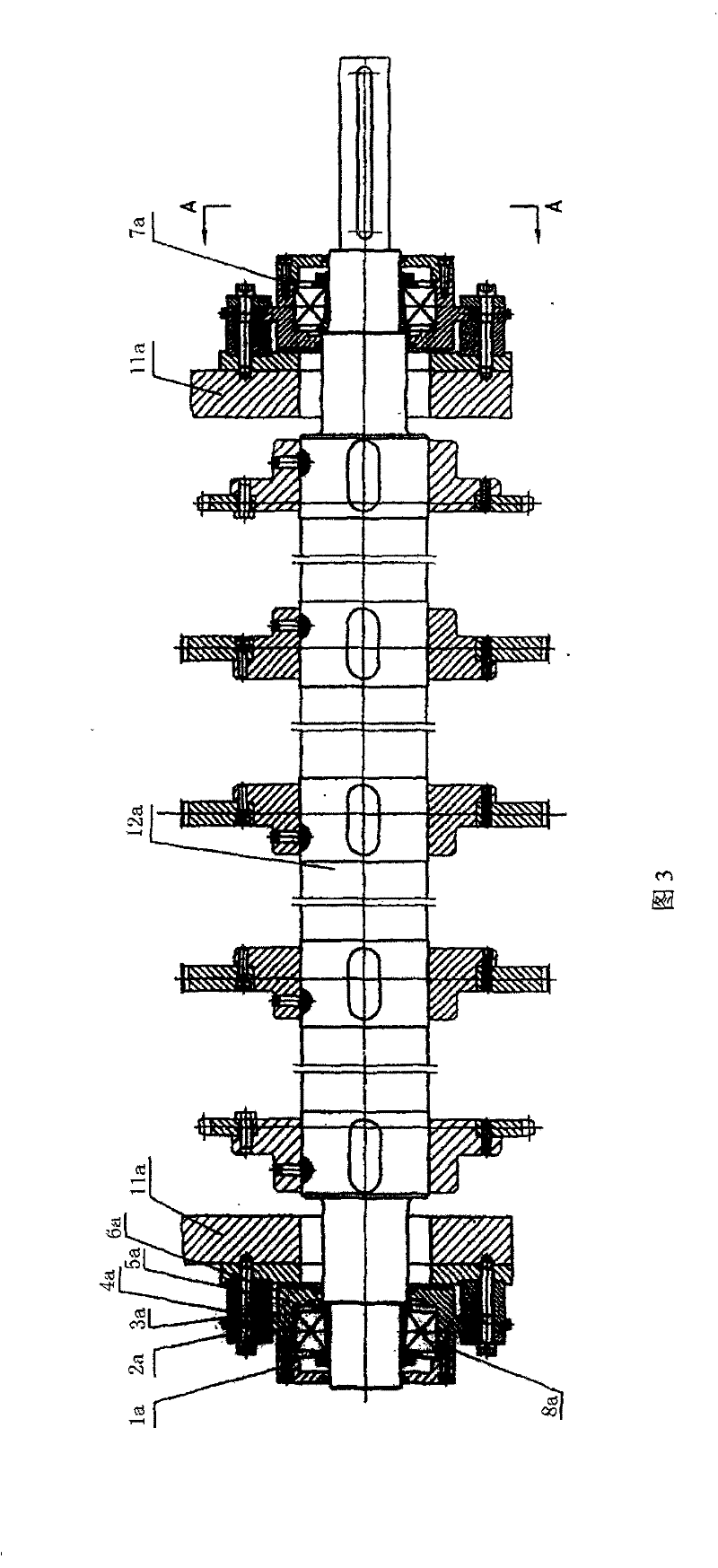

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] The adjustment device for correcting the deviation of the steel strip by adjusting the feed shaft is usually a group, which is arranged at one end of the feed shaft 12a. Adjust the bearing seat 6a at one end of the feed shaft 12a, so that the verticality between the axis of the feed shaft 12a and the working direction can be fine-tuned, and then the steel belt 100 can be adjusted by adjusting the deflection of the cylindrical small roller in the chain blanket 13a. Correction.

[0031] see Figure 5, each group of adjustment devices that implement correction to the steel strip by adjusting the feed shaft includes a steel strip deviation detection mechanism 200, and the sensor (not shown in the figure) in the steel strip deviation detection mechanism 200 is installed in a flat pressure On the frame (not shown in the figure) of continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com