Automatic deviation correction device for amorphous strip coiling

An automatic rectification device, a technology of amorphous strips, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of inability to adapt to continuous production, not suitable for high-speed production, poor reliability, etc., and achieve a simple structure. , Low cost, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

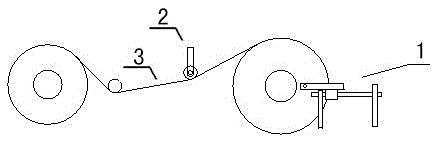

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

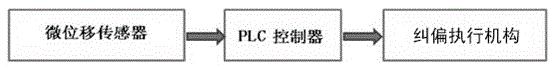

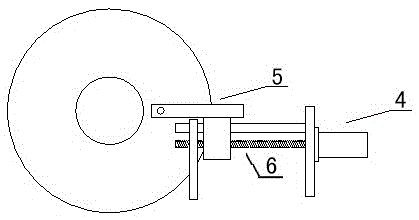

[0026] The technical solution of this embodiment is: an automatic deviation correction device for amorphous strip coiling, including a moving mechanism, a deviation correcting actuator and a control mechanism; the moving mechanism is responsible for moving following the radial deviation of the coiled amorphous strip , and detect the axial offset of the strip; the control mechanism controls the action of the deviation correction actuator according to the axial offset of the strip; the deviation correction actuator pushes the strip to make corresponding adjustments.

[0027] Wherein, the moving mechanism includes a servo motor, a micro-motion sensor and a lead screw, and the servo motor drives the micro-motion sensor to move along the lead screw.

[0028] Wherein, the control mechanism includes a PLC controller.

[0029] Wherein, the control mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com