Riveting device and method for locking bearing case assembly and liner assembly

A technology for riveting devices and components, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of uneven force, low production efficiency, high production cost, etc., to avoid radial offset, uniform force, The effect of increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] The purpose of the present invention is to provide a riveting device and method for locking and supporting the casing assembly and the bushing assembly, which can realize the automatic centering of the supporting casing, the bushing and the spacer bushing, and can realize the simultaneous application of loads on the points so that the Each component is evenly stressed, avoiding radial deviation of each component during the riveting process, ensuring the riveting design requirements of the assembly, improving assembly quality, shortening assembly cycle, thereby improving production efficiency and reducing production costs.

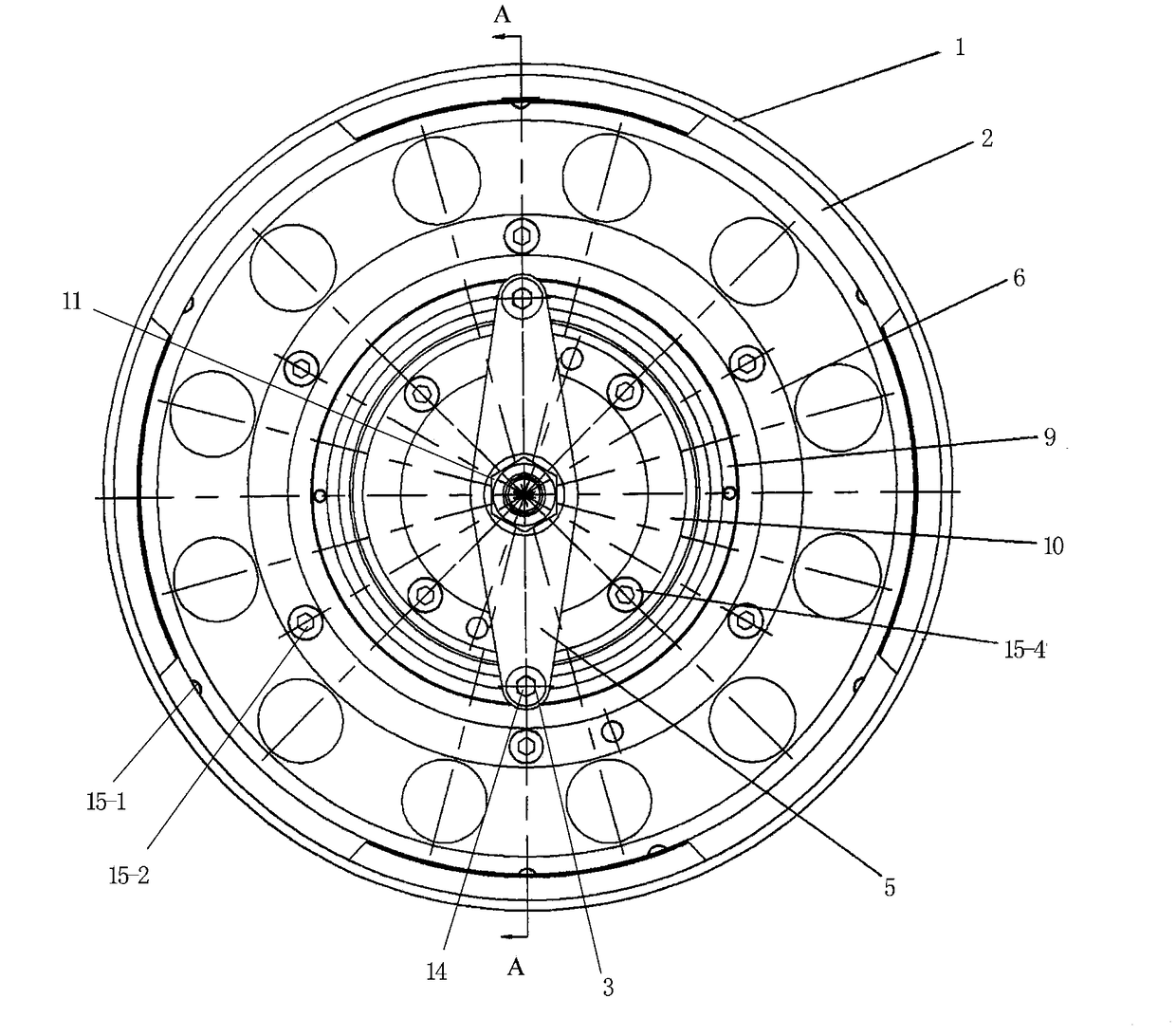

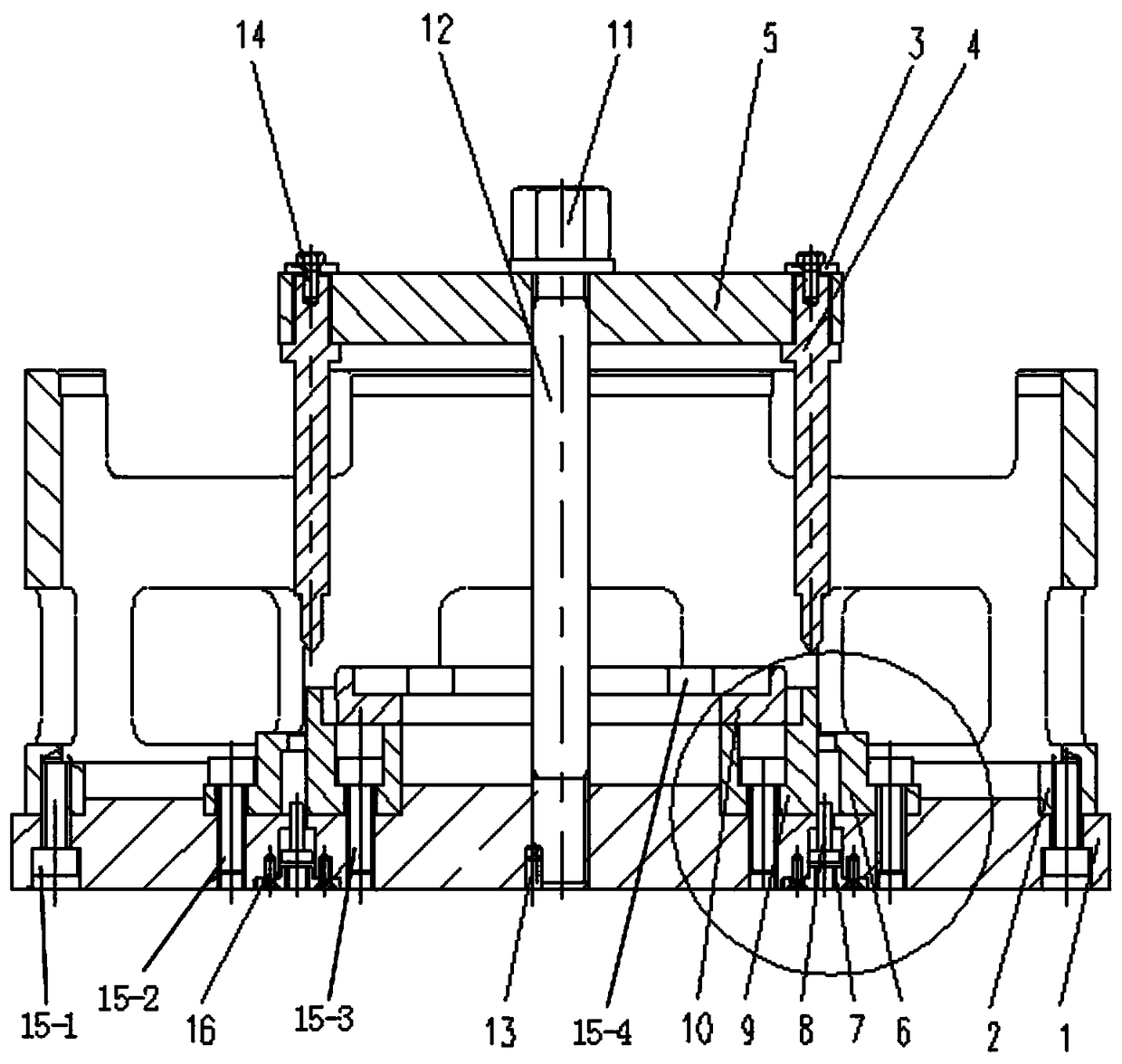

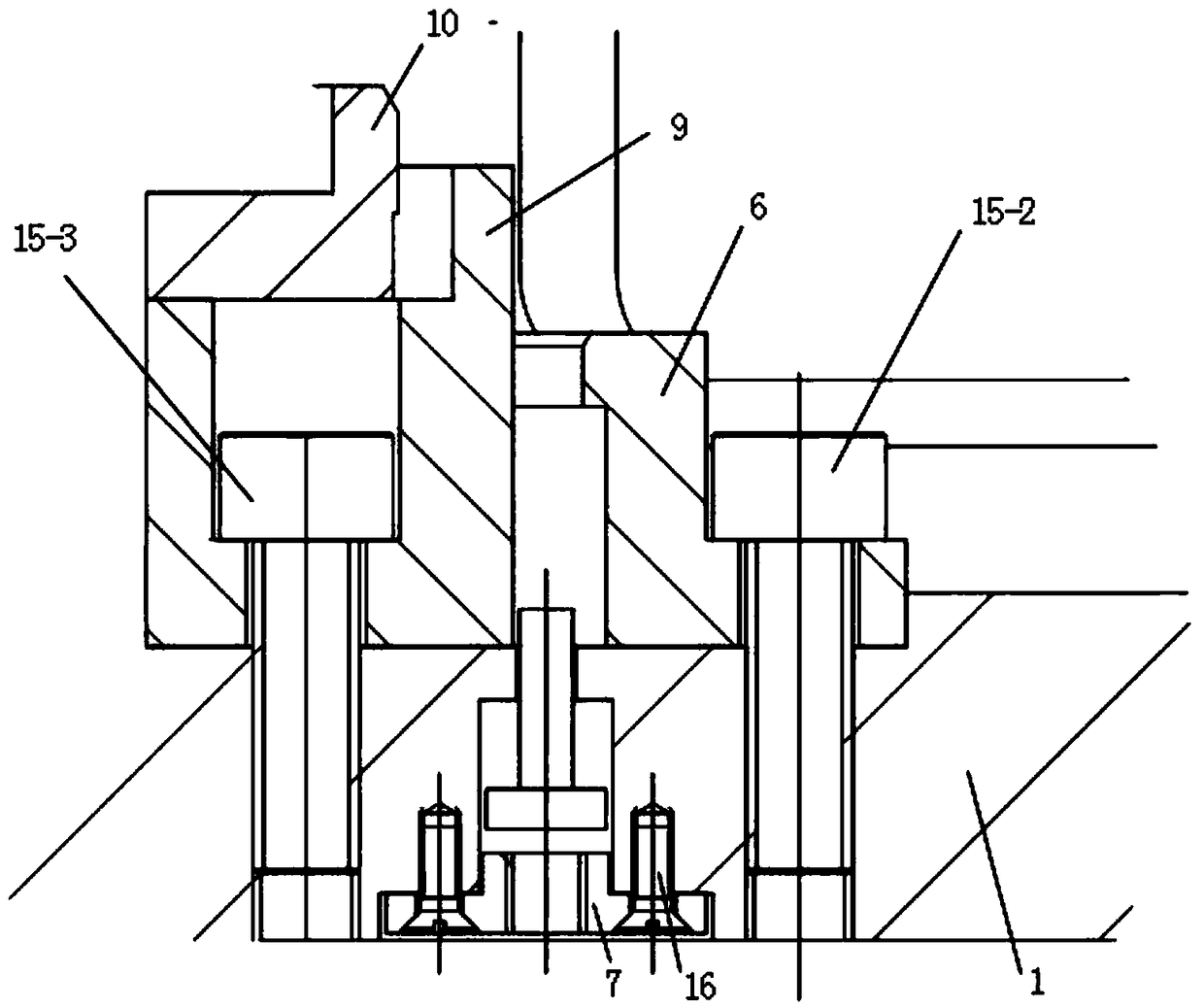

[0033] Such as figure 1 and figure 2As shown, they are the top view and the A-A sectional view of the riveting device for locking and supporting the casing assembly and the bushing assembly of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com