Ceramic bearing type reaction kettle

A technology of ceramic bearings and reactors, applied in chemical/physical/physicochemical fixed reactors, dissolution, mixers, etc., can solve the problems of aggravated bearing wear, increased eccentricity, and large diameter of the agitator to avoid damage , prolong service life, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

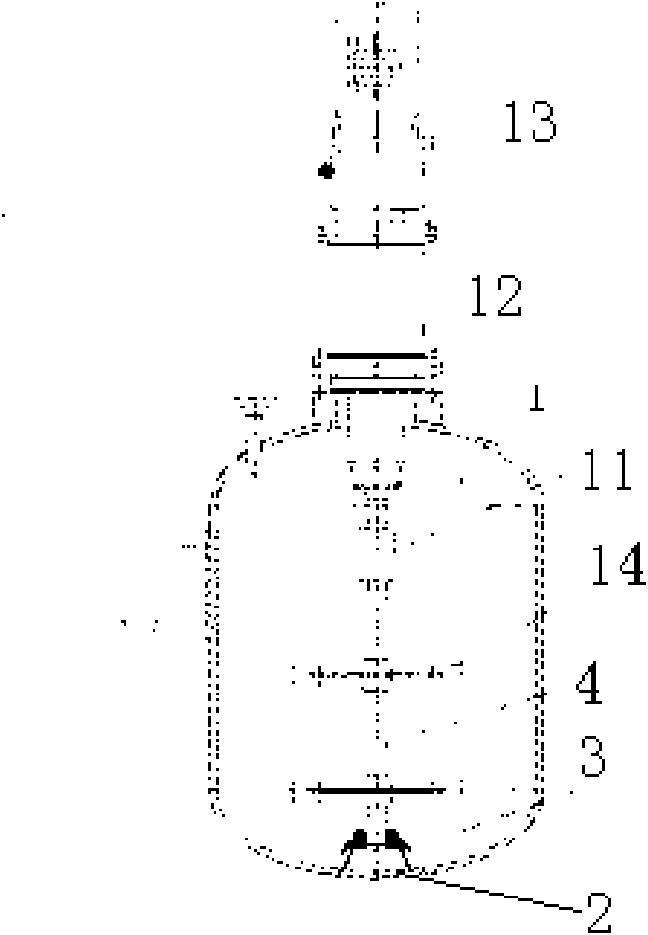

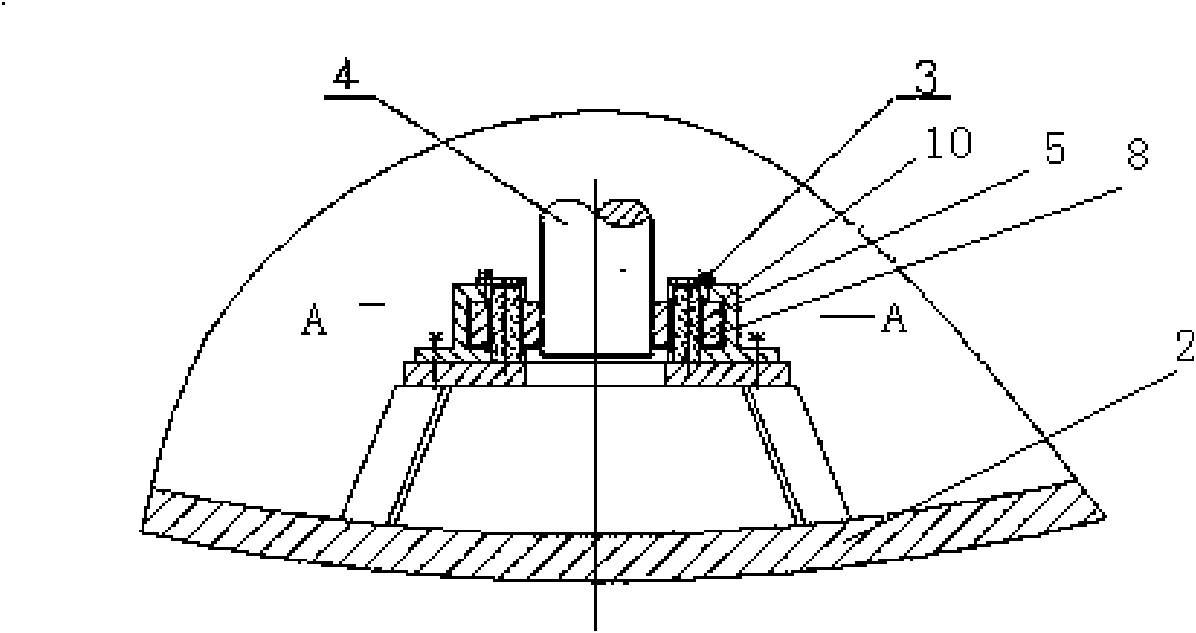

[0020] As shown in the figure: a ceramic bearing type reactor, including a kettle body 1, a power device 13, a power transmission device 12, a coupling 11, a stirring shaft 4, and an agitator 14. The above is the same as the prior art, and will not be repeated here. , the feature of the present invention is to be provided with the bottom supporting bearing device 3 that is made up of kettle body bottom plate 1, support frame 10, ceramic shaft 5, ceramic ring 8 and stirring shaft 4, form with stirring shaft 4 as inner ring, ceramic shaft 5, The ceramic ring 8 is a ball, the support frame 10 is a ball support, the bottom plate of the reaction kettle 2 is used as the rolling bearing of the outer ring, the ceramic shaft 5 and the ceramic ring 8 move relative to each other, and the ceramic ring 8 and the stirring shaft 4 make a rotary motion, realizing The transformation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com