An outstretched bottom-supported reactor

A technology of reactor and kettle body, which is applied in the field of separation, extended bottom-supported reactor, and high-performance fluid mixing. It can solve the problems of poor effect, uneven cooling, and inconvenient maintenance, so as to achieve convenient manufacturing and overcome easy breakage. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

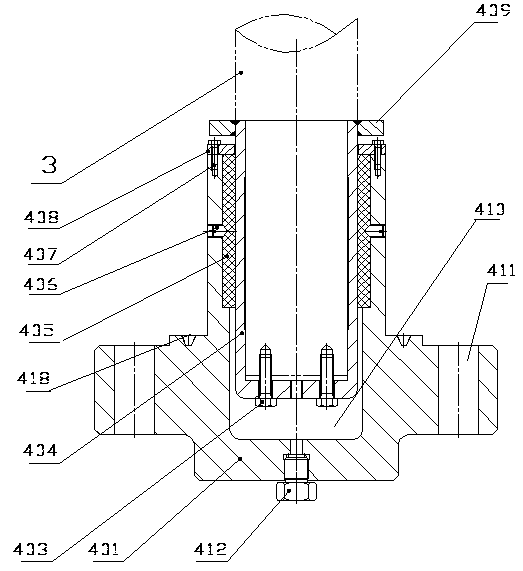

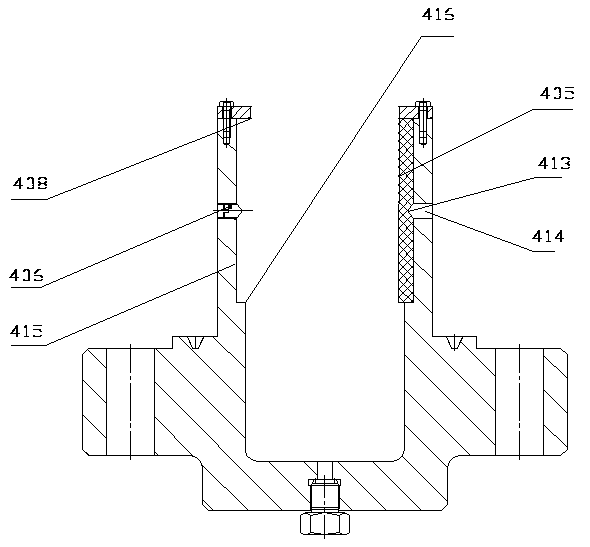

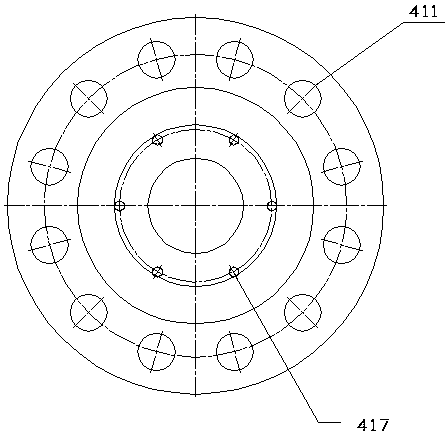

[0038] The structure of a kind of outstretched bottom support type reactor of the present invention is as follows: figure 1 As shown, it includes the reactor body 8, the power unit 1, the power transmission unit 2, the stirring shaft 3 and the coupling 5. The connection relationship between these components belongs to the prior art and will not be repeated here.

[0039] The power of the power device 1 is transmitted to the stirring shaft 3 through the power transmission device 2. The bottom support of the stirring shaft in the present invention is an outstretched bottom support 4, which is composed of a bearing seat 401, a protective sleeve 404 and a shaft sleeve ring 405. The main structure, the stirring shaft 3 passes through the bottom of the kettle body 2, and is installed in the bottom support 4 that limits the radial swing of the stirring shaft.

[0040] The bearing seat 401 of the bottom support 4 of the present invention has a cylindrical cavity 410, the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com