Sewing machine

A technology for sewing machines and sewing objects, which is applied in the field of sewing machines, can solve the problems of large manpower consumption and easy detection omissions, and achieve the effect of eliminating a large amount of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] (Overall structure of the sewing machine of this embodiment)

[0033] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

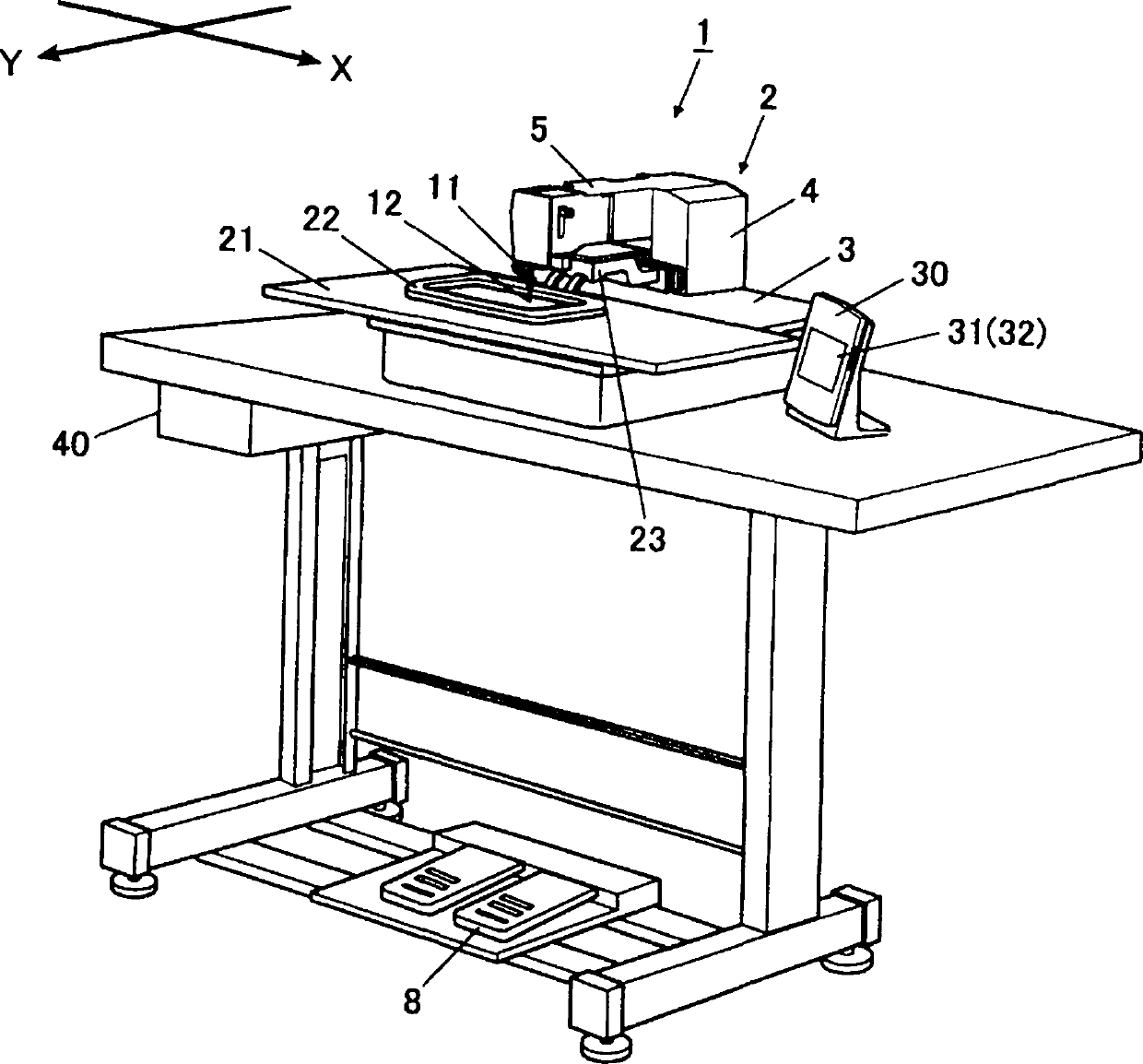

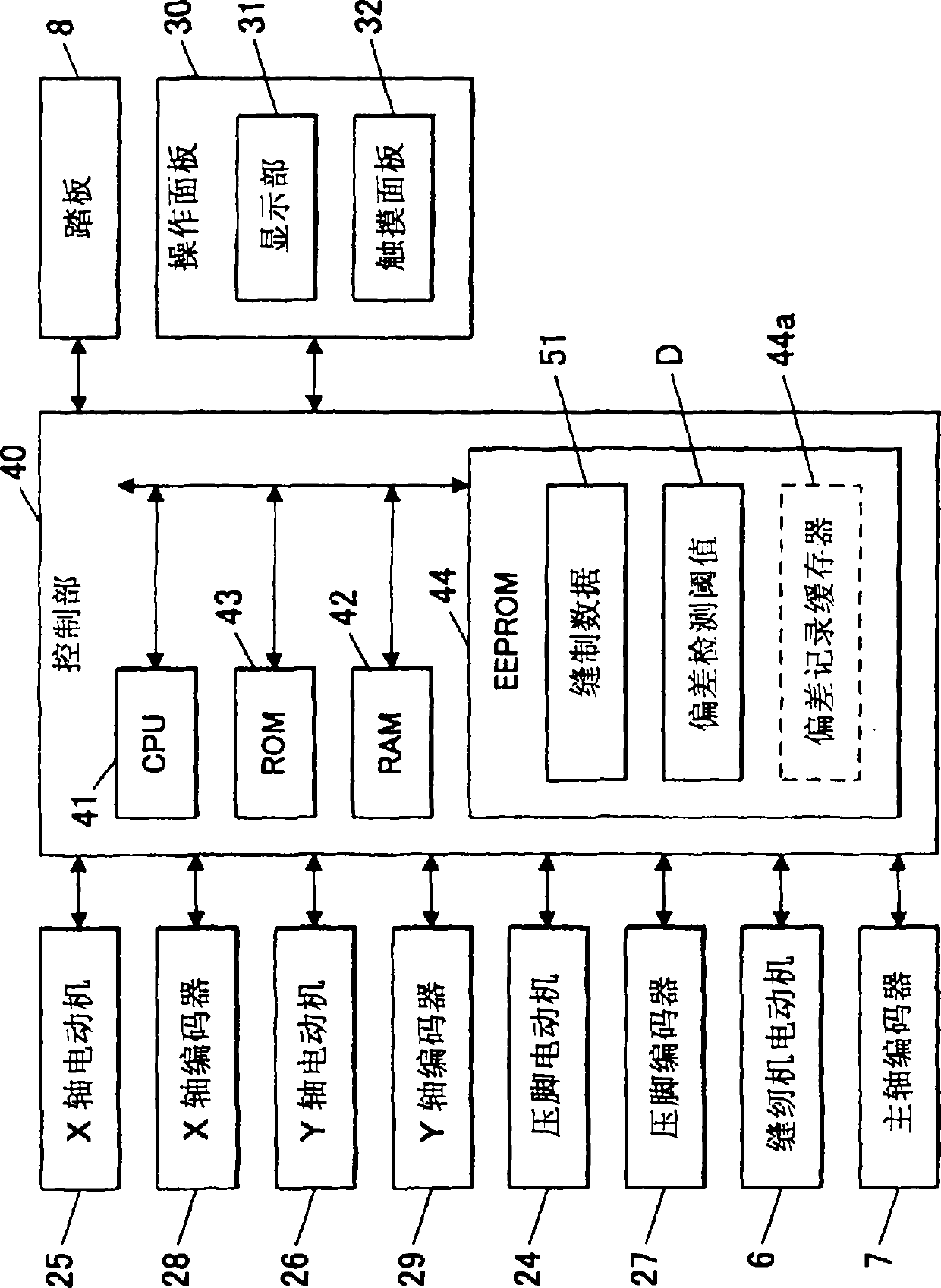

[0034] exist figure 1In the sewing machine 1 according to the present embodiment, the timing of the vertical movement of the needle bar 11 and the timing of the moving mechanism 20 moving the sewing product are controlled according to the sewing data 51 to form stitches. In the following description, the X-axis direction and the Y-axis direction perpendicular to each other are provided along a horizontal plane perpendicular to the vertical movement direction of the needle bar 11, and the plane is referred to as an X-Y plane.

[0035] The sewing machine 1 has: a sewing machine frame 2; a needle bar 11, which holds a sewing needle 12 and moves up and down; a moving mechanism 20, which holds a sewing object, and performs a feeding operation to move it along an X-Y plane; an operation panel 30,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com