Portal crane lock

A door machine lock and lock body technology, applied in the field of door machine locks, can solve problems such as restricting the development of subway platform safety doors, complex structure of door machine locks, difficult procurement, etc., and achieve the effects of compact structure, fewer parts and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

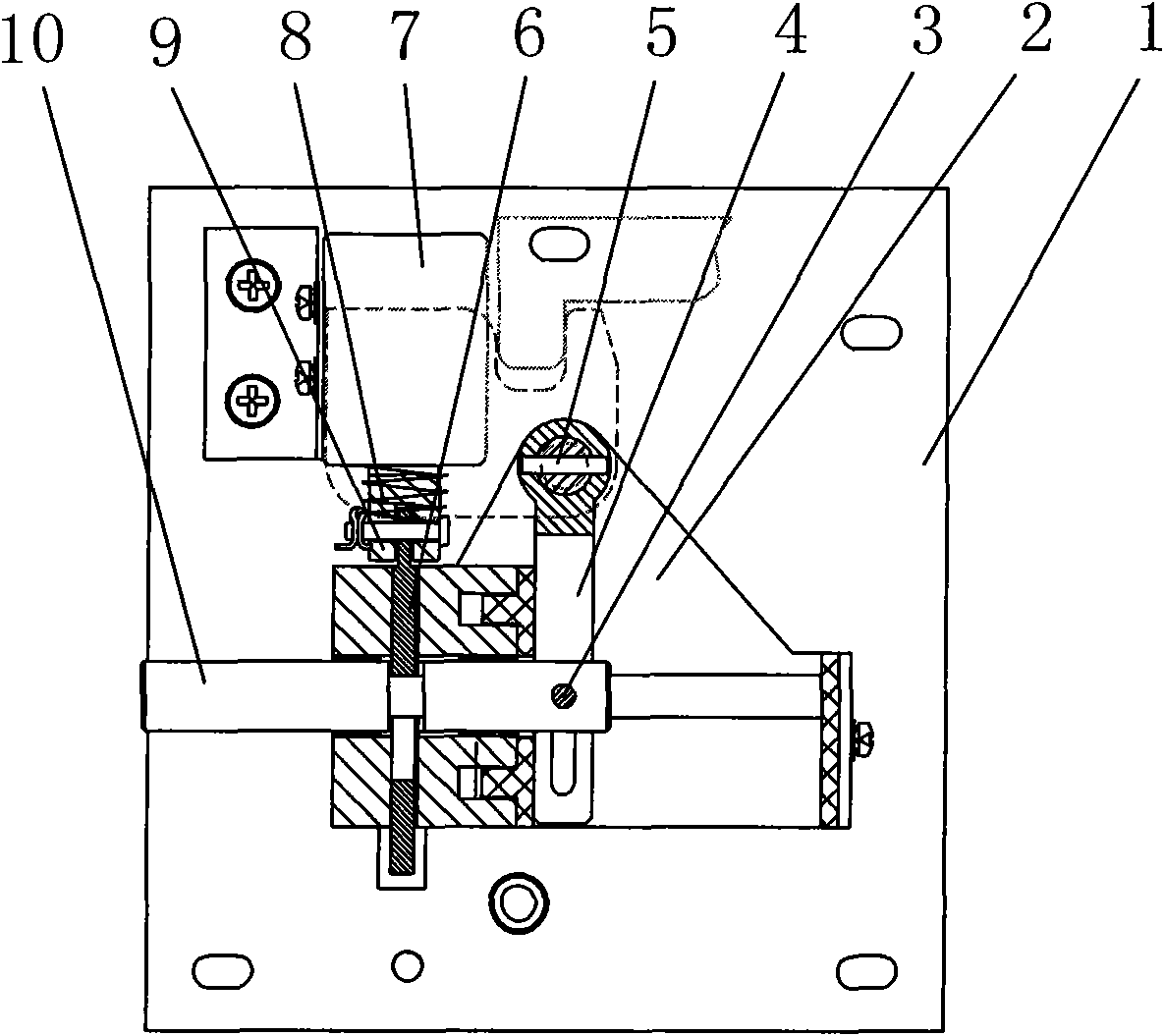

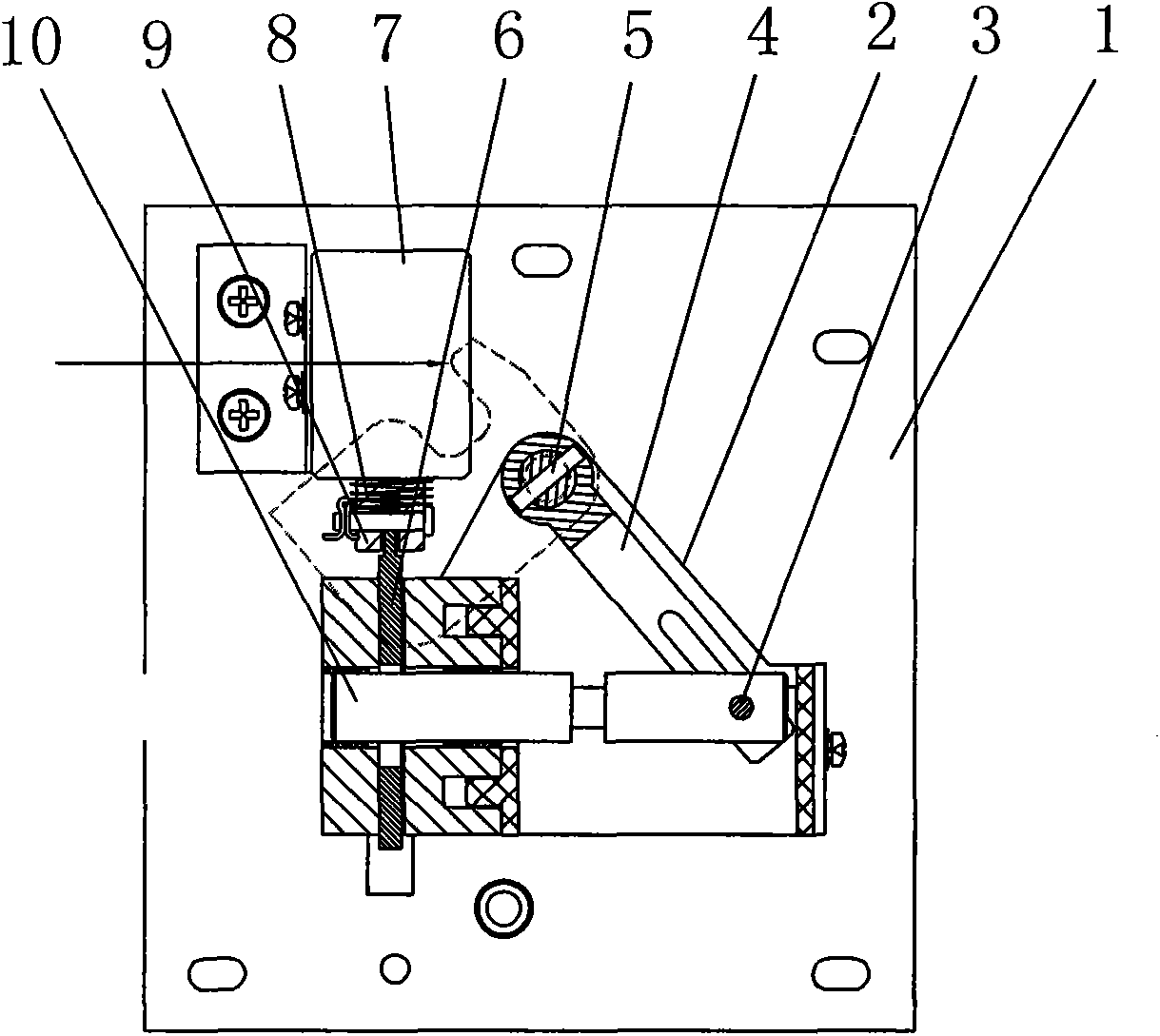

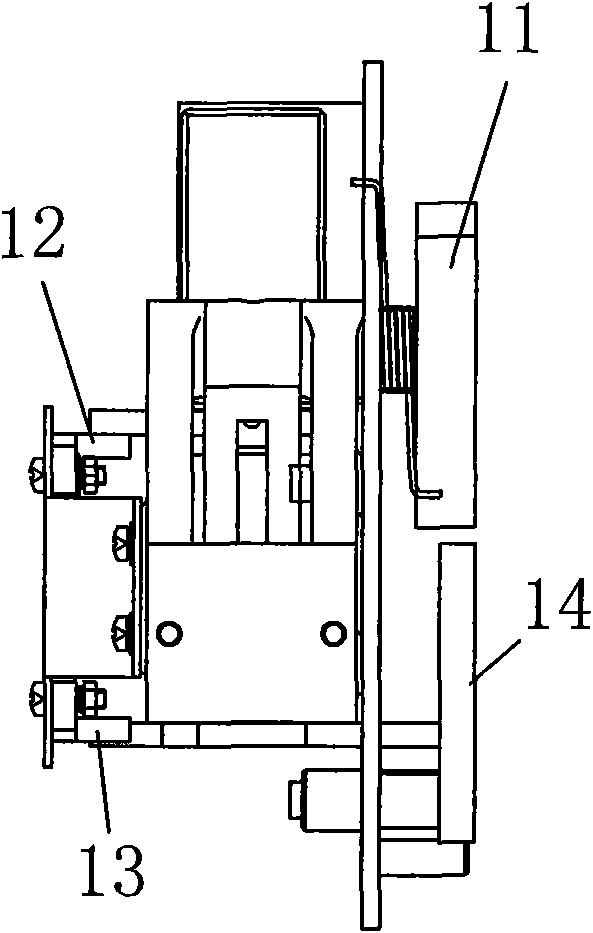

[0014] like figure 1 As shown, the door machine lock designed by the present invention includes: a lock body 2 fixed on the mounting plate 1; a lock plate 6 which is arranged in the lock body and can move up and down, and one end of the lock plate is connected with the lock plate to move the lock plate up and down. A moving rod 10 that penetrates the lock body and can slide left and right, the moving rod is provided with a slot 12 for the lock plate to enter, and one end of the moving rod is provided with a pin shaft hole, through the shaft pin 3 It is hinged with the waist-shaped hole provided on the swing rod 4; a rotating hook 11 located on one side of the lock body and connected by the support hole of the lock body, the support shaft on the rotating hook 11 is connected with the swing rod 4 through the pin shaft 5; it also includes the lock body There are two photoelectric travel switches 12 and 13 for sensing the moving position of the lock plate, which are arranged verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com