Reciprocating high-efficiency vortex fluid magnetizer

A fluid magnetizer, reciprocating technology, applied in the direction of machines/engines, internal combustion piston engines, engine components, etc., can solve the problem of no fuel-saving effect, achieve enhanced magnetic field strength and magnetization effect, prolong magnetization and magnetization time, prolong Effect of Magnetization Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

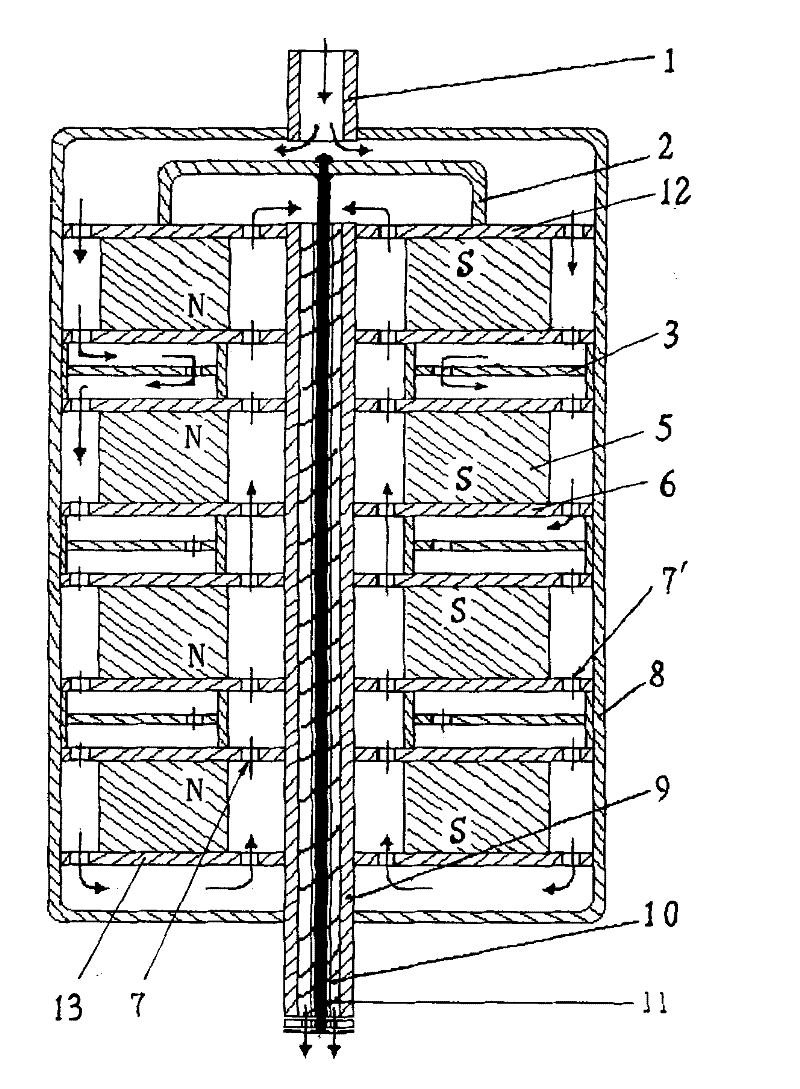

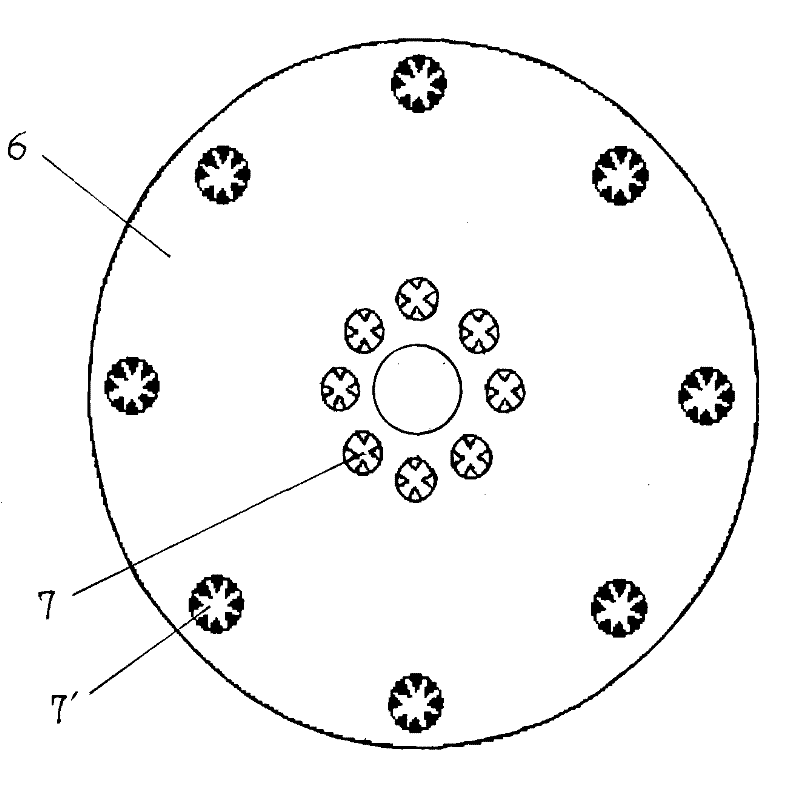

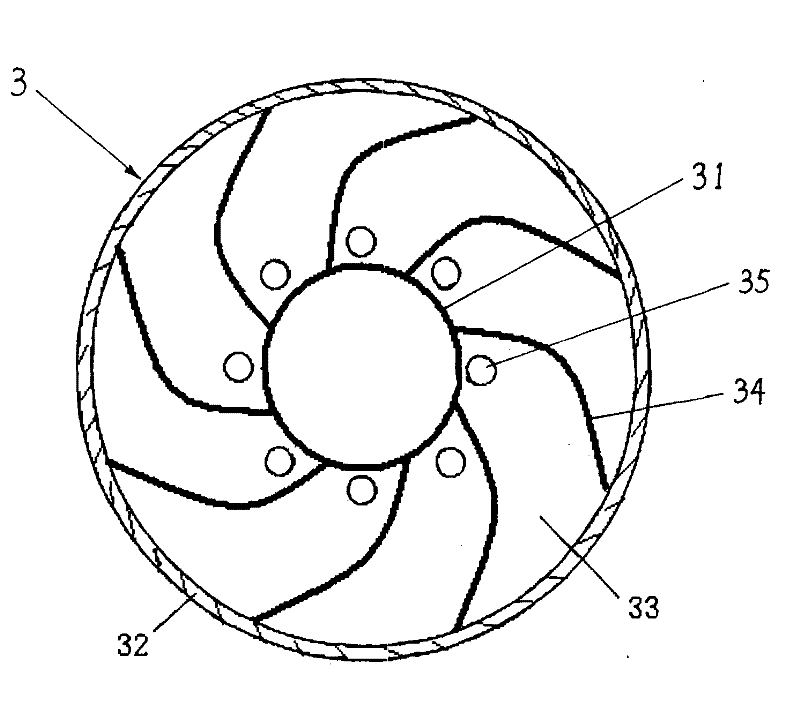

[0027] Such as figure 1 As shown, the housing 8 is in the shape of a cylinder made of a non-magnetic material, and the butt joints can be screwed together as required, or closed and welded. The liquid inlet pipe 1 is connected to the center of the top surface of the housing 8 . Four ring magnets 5 (which can be increased by 2) are arranged in the housing 8 . The upper and lower positions of the ring magnets 5 are relatively overlapped, and the magnetic ring planes of the same polarity are opposite to each other. Considering the problem of installation space, the volume of the magnetizer should not be too large, and generally 4 or 6 ring magnets are suitable. A magnetic short-circuit piece 6 is respectively arranged on the magnetic ring plane of the ring magnet, and an upper positioning piece 12 and a lower positioning piece 13 are respectively arranged on the top surface of the upper layer ring magnet and the bottom surface of the lower layer ring magnet. The magnetic short ...

Embodiment 2

[0035] This embodiment is a magnetizer with double magnetizer structure. Such as Figure 5 As shown, two parallel magnetized bodies are housed in a housing 8 with an approximately elliptical cross section, and each magnetized body is composed of a ring magnet 5, a magnetic short circuit 6, an isolation deflector 3, and a current guide as described in the above example. Pipe 9, isolation cover 2, upper positioning piece 12 and lower positioning piece 13 etc. are connected and formed. A mediastinum 19 separating the two magnetized bodies is provided between the two magnetized bodies, and the upper positioning piece 12 and the lower positioning piece 13 of the two magnetized bodies are respectively fixedly connected to the mediastinum plate 19 . The isolation cover 2 in each magnetized body is arranged on the upper positioning piece 12 , and the top surface of each isolation cover 2 is provided with a support block 27 fixedly connected with the top surface of the housing 8 . Th...

Embodiment 3

[0038] This embodiment is another magnetizer with double magnetizer structure. Such as Figure 6 As shown, the housing 8 is also a cylindrical structure with an approximately elliptical cross section, and two parallel magnetized bodies are housed in the housing 8, and each magnetized body is composed of a ring magnet 5, a magnetic short circuit piece 6, an isolation guide Device 3, guide pipe 9 and isolation cover 2 etc. are connected by the structural mode in embodiment 1 and form. In this embodiment, the two magnetized bodies share an upper positioning piece 12 and a lower positioning piece 13, and the two isolation covers 2 are all arranged on the upper positioning piece 12, and a medial septum 19 is arranged between the two magnetized bodies. The two magnetized bodies are isolated from each other.

[0039] Figure 6 Among them, the left side in the housing 8 is the first magnetized body, and the right side is the second magnetized body. The upper end of the guide tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com