Crawler crane super-lifting counterweight stepless luffing mechanism and its operation method

一种履带起重机、变幅机构的技术,应用在起重机等方向,能够解决工作效率低下、操作烦琐、费时等问题,达到拆卸和运输方便、结构简单、改善使用条件的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

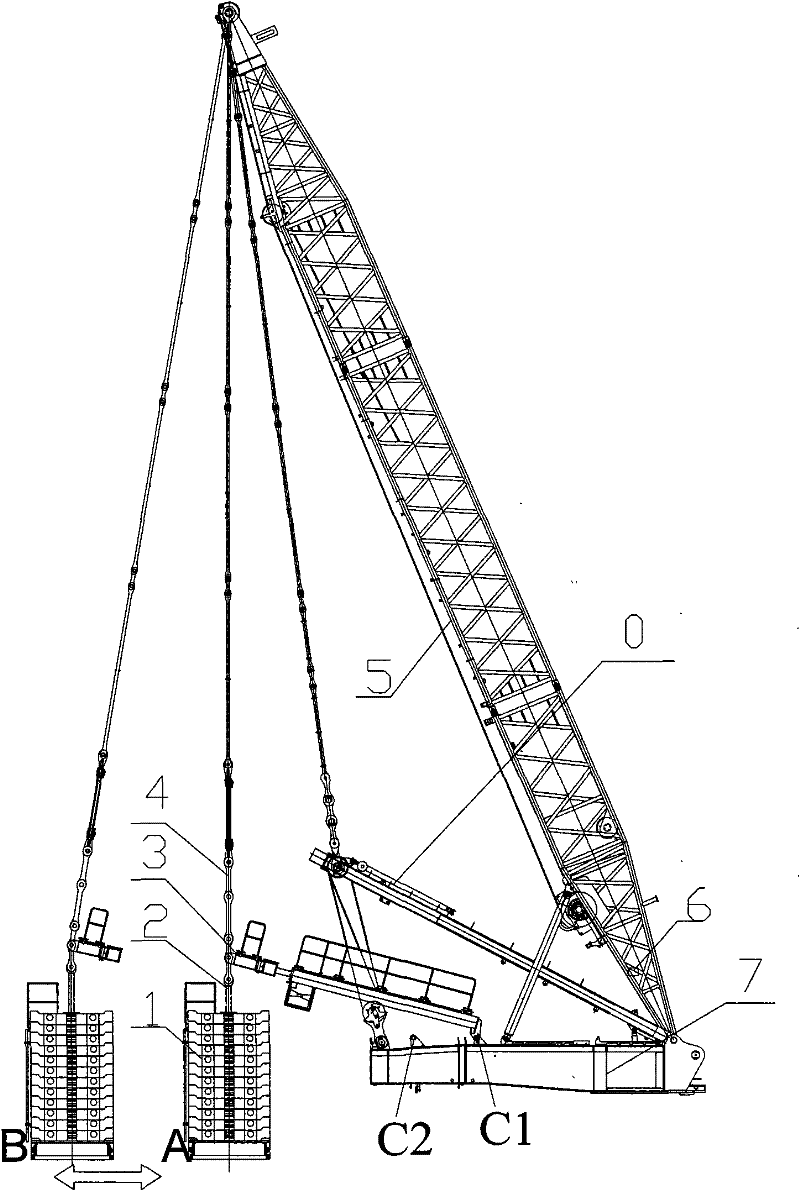

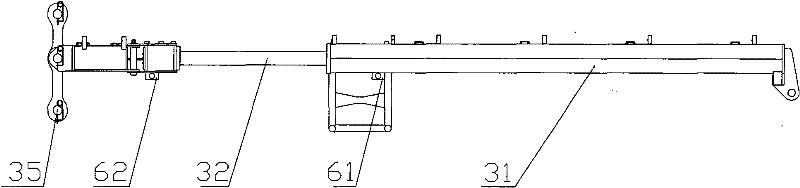

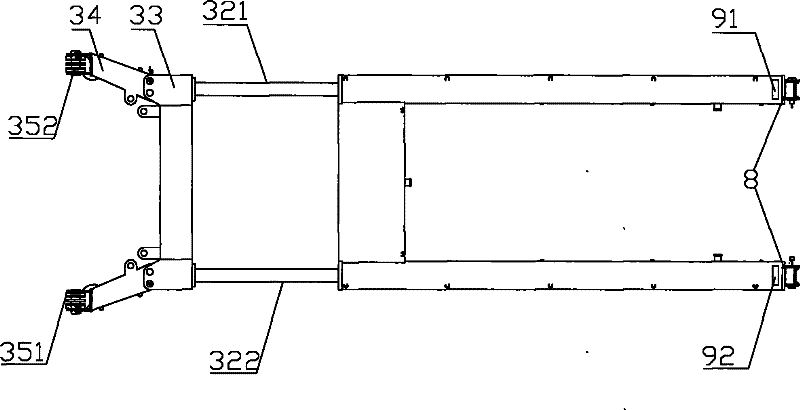

[0032] See figure 1 As shown, a crawler crane superlift counterweight stepless luffing mechanism includes a main luffing mast 0, a lifting cylinder 2, a superlift counterweight luffing structure 3, a superlift counterweight pull plate 4, a superlift mast 5 and The measurement sensor 6 installed under the superlift counterweight luffing structure 3 . The lower end of the lifting cylinder 2 is connected to the superlift counterweight 1, and the upper end is connected to the lower end of the front part of the superlift counterweight luffing structure 3; the upper end of the front part of the superlift counterweight luffing structure 3 is connected to the lower end of the superlift counterweight pull plate 4; The upper end of super lifting counterweight pull plate 4 links to each other with super lifting mast 5 by suspension rope, and the other end that sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com