Micro-adjusting mechanism

A technology of fine-tuning mechanism and left bracket, applied in the field of brackets, can solve problems affecting the quality of high-frequency heating treatment of steel pipe welds, fine-tuning, etc., and achieve the effects of improving the quality of medium-frequency heating treatment, accurate adjustment, and safe and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

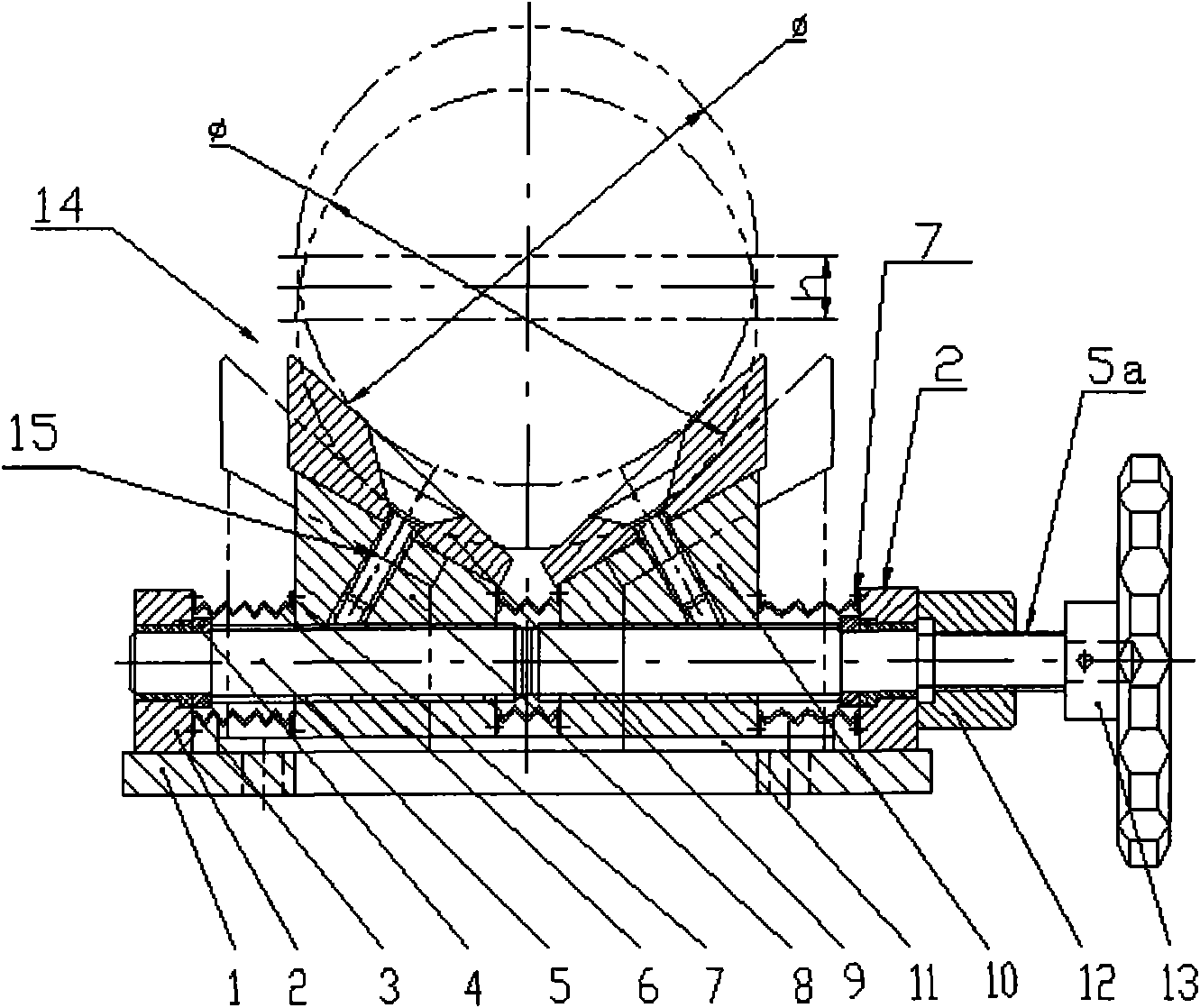

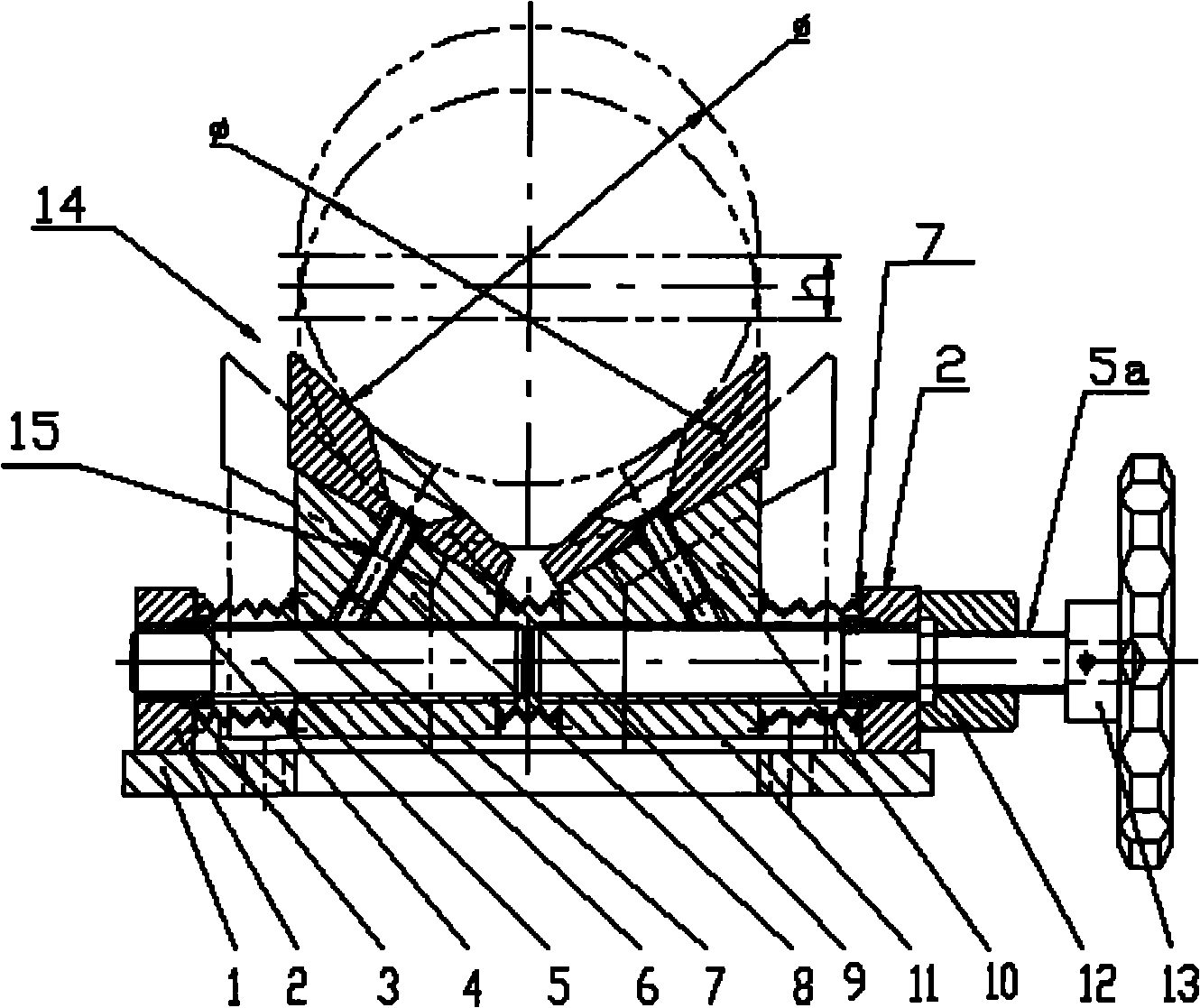

[0014] In the following, a fine adjustment mechanism of the present invention will be further described with reference to the drawings and specific embodiments.

[0015] As shown in FIG. 1, a fine adjustment mechanism of the present invention includes a mounting plate 1, a left bracket 8 and a right bracket 10 with an inclined surface (only shown in the figure, not marked), and the left bracket 8 and the right bracket on the inclined surface 10 constitutes a V-shaped bracket 14. The fine-tuning mechanism also has: a pair of supports 2, 2 respectively provided at both ends of the mounting plate 1 and provided with support holes (not shown); and a pair of supports 2 and 2 respectively supported in the support holes of the support 2 and provided with threads Two-way screws 5 that rotate in different two-way screw portions (not shown).

[0016] In addition, the two-way screw supported in the support hole of the support extends outward from any one of the support holes, and the operato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com