Horizontal adjusting mechanism for welding fixture

A technology of leveling and welding fixtures, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficulty in adjusting welding fixtures to the level, time-consuming and laborious installation of welding fixtures, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

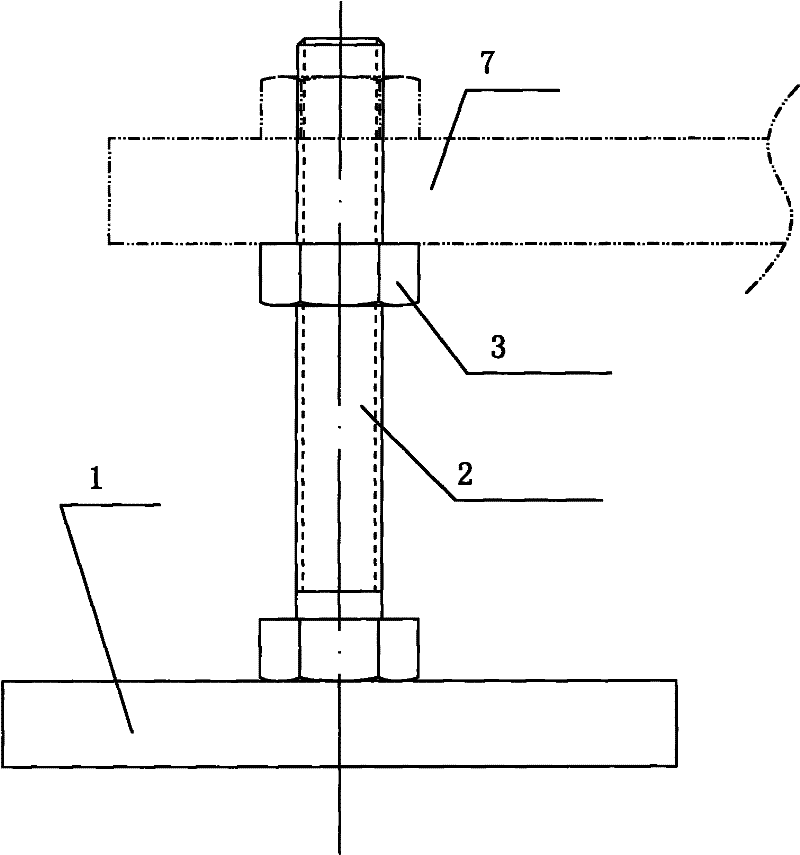

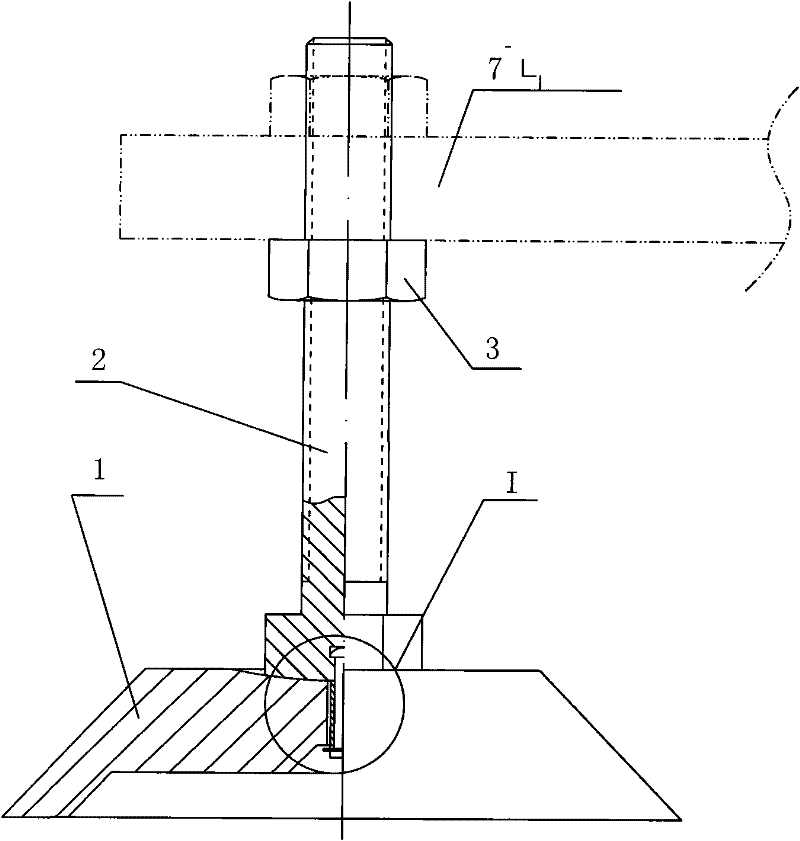

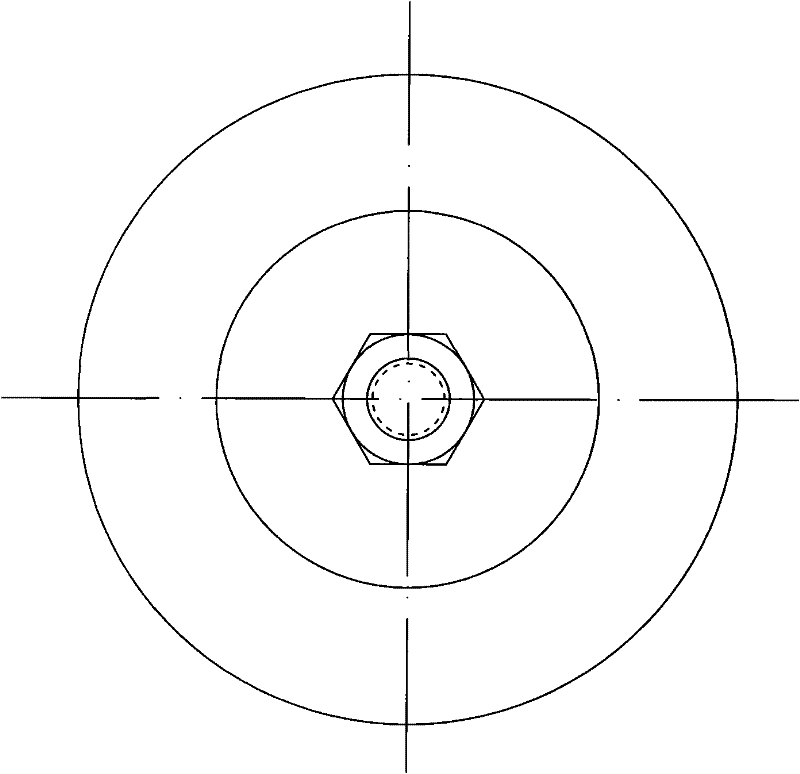

[0016] Combine below figure 2 , image 3 and Figure 4 Describe in detail the structure of the horizontal adjustment mechanism for this welding fixture:

[0017] The horizontal adjustment mechanism for the welding fixture includes a load-bearing pad 1, an adjustment bolt 2, a lock nut 3, a rivet 4, a connecting sleeve 5 and a washer 6. The adjusting bolt 2 is installed on the load-bearing pad 1, and the welding jig is clamped up and down by two lock nuts 3 and installed on the adjusting bolt 2.

[0018] The mutual assembly contact surfaces of the adjusting bolt 2 and the load-bearing pad 1 are all spherical contact surfaces, and the adjusting bolt 2 and the load-bearing pad 1 are connected by a rivet 4, and the rivet 4 penetrates upwards from the through hole at the bottom of the load-bearing pad 1 and connects with the bottom end of the adjusting bolt 2. Connecting hole connection, the rivet 4 is covered with a connecting sleeve 5, the connecting sleeve 5 is located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com