Rolling machine

A technology of coiling machine and winding motor, which is applied in the direction of coiling, thin material handling, transportation and packaging, etc. roll quality, and the effect of avoiding wrinkles on the surface of the cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

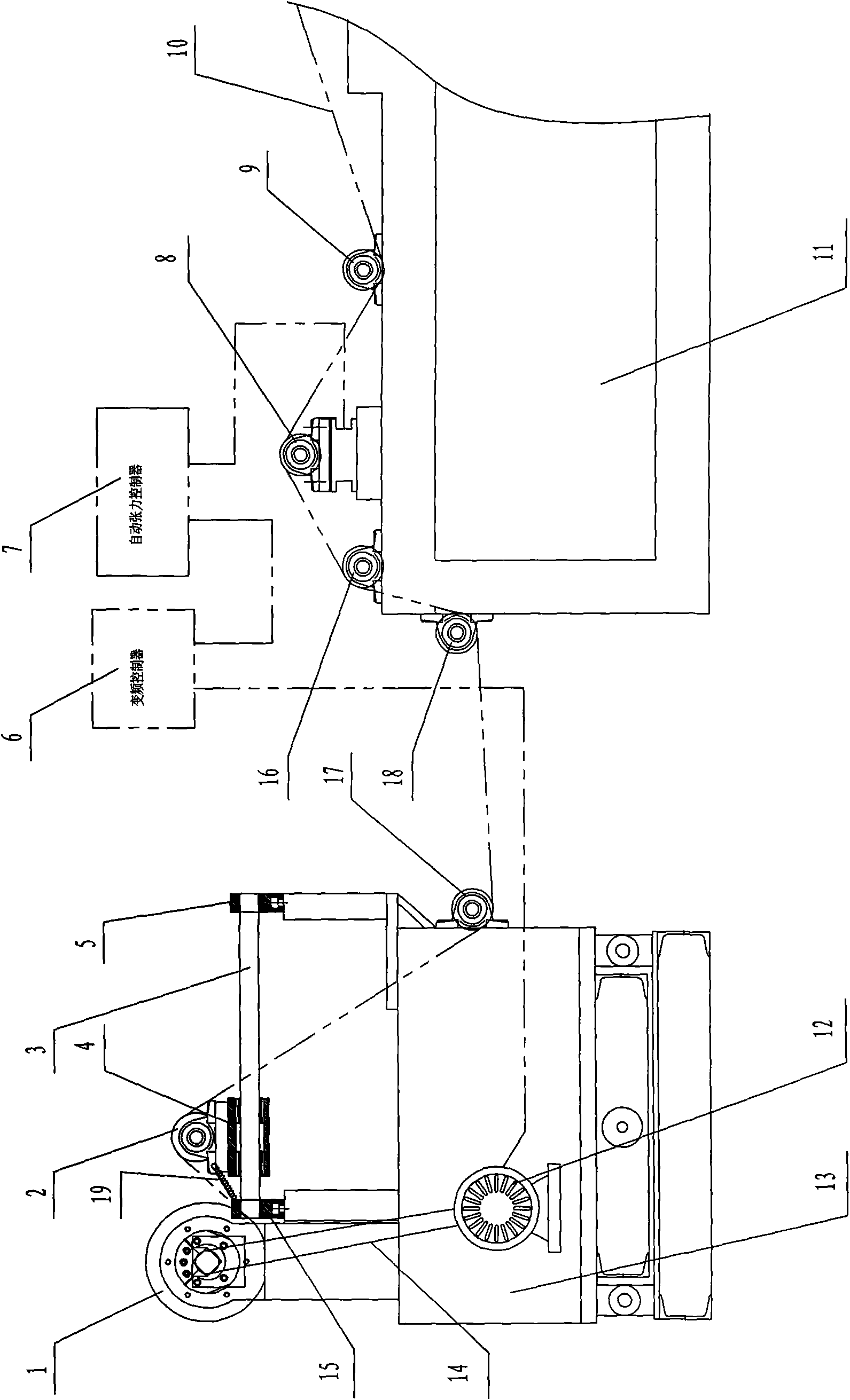

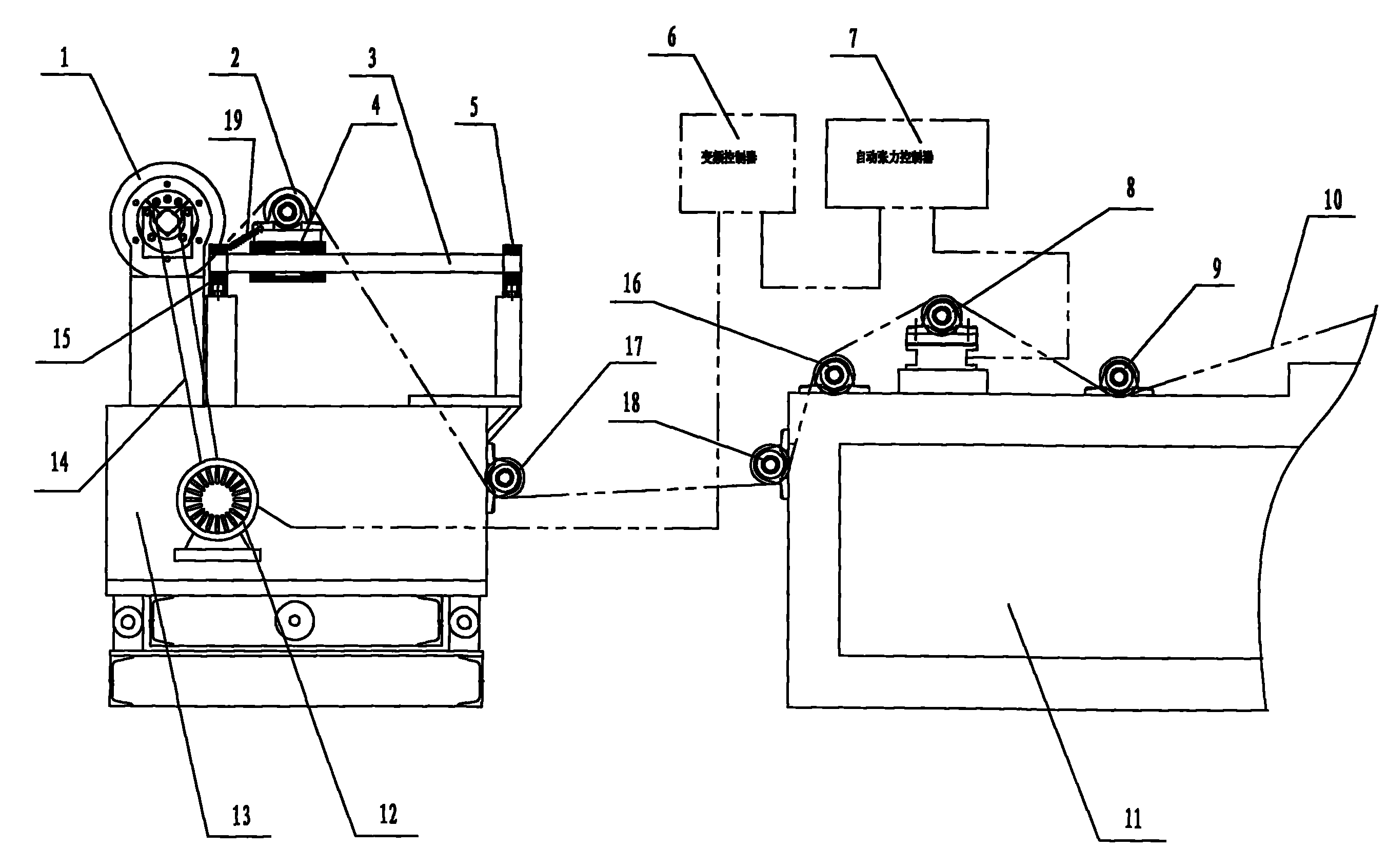

[0008] The coiler of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0009] As shown in the drawings, in this specific embodiment, the coiling machine of the present invention includes a frame 13, a winding air shaft 1, an expanding roller 2, an expanding roller bracket 4, a guide rail 3, a left guide rail bracket 15, a right Guide rail support 5, be connected on the frame 13 and be used for driving the rewinding motor 12 of rewinding inflatable shaft 1 rotation and the transmission device that is used to convey cloth 10, the two ends of rewinding inflatable shaft 1 are rotatably connected on machine On the frame 13, a transmission belt 14 is connected between the winding air expansion shaft 1 and the winding motor 12, and the expansion roller 2, the expansion roller support 4, the guide rail 3, the left guide rail support 15 and the right guide rail support 5 are all located on the winding air The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com