Method for preparing resin for latently-curable polyurethane ink

A resin for ink and latent curing technology, which is applied in the field of preparation of resin for polyurethane latent curing ink, can solve the problems of poor temperature resistance of ink, achieve the effects of improving adhesion fastness, ensuring storage life, and improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An embodiment of the present invention provides a method for preparing a polyurethane latent-curable ink resin, comprising:

[0028] Preparation of polyester diol:

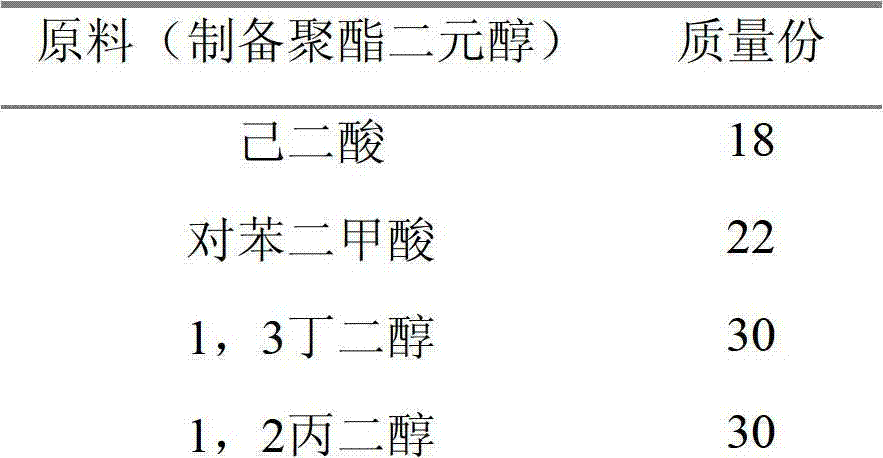

[0029] Get each raw material of preparing polyester diol by following mass percentage:

[0030] Adipic acid 15-25%, terephthalic acid 15-25%, 1,3 butanediol 25-35% and 1,2 propylene glycol 20-30%;

[0031] Add adipic acid, terephthalic acid, 1,3 butanediol and 1,2 propylene glycol into the polyester synthesis kettle, raise the temperature to 200-240°C for esterification reaction, and react for 5-6 hours; keep the polyester synthesis kettle The water yield is stable at 2-4% / hour of the total mass of the raw materials used to prepare the polyester diol.

[0032] After the esterification reaction is completed, you can also confirm whether the esterification reaction is qualified by measuring the acid value of the product. If the acid value of the measured product is ≦20mgKOH / g, it is confirmed that the ester...

Embodiment 2

[0053] The present embodiment 2 provides a kind of preparation method of resin for polyurethane latent curing type ink, specifically comprises:

[0054] (1) To prepare polyester diol, take the following table to prepare the raw materials for polyester diol:

[0055]

[0056] The method for preparing polyester diol is:

[0057] a. Add adipic acid, terephthalic acid, 1,3 butanediol, 30 and 1,2 propanediol into the polyester synthesis kettle, raise the temperature to 240°C, and react for 5 hours. After the esterification reaction is completed, measure the acid value: 18mgKOH / g;

[0058] b. Vacuum down the inside of the polyester synthesis kettle to -0.04Mpa, pay attention to observe the water output of the polyester synthesis kettle, keep the water output stable at 15kg / hour, and stop the low vacuum after 1.5 hours of low vacuum (can be cut off and The connected vacuum pipeline valve realizes stopping the low vacuum in the polyester synthesis kettle), and puts the distillate...

Embodiment 3

[0071] The present embodiment 3 provides a kind of preparation method of resin for polyurethane latent curing type ink, specifically comprises:

[0072] (1) To prepare polyester diol, take the following table to prepare the raw materials for polyester diol:

[0073]

[0074] The method for preparing polyester diol is substantially the same as in Example 2, see Example 2, and will not be repeated here.

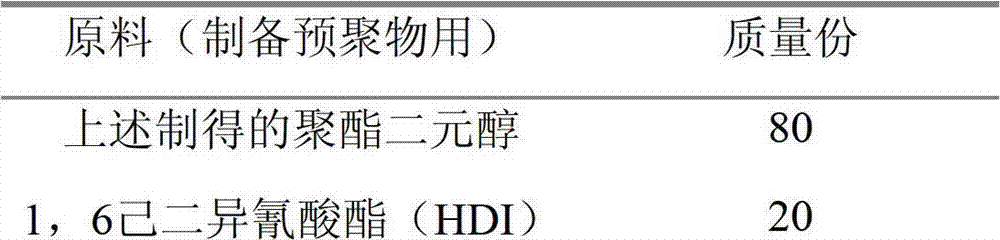

[0075] (2) Preparation of prepolymer:

[0076]

[0077] React the above-prepared polyester diol with isophorone diisocyanate (IPDI) at 110°C for 4 hours, and the obtained product is a prepolymer. The -NCO% content of the prepolymer is measured to be 6.9%;

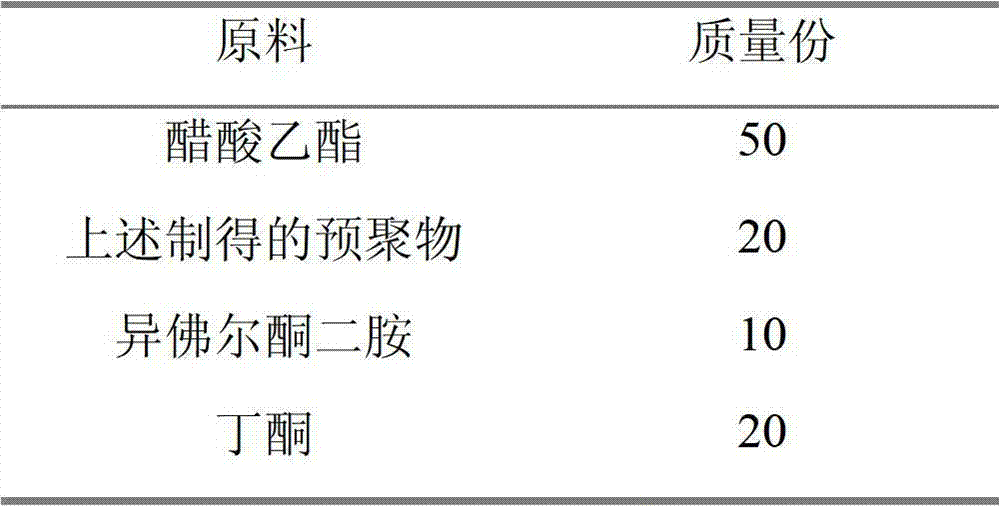

[0078] (3) Preparation of resin A:

[0079]

[0080] Add toluene to the above-prepared prepolymer, stir evenly, and gradually add ethylenediamine chain extender and butanone, the temperature of the mixed liquid is controlled at 80°C, and the product obtained after 2 hours of reaction is resin A. Test viscosity 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com