Nonorthogonal helical conical worm gear pair and nonorthogonal helical conical worm gear limited slip differential

A limited-slip differential, bevel gear technology, applied in gear transmission, differential transmission, belt/chain/gear, etc., can solve problems such as design and processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Specific implementation plan

[0020] The embodiments of the present invention will be described below based on the drawings.

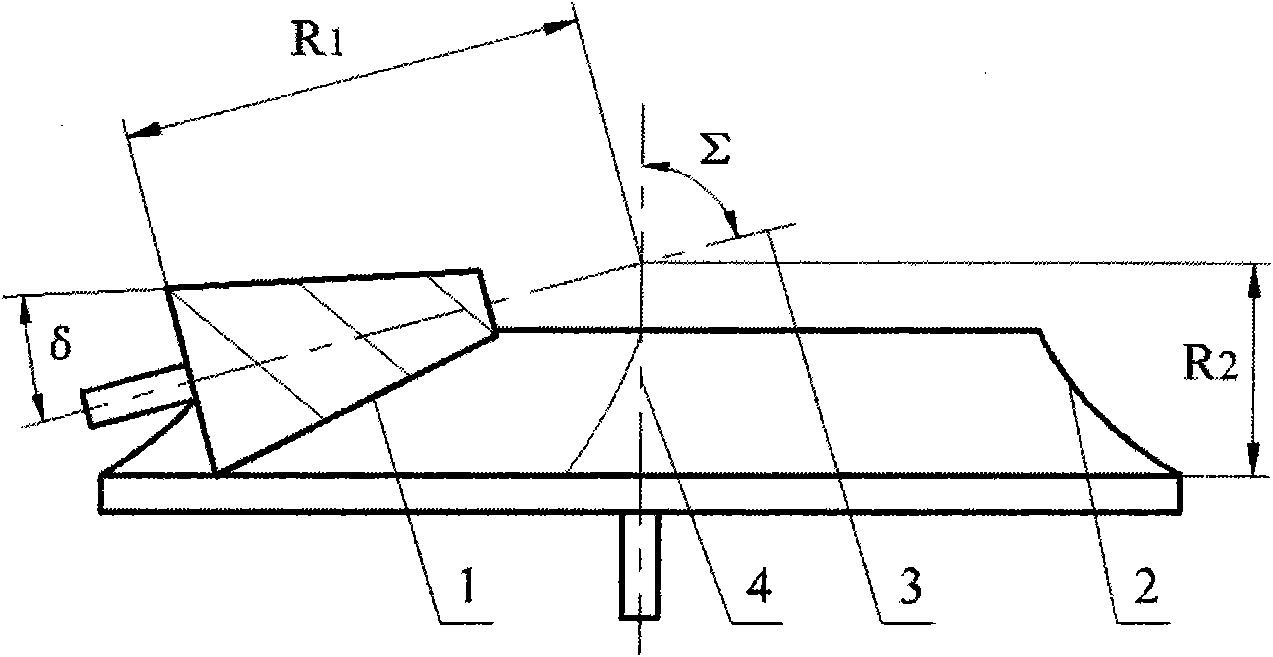

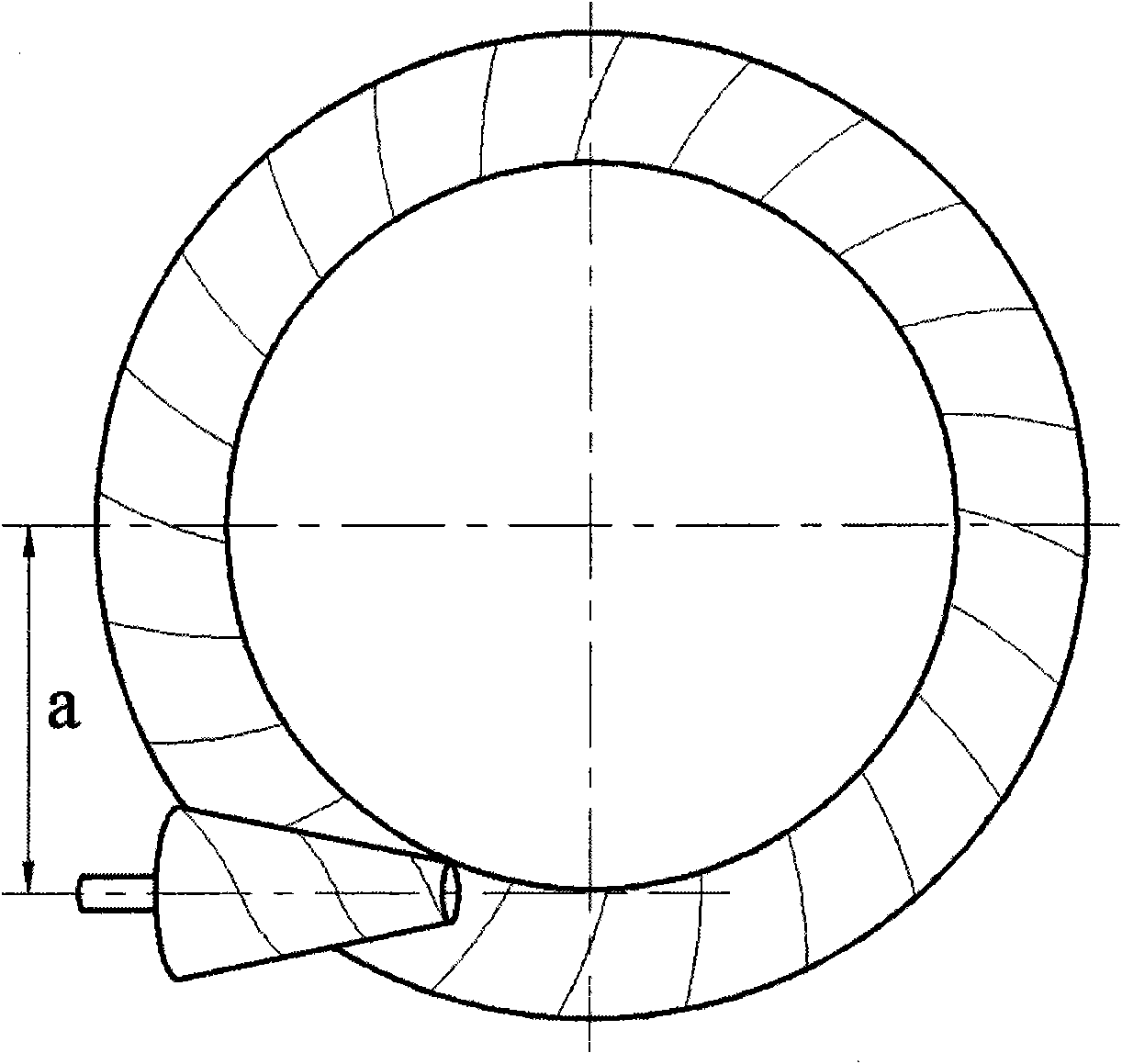

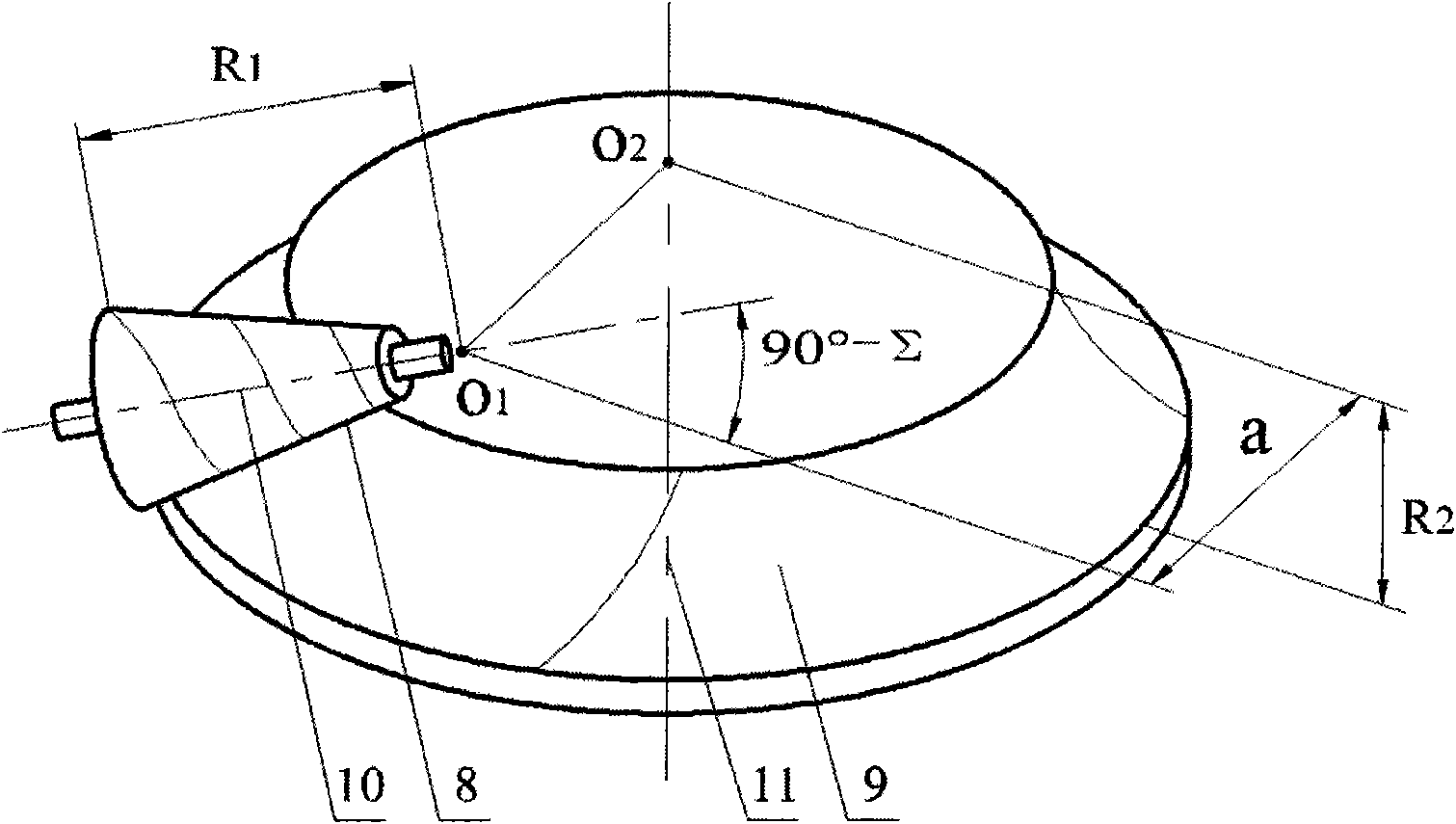

[0021] figure 1 The non-orthogonal helical bevel gear pair shown is composed of helical bevel gear 1 and large gear 2. The helical bevel gear axis 3 and the large gear axis 4 are spatially staggered, and the fixed included angle of the two axes is ∑, 01 , R 2 The helical bevel gear 1 and the large gear 2 that mesh with each other form a non-orthogonal helical bevel gear pair (such as figure 2 ); the number of teeth of helical bevel gear 1 z 1 , Helix angle β 1 , Cone angle δ, the number of teeth of the large gear 2 z 2 , By changing the number of teeth z of the helical bevel gear 1 1 Or helix angle β 1 And non-orthogonal helical bevel gear pair transmission ratio i 12 =z 2 / z 1 Or the shaft angle Σ can change the forward and reverse transmission efficiency of the non-orthogonal helical bevel gear pair. When the transmission efficiency η=0, the mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com