Ultrasonic humidifier and atomizing device thereof

A technology of atomization device and humidifier, which is applied to ultrasonic humidifier, spray device, liquid spray device, etc., can solve the problems of increased air humidity and small atomization amount, and achieves the improvement of atomization amount and indoor air humidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

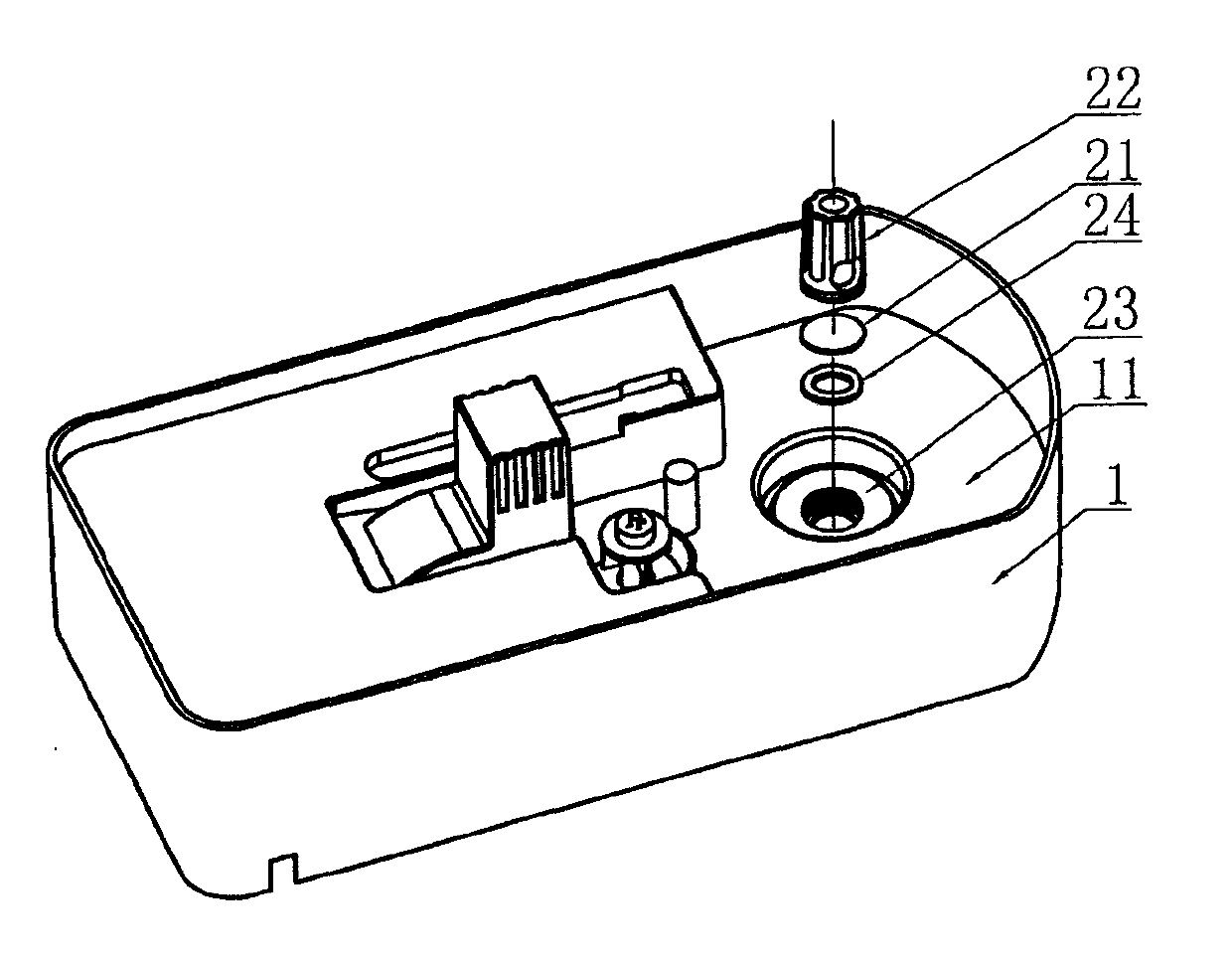

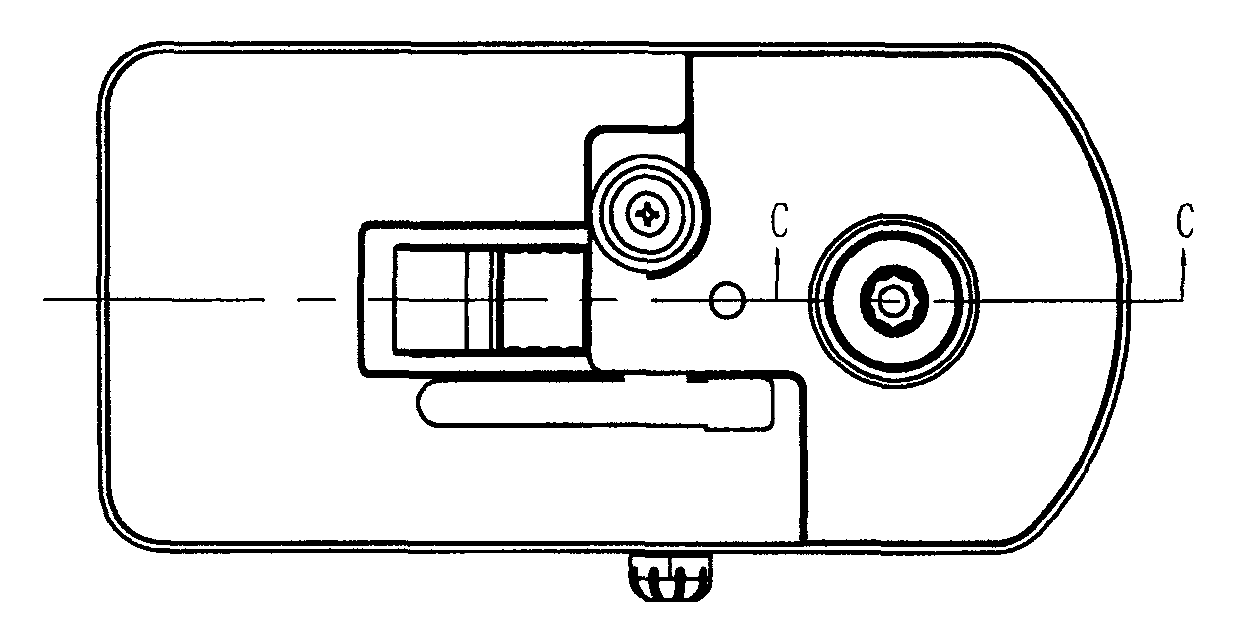

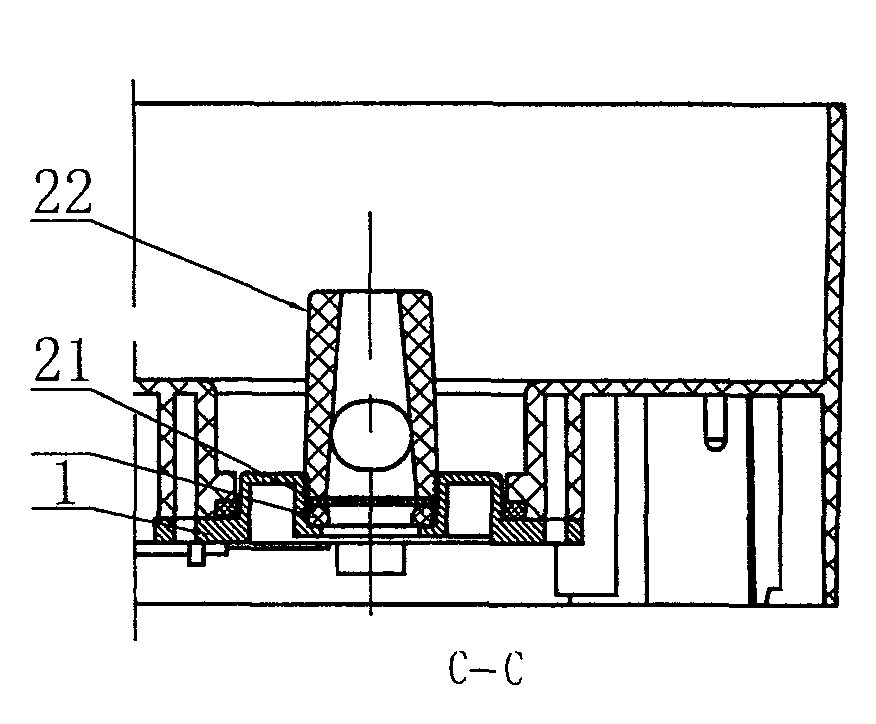

[0050] see Figures 1 to 6A As shown, the ultrasonic humidifier proposed by the embodiment of the present invention includes a machine base 1 and a water tank assembly, the water tank assembly is connected above the machine base, and the top of the machine base 1 has a water tank 11 . Described ultrasonic humidifier comprises atomizing device 2, and atomizing device 2 comprises transducer 21 (also known as oscillator) and can improve the energy-gathering cover 22 of atomization amount, and energy-gathering cover 22 is arranged on the front of transducer 21 Above, the transducer 21 is set on the machine base 1 and located in the water tank 11 ; the energy gathering cover 22 is set on the machine base 1 or the water tank assembly, and the energy gathering cover 22 of this embodiment is set on the machine base 1 .

[0051]When the embodiment of the present invention is in use, first add enough water to the water tank assembly, and after the water tank assembly is connected to the...

Embodiment approach 2

[0058] see Figure 7 to Figure 12A As shown, the basic structure, working principle and beneficial effect of the ultrasonic humidifier in the embodiment of the present invention are basically the same as those in Embodiment 1, the difference is that the energy-gathering cover 22' in the embodiment of the present invention is not installed on the core to dissipate heat chip, but mounted on chassis 1.

[0059] Specifically, a through-hole 221' is provided in the axial direction of the energy-gathering cover 22', and at least one water inlet 222' is provided at the bottom of the energy-gathering cover 22', and the water inlet 222' communicates with the through-hole 221'. Preferably, the energy gathering cover 22' is tapered, the through hole 221' is a tapered hole, the diameter of the lower end of the through hole 221' is larger than the diameter of the upper end, and the diameter of the lower end of the through hole 221' corresponds to the diameter of the transducer 21' .

[0...

Embodiment approach 3

[0065] see Figure 13 with Figure 13A As shown, the basic structure, working principle and beneficial effect of the ultrasonic humidifier in the embodiment of the present invention are basically the same as those in Embodiment 2, the difference is that the support member of the energy gathering cover 22' in the embodiment of the present invention is fixedly connected to On the machine base 1, it forms an integral structure with the machine base 1 and cannot be disassembled.

[0066] The same parts in the embodiment of the present invention as in Embodiment 2 will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com