Anti-tripping reverse buckling device

A technology of undercut and inner joint, which is applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of unusable, restricted use of reversed joints, and the tripping of reversed joints and falling into the well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

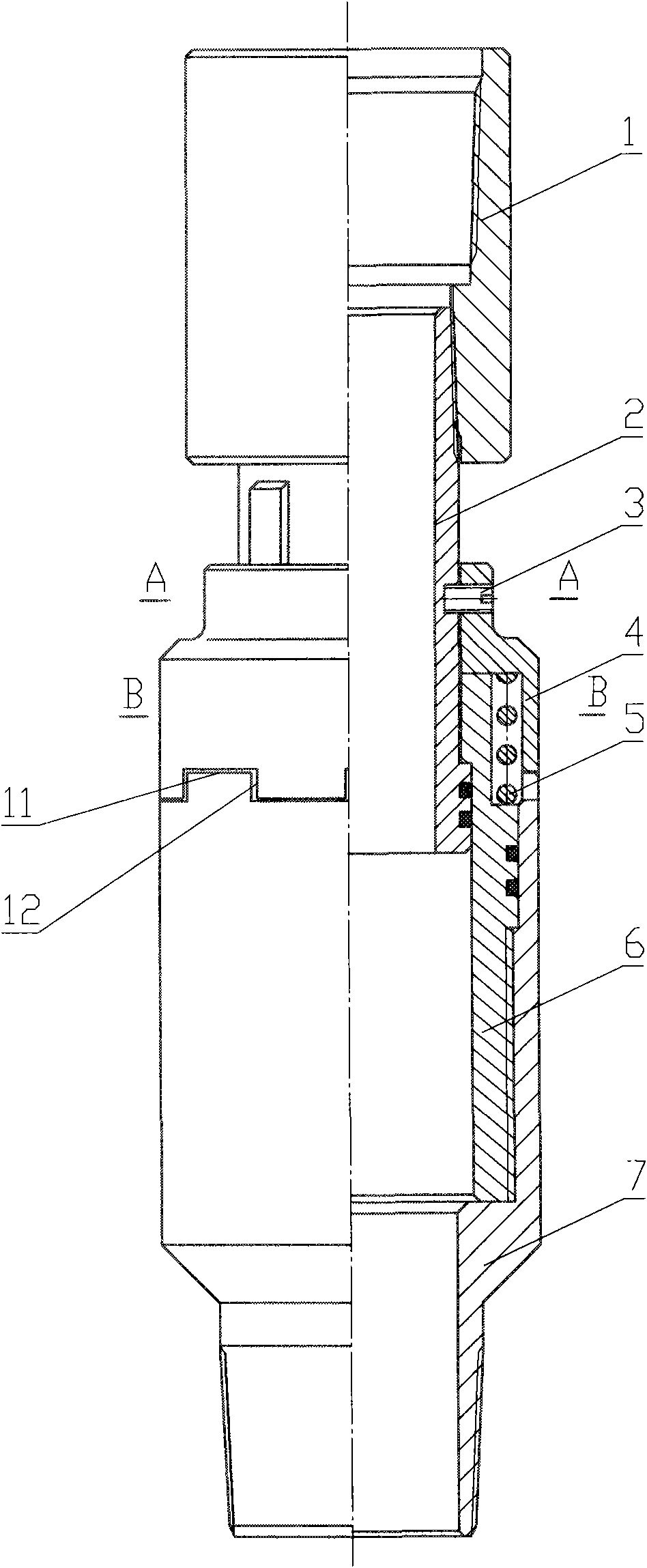

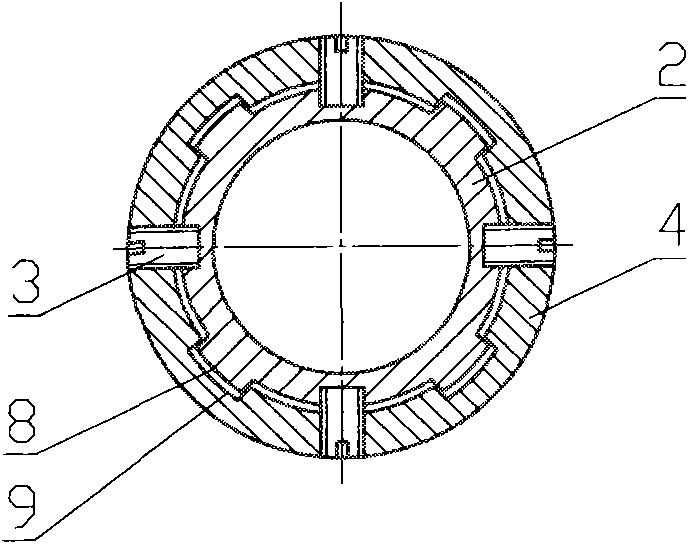

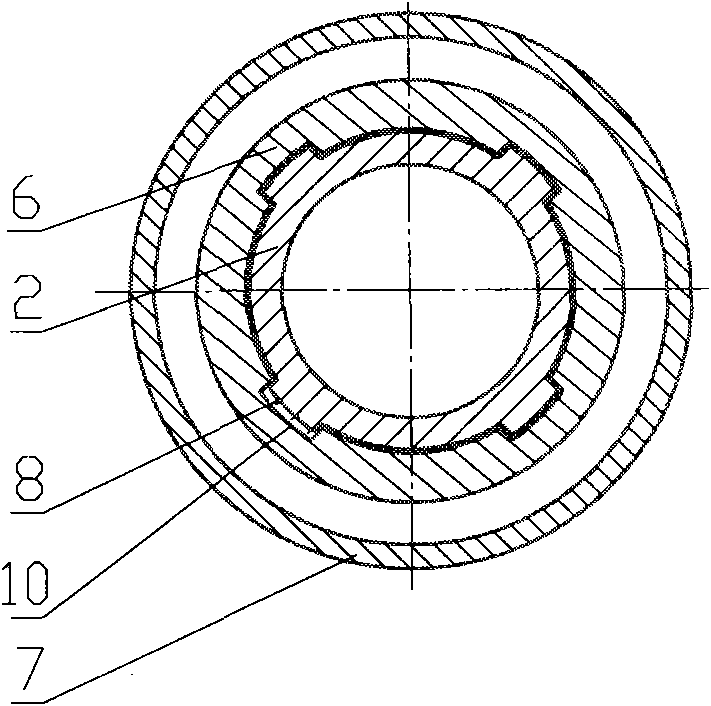

[0009] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0010] The embodiment of the present invention is composed of oil pipe collar 1, upper joint 2, shear pin 3, lock sleeve 4, spring 5, reverse buckle inner joint 6, reverse buckle outer joint 7, oil pipe collar 1 is connected with upper joint 2, reversely The inner shoulder of the buckle inner joint 6 is suspended on the outer shoulder of the upper joint 2, the lower part of the buckle inner joint 6 is connected with the buckle inner thread of the buckle outer joint 7, and the upper part of the lock sleeve 4 is set on the upper joint 2, there is a convex key 8 on the upper joint 2, and a lock key groove 9 is provided in the lock sleeve 4, and the convex key 8 is inserted in the lock key groove 9, and the lock sleeve 4 is fixed on the upper joint 2 by the shear pin 3, and the inner joint 6 is reversely buckled. There is a positive keyway 10 inside the upper part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com