Semi-automatic repeating crossbow

A semi-automatic crossbow string technology, applied in the field of bow and arrow crossbows, can solve the problems of inconvenient refueling, difficulty in realizing automatic reloading and continuous firing, inconvenient folding, etc., and achieve the goal of not easy to lose, convenient for storage and transportation, and fast and convenient for refueling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

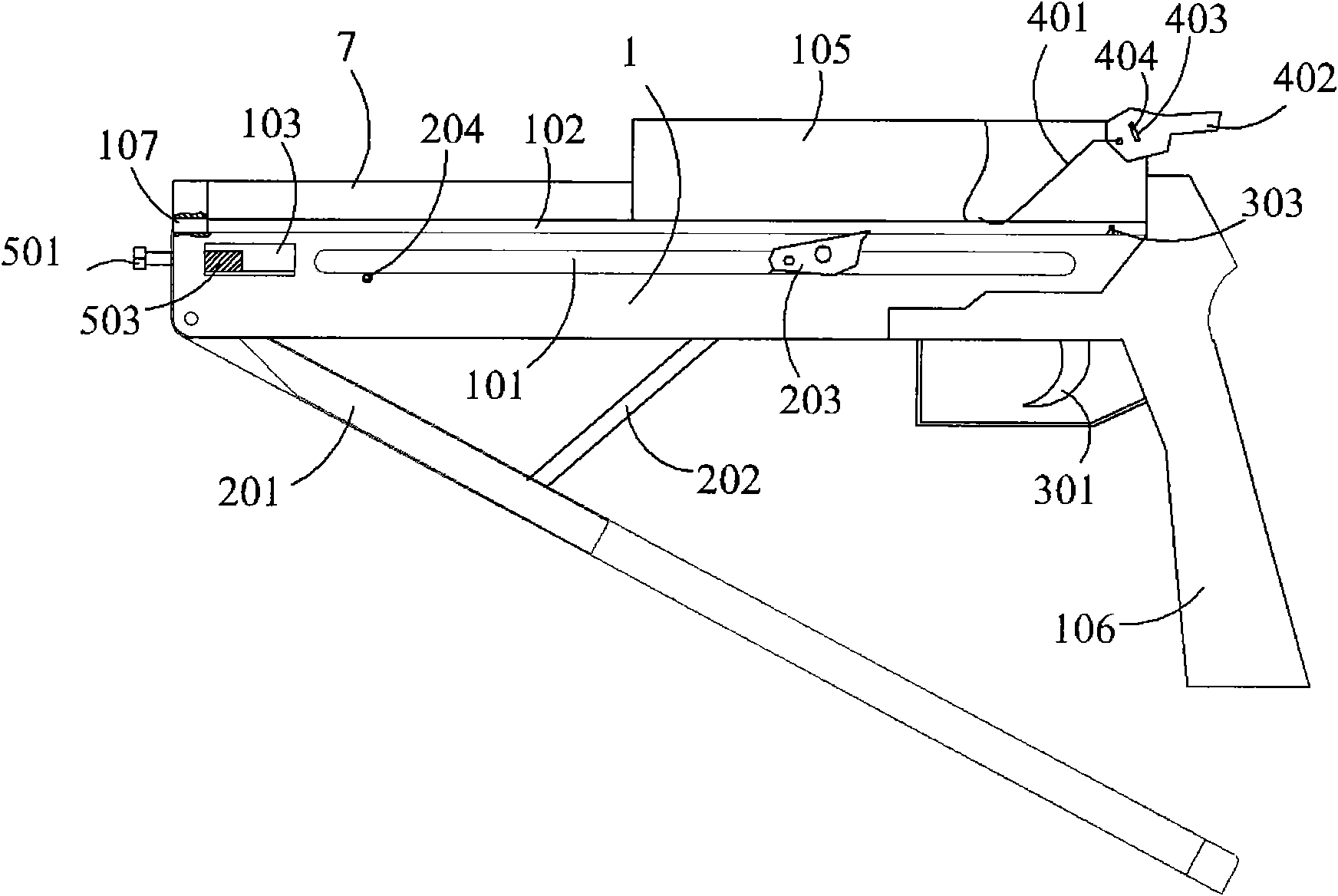

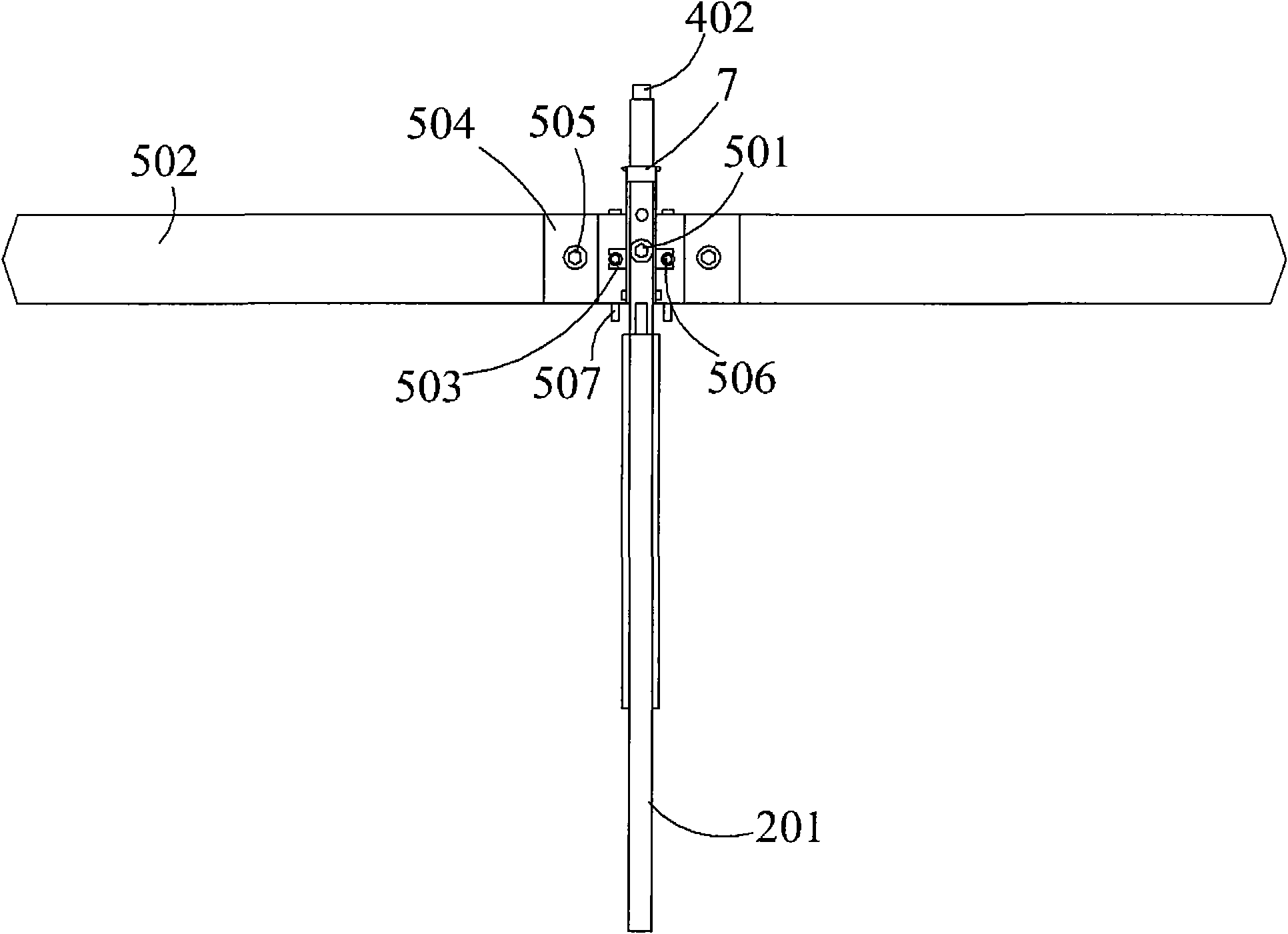

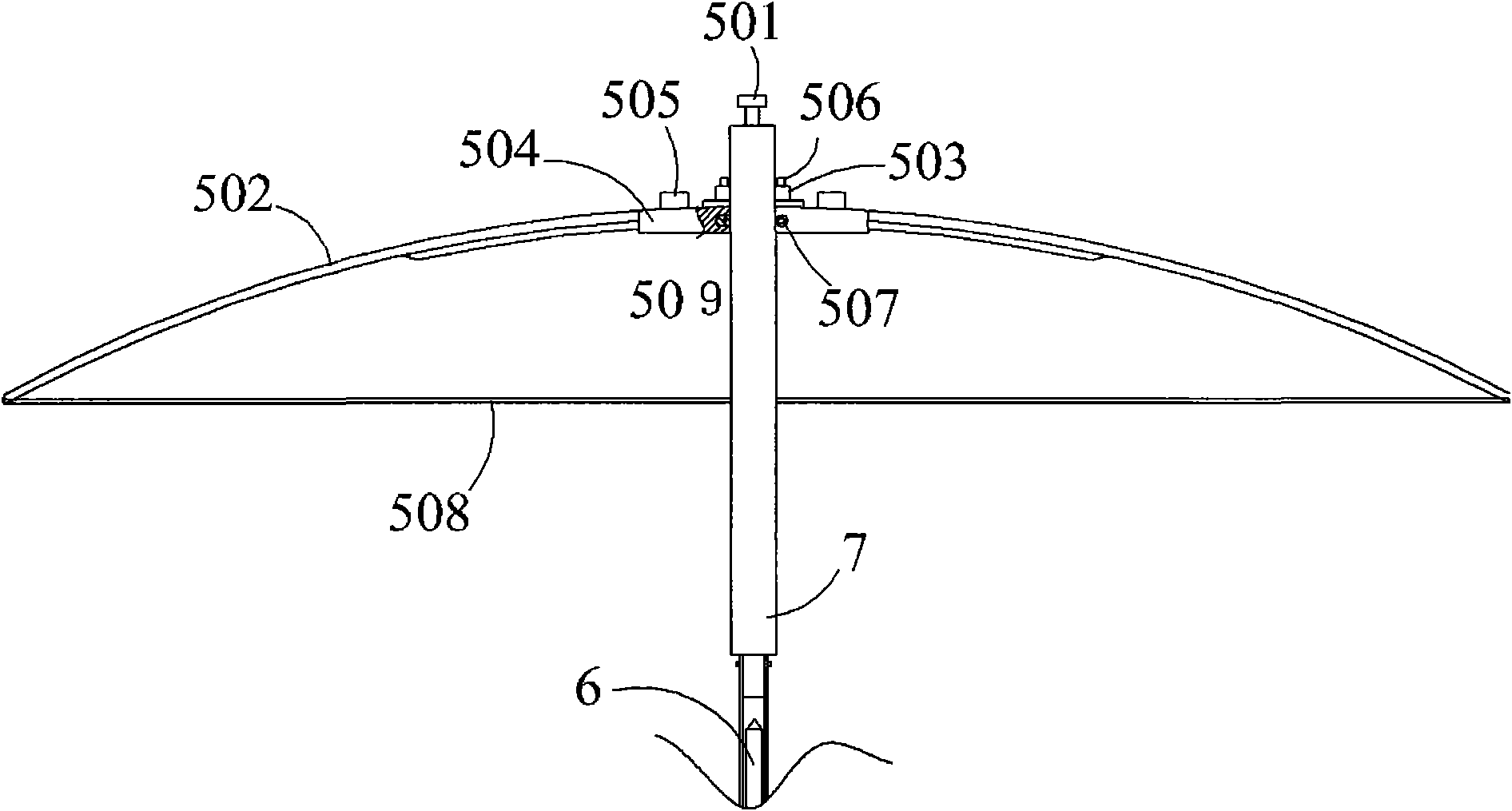

[0041] see figure 1 As shown, it is the front view of the inserted force storage mechanism of the semi-automatic repeating crossbow of the present invention, which includes: a crossbow frame 1, which constitutes the main structure of the semi-automatic repeating crossbow of the present invention, and other structures are related to it. Combined to form the functions of the present invention; a power storage mechanism, which has a pair of support arms 502, the support arms are located on the two wings of the crossbow frame 1, the crossbow strings 508 and the two ends of the support arms 502 Fixedly connected, the support arm 502 is realized to form a folded shape relative to the crossbow frame 1 through a folding mechanism (combined with image 3 shown); a force-enhancing mechanism, which is used to make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com