Lens array, lens unit, LED head, exposing unit, image forming apparatus, and image reading apparatus

A technology of lens array and lens unit, applied in the field of lens array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

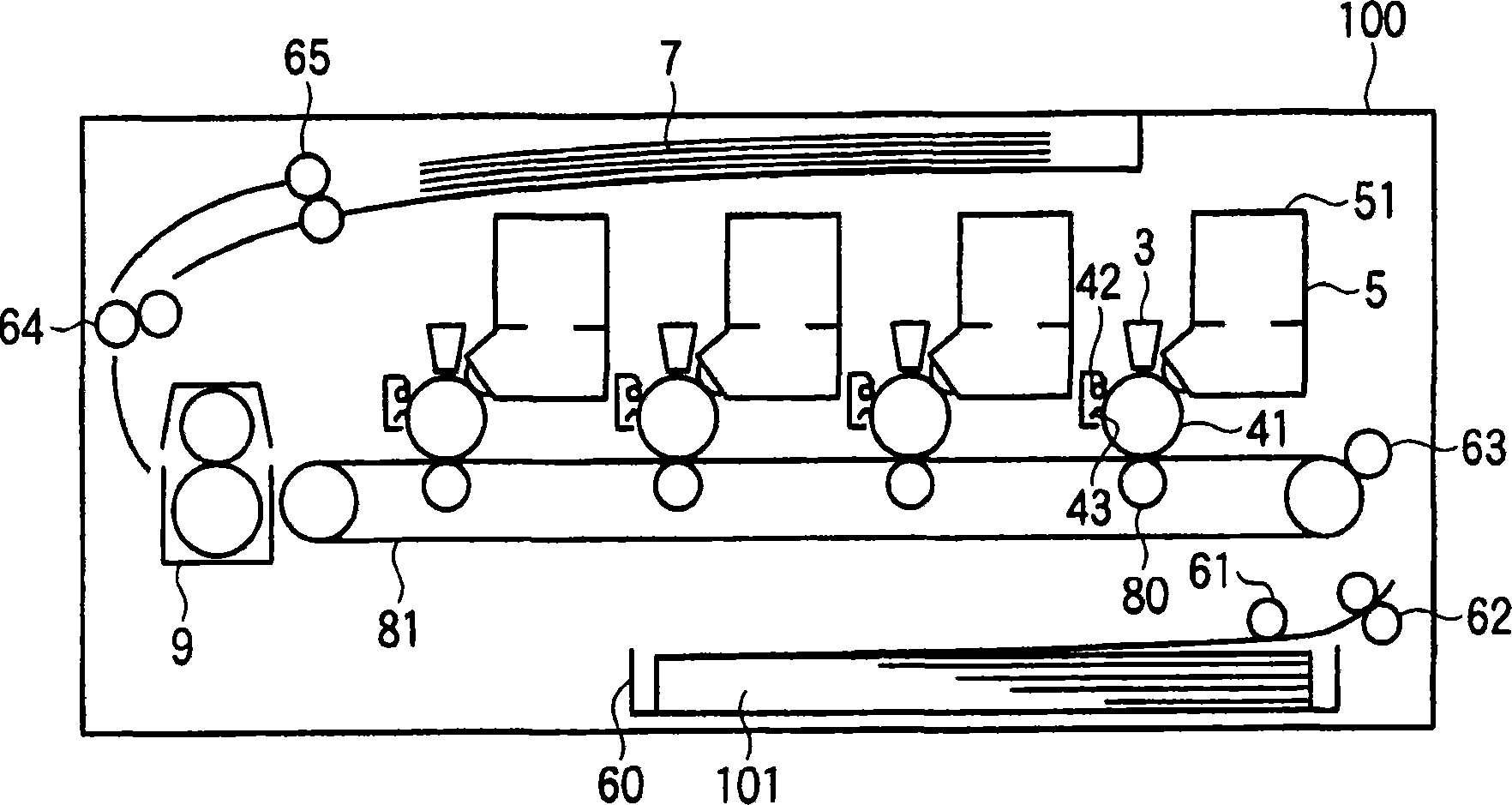

[0029] figure 1 The general configuration of the printer of the first embodiment is illustrated.

[0030] will refer to figure 1 The image forming apparatus or printer 100 of the first embodiment will be described. refer to figure 1 , the printer 100 prints an image on a medium according to image data using a toner formed of a resin containing a pigment therein. A stack of media or paper 101 is accommodated in the paper storage box 60 . Paper feed roller 61 feeds paper 101 from paper storage cassette 60 to conveyance rollers 62 and 63 , which in turn convey paper 101 on a conveyance path.

[0031] The printer 100 is an electrophotographic color printer, and includes print engines for forming yellow images, magenta images, cyan images, and black images, respectively. The print engines are arranged along the transport path of the paper 101 . Each print engine includes a photosensitive drum 41 on which an electrostatic latent image is formed.

[0032] A charging roller 42 ...

no. 2 example

[0104] The lens unit of the first embodiment has been described taking use in an image forming apparatus as an example. The lens unit of the second embodiment will be explained in terms of a lens unit included in an image reading apparatus. Figure 14 The general configuration of the image reading apparatus of the second embodiment is illustrated. Elements similar to those of the first embodiment are given the same reference numerals, and descriptions of these elements are omitted.

[0105] will refer to Figure 14 A second embodiment will be described. refer to Figure 14, the scanner 500 reads an image of a document 507 and generates image data in the form of electronic data. The scanner 500 includes an image reading head 400 , a lamp 501 , a transparent plate 502 , a rail 503 , a drive belt 505 and a motor 506 . A lamp 501 illuminates the surface of a document 507 . The image reading head 400 receives light reflected back from the surface of the document 507, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com