Main beam manufacturing molding bed of shipbuilding gantry crane

A gantry crane and tire mold technology is applied in the field of manufacturing tire molds for the main girder of shipbuilding gantry cranes, which can solve the problems of difficult control of manufacturing precision, long manufacturing cycle, deformation of the main girder box, etc. The effect of avoiding welding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0015] Due to the development of shipbuilding technology, the hull segments are getting bigger and bigger, the span and lifting capacity of shipbuilding gantry cranes are getting bigger and bigger, and the cross-sectional size and weight of the main girder of the crane are also getting bigger and bigger. The traditional technology can no longer meet the requirements of making the main girder of the shipbuilding gantry crane.

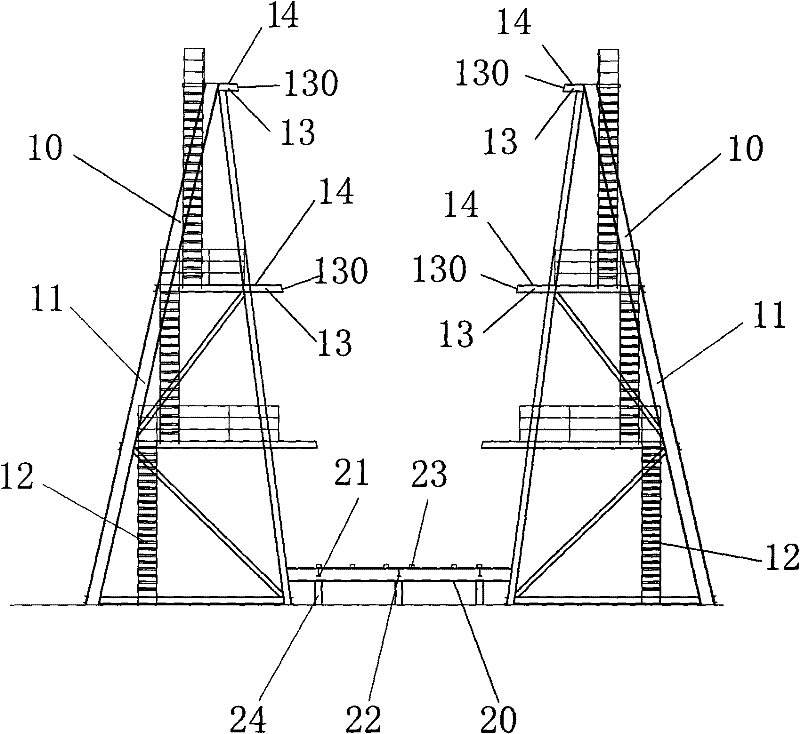

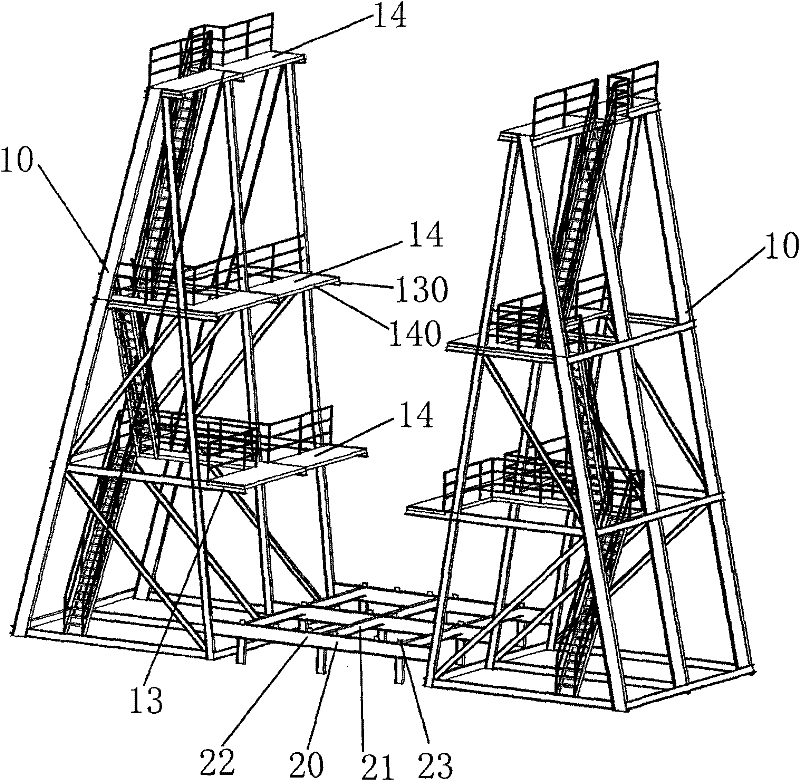

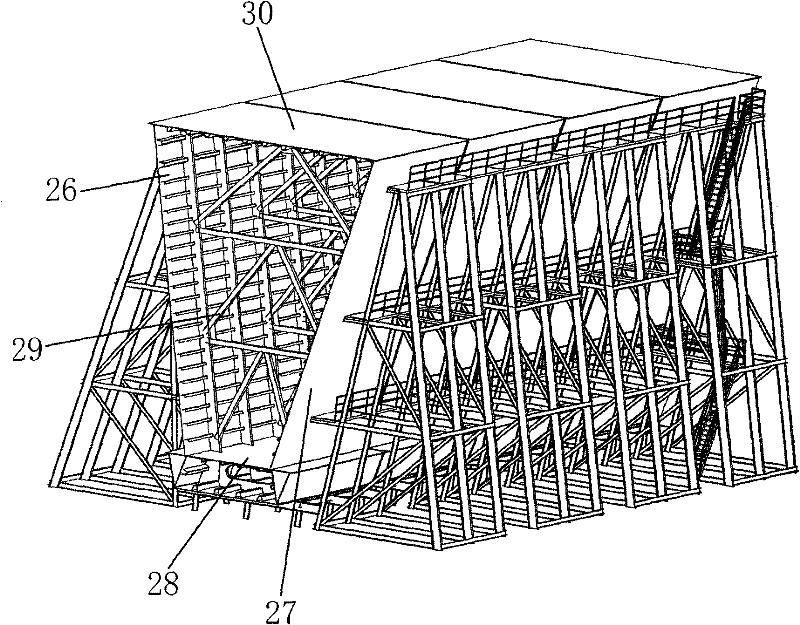

[0016] In order to solve the problems caused by the traditional process of manufacturing the main girder, a tire mold suitable for the manufacture of the main girder of the large-scale shipbuilding gantry crane is given in this embodiment, such as figure 1 , figure 2 As shown in , the tire mold for the main girder of the shipbuilding gantry crane includes two identical and opposite side tire molds 10, and the side tire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com