A steam turbine diaphragm assembly process

An assembly process and steam turbine technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of unstable molding quality, numerous assembly processes, and low manufacturing efficiency, so as to improve the assembly molding quality and reduce the difficulty of assembly technology , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

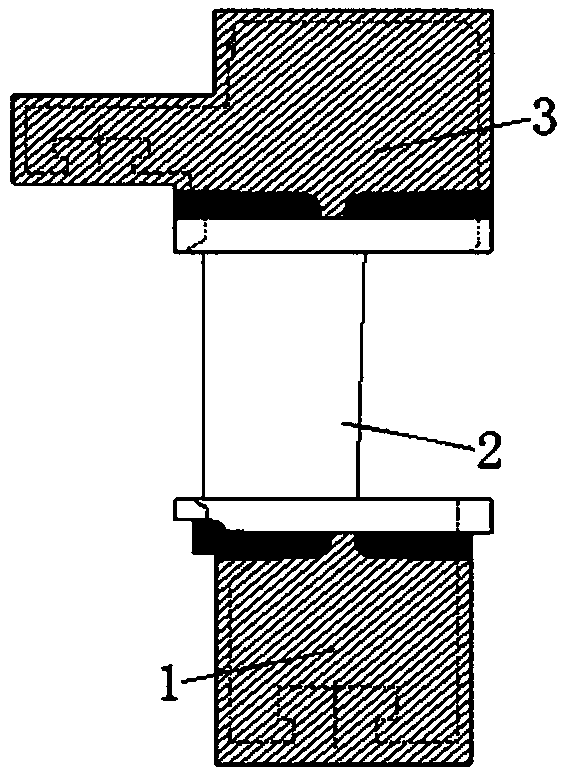

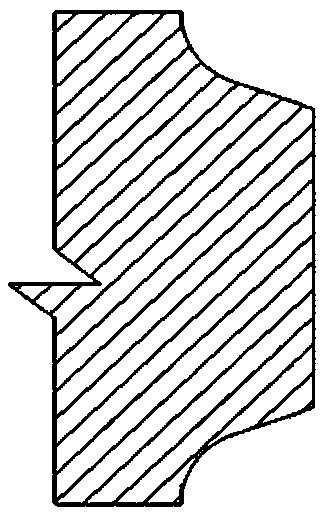

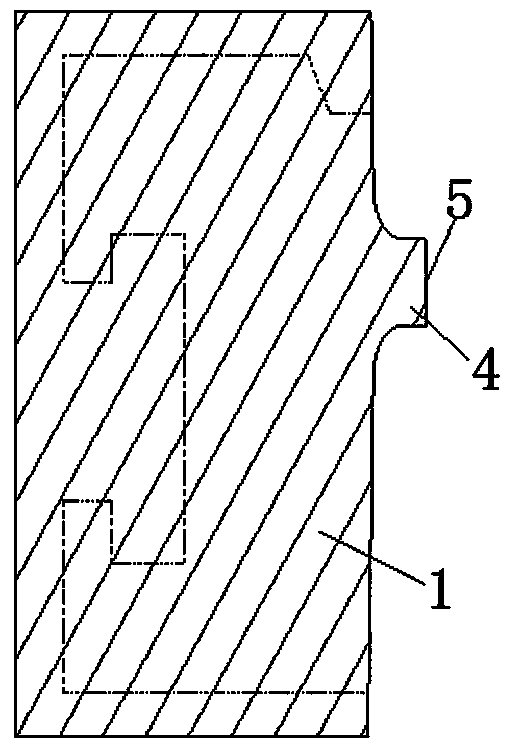

[0024] The present invention relates to an assembly process of a steam turbine baffle, wherein the steam turbine baffle is mainly composed of a baffle body, a plurality of guide blades and a baffle outer ring, and the outer periphery of the baffle body has a raised positioning notch (see image 3 As shown, 1 is the partition body, 4 is the positioning spigot, and 5 is the datum plane), each guide vane is mainly composed of an inner edge plate, a blade body and an outer edge plate; the assembly process includes the following technical measures:

[0025] - Process the assembly surface of the edge plate of each guide vane to be smooth, without welding groove structure;

[0026] -Fit the inner edge plates of each guide vane on the outer periphery of the partition body in turn, specifically, take the top surface of the positioning notch raised on the periphery of the partition body as a reference—that is, the reference plane for brushing, and place the inner edge of each guide vane ...

Embodiment 2

[0030] The present invention relates to an assembly process of a steam turbine baffle, wherein the steam turbine baffle is mainly composed of a baffle body, a plurality of guide blades and a baffle outer ring, and the outer periphery of the baffle body has a raised positioning notch (see image 3 As shown, 1 is the partition body, 4 is the positioning spigot, and 5 is the datum plane), each guide vane is mainly composed of an inner edge plate, a blade body and an outer edge plate; the assembly process includes the following technical measures:

[0031] - Process the assembly surface of the edge plate of each guide vane to be smooth, without welding groove structure;

[0032] -Fit the inner edge plates of each guide vane on the outer periphery of the partition body in turn, specifically, take the top surface of the positioning notch raised on the periphery of the partition body as a reference—that is, the reference plane for brushing, and place the inner edge of each guide vane ...

Embodiment 3

[0036] The present invention relates to an assembly process of a steam turbine baffle, wherein the steam turbine baffle is mainly composed of a baffle body, a plurality of guide blades and a baffle outer ring, and the outer periphery of the baffle body has a raised positioning notch (see image 3 As shown, 1 is the partition body, 4 is the positioning spigot, and 5 is the datum plane), each guide vane is mainly composed of an inner edge plate, a blade body and an outer edge plate; the assembly process includes the following technical measures:

[0037] - Process the assembly surface of the edge plate of each guide vane to be smooth, without welding groove structure;

[0038] -Fit the inner edge plates of each guide vane on the outer periphery of the partition body in turn, specifically, take the top surface of the positioning notch raised on the periphery of the partition body as a reference—that is, the reference plane for brushing, and place the inner edge of each guide vane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com