A sliding floating caliper braking mechanism

A technology of brake mechanism and floating caliper, which is applied in the direction of brake actuators, brake types, brake components, etc., can solve problems such as insufficient supply pressure, potential safety hazards of gas storage tanks, and brake failure, so as to avoid the decline of braking force , Avoid potential safety hazards and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

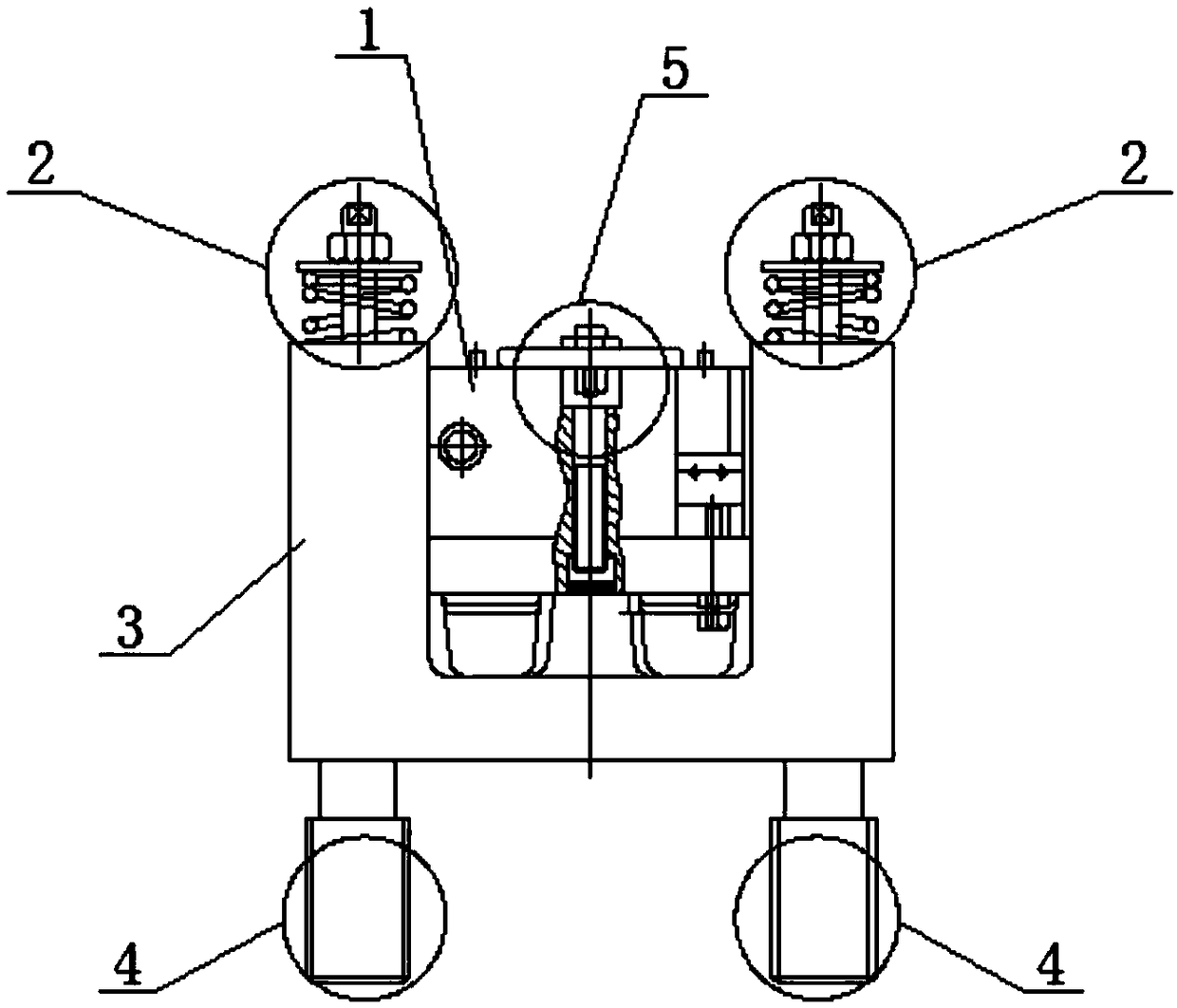

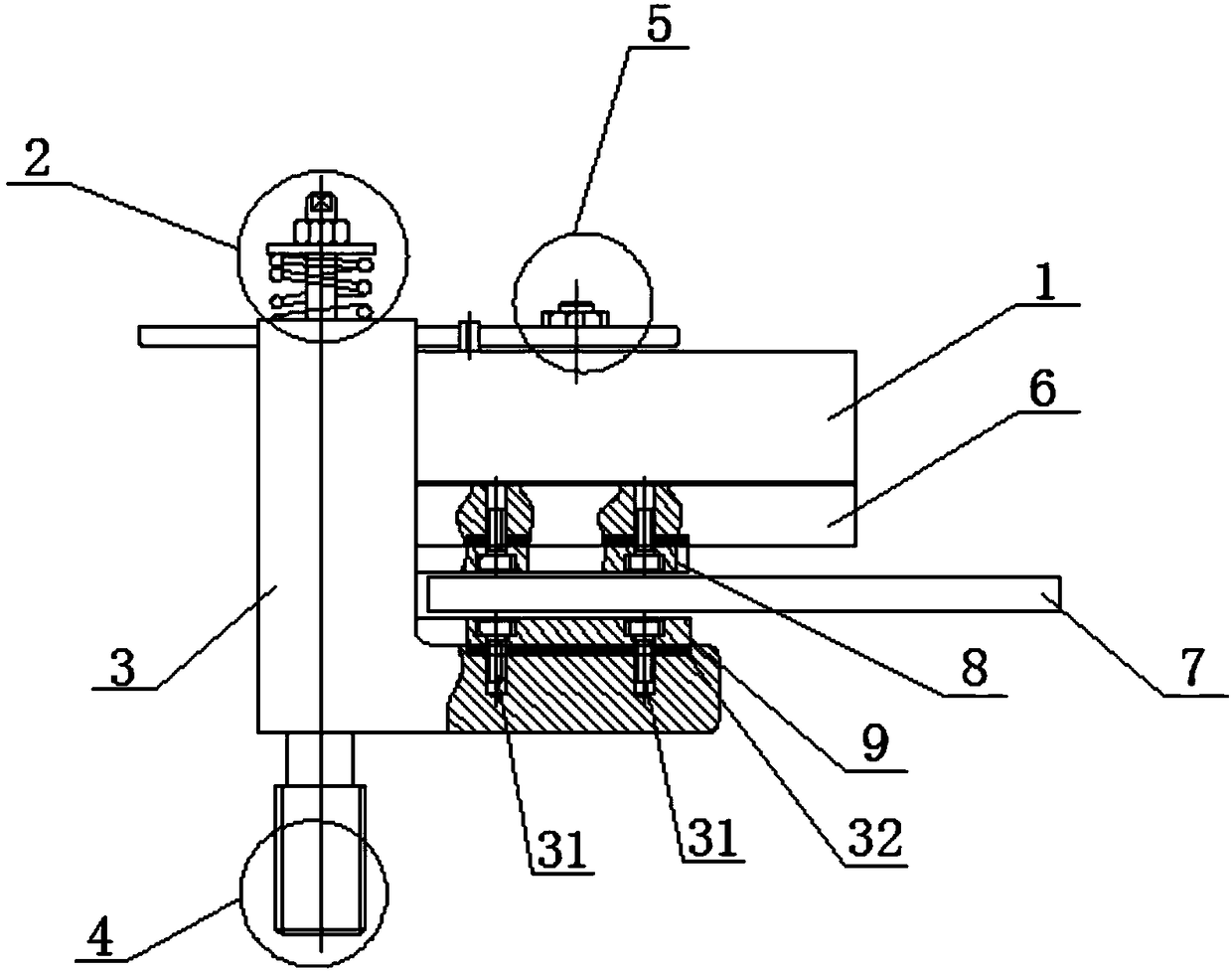

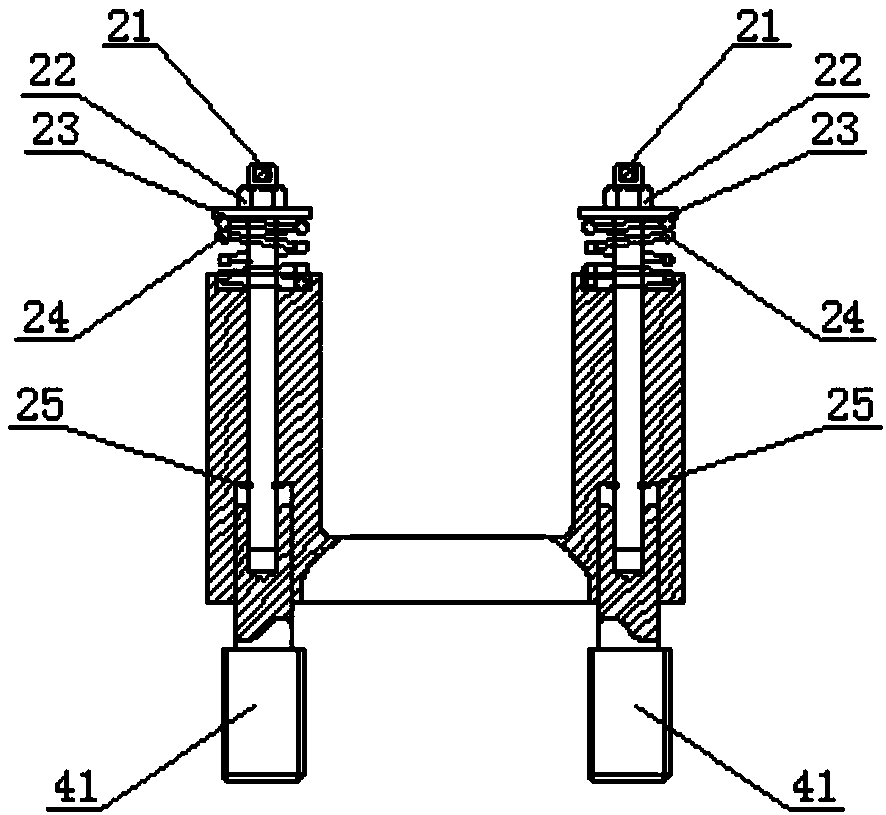

[0028] The invention discloses a sliding floating caliper braking mechanism, such as figure 1 As shown: the main body is a caliper bracket 3, the caliper bracket 3 is L-shaped as a whole, and the caliper bracket 3 includes a brake caliper body 1, a brake disc 7, a spring limiting device 2 and an independent adjustment device for friction plates 5. The four are all arranged in the L-shaped caliper bracket 3; the side of the L-shaped caliper bracket 3 perpendicular to the ground is provided with a recessed area, forming two raised areas; the brake caliper body 1, the brake disc 7 There is an up-down relationship and the two do not touch when they are still, such as figure 2 As shown: the fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com