A kind of self-release glaze ceramic and preparation method thereof

A self-releasing glaze and ceramic technology, applied in the production of ceramic materials, clay products, other household appliances, etc., can solve the problems of narrow firing temperature range and easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

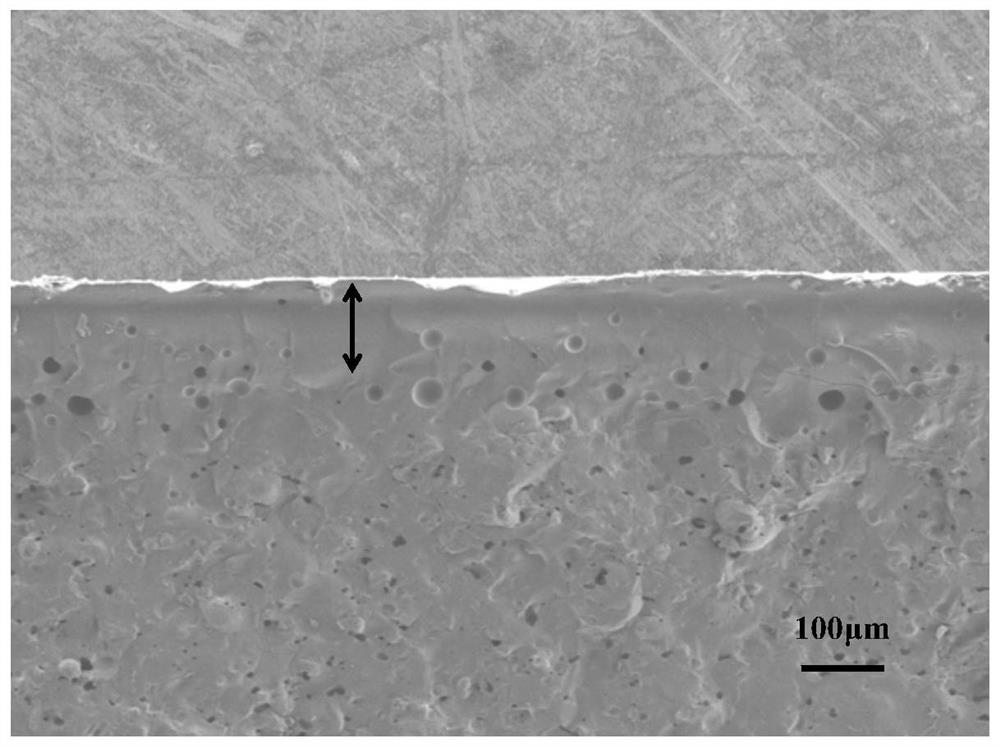

Embodiment 1

[0047]This embodiment provides a self-releasing glaze ceramic, the raw materials of which include 9.38kg base material, 0.45kg glaze layer accelerator and 0.17kg sodium hydroxide;

[0048] Green body base materials include 1.8kg Guangdong washed mud, 2.1kg Yunnan kaolin, 0.6kg porcelain stone, 0.8kg limestone, 0.5kg black talc, 0.12kg refined white bentonite, 2.58kg quartz, 1.3kg orthoclase, 0.12kg alumina micropowder , 0.08kg zirconia micropowder; among them, the fineness of alumina micropowder and zirconia micropowder are both 0.5-6μm, D90≤6μm;

[0049] The glaze layer accelerator is 0.24kg calcium borosilicate frit and 0.21kg lithium china stone, the fineness is 0.5-3μm, D90≤3μm.

[0050] The preparation method of above-mentioned self-release glaze ceramics, comprises the following steps:

[0051] After mixing the raw materials of the green body base material, adding water and mixing to obtain the ingredients, the mass fraction of the ingredients is 70%, and after 16h ball...

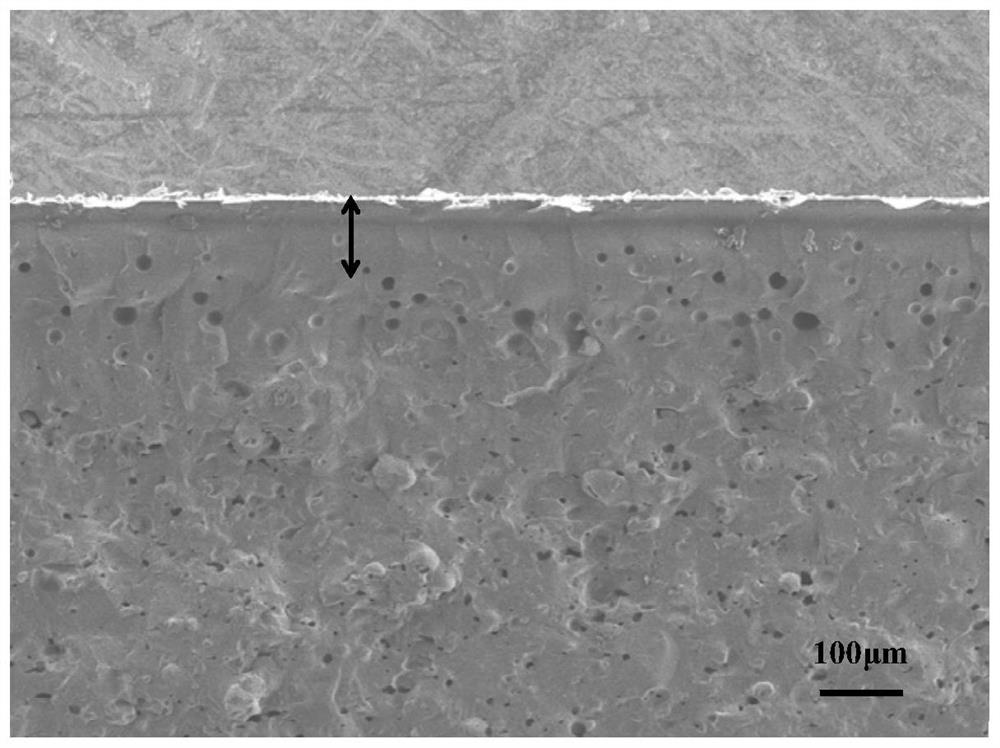

Embodiment 2

[0053] This embodiment provides a self-releasing glaze ceramic, the raw materials of which include 9.45kg of base material, 0.48kg of glaze layer accelerator, 0.04kg of potassium hydroxide and 0.03kg of boric acid;

[0054] Green body base materials include 1.6kg Guangdong washed mud, 2.2kg Yunnan kaolin, 0.8kg porcelain stone, 0.85kg limestone, 0.4kg black talc, 0.11kg white bentonite, 2.7kg quartz, 1.2kg orthoclase, 0.8kg alumina micropowder , 0.06kg zirconia micropowder; among them, the fineness of alumina micropowder and zirconia micropowder are both 0.5-6μm, D90≤6μm;

[0055] The glaze layer accelerator is 0.28kg calcium borosilicate frit and 0.2kg lithium china stone, the fineness is 0.5-3μm, D90≤3μm.

[0056] The preparation method of above-mentioned self-release glaze ceramics comprises the following steps:

[0057] After mixing the raw materials of the green body base material, adding water and mixing to obtain ingredients, the mass fraction of the ingredients is 60%...

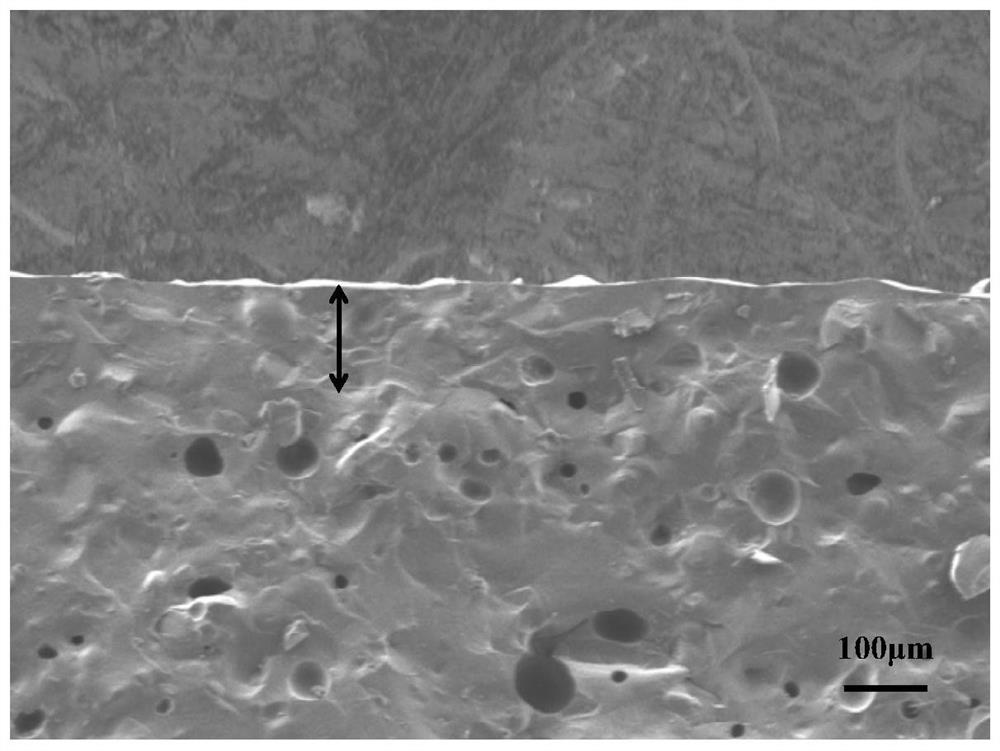

Embodiment 3

[0059] This embodiment provides a self-releasing glaze ceramic, the raw materials of which include 9.6kg of base material, 0.32kg of glaze layer accelerator and 0.08kg of sodium hydroxide;

[0060] Green body base materials include 1.65kg Guangdong washed mud, 2.3kg Yunnan kaolin, 0.65kg porcelain stone, 0.8kg limestone, 0.4kg black talc, 0.15kg refined white bentonite, 2.68kg quartz, 1.1kg orthoclase, 0.15kg alumina micropowder , 0.12kg zirconia micropowder; among them, the fineness of alumina micropowder and zirconia micropowder are both 0.5-6μm, D90≤6μm;

[0061] The glaze layer accelerator is 0.23kg calcium borosilicate frit and 0.09kg lithium china stone, the fineness is 0.5-3μm, D90≤3μm.

[0062] The preparation method of above-mentioned self-release glaze ceramics comprises the following steps:

[0063] After mixing the raw materials of the green body base material, adding water and mixing to obtain the ingredients, the mass fraction of the ingredients is 70%, and afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com