Locking mechanism for tubular vertical rod and tubular vertical rod device employing locking mechanism

A technology of locking mechanism and pole device, applied in the direction of connecting components, mechanical equipment, thin plate connection, etc., can solve the problems of shortening the service life, damage to the tubular pole device, poor effect of the tubular pole, etc., and prolonging the service life. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

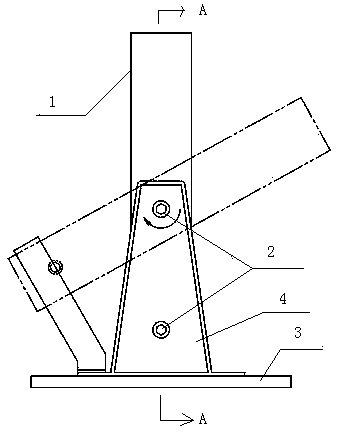

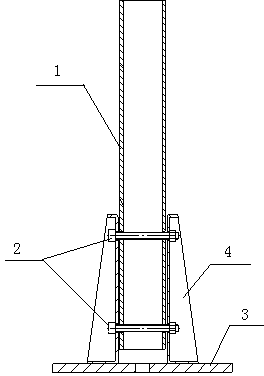

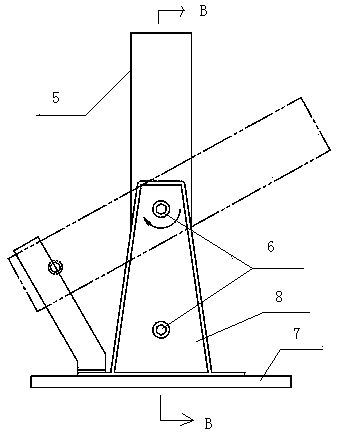

[0023] Embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0024] Examples of locking mechanisms for tubular uprights, such as Figure 3~6 As shown, the locking mechanism includes a pair of screws 6 and a locking combination block corresponding to the screws 6 for clamping the wall of the tubular vertical rod 5. The two locking blocks 9 oppositely arranged in the radial direction and the two elastic members between the two locking blocks 9 that apply a force in the direction away from the two locking blocks 9, each locking block 9 is provided with There is a threaded hole 11 that is screwed and matched with the screw 6, and the locking combination block is realized to be screwed and matched with the screw 6 through the locking block 9, and the positions on both sides of the screwed hole 11 on the opposite surfaces of the two locking blocks 9 are provided with The installation holes for placing the elastic parts, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com