A bottle unscrambling turntable structure and processing method thereof

A processing method and turntable technology, which is applied to metal processing equipment, manufacturing tools, rotary conveyors, etc., can solve the problems of easy deformation and long production cycle, and achieve the effects of saving costs, reducing cleaning time, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

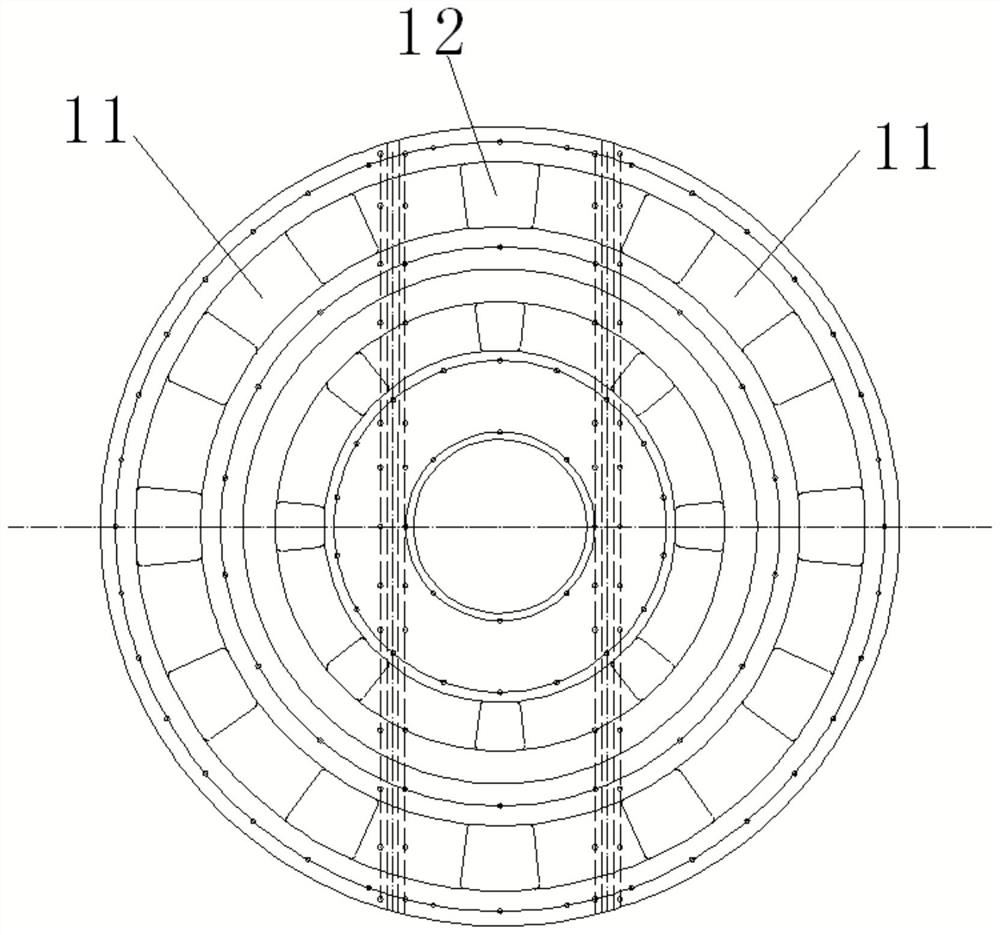

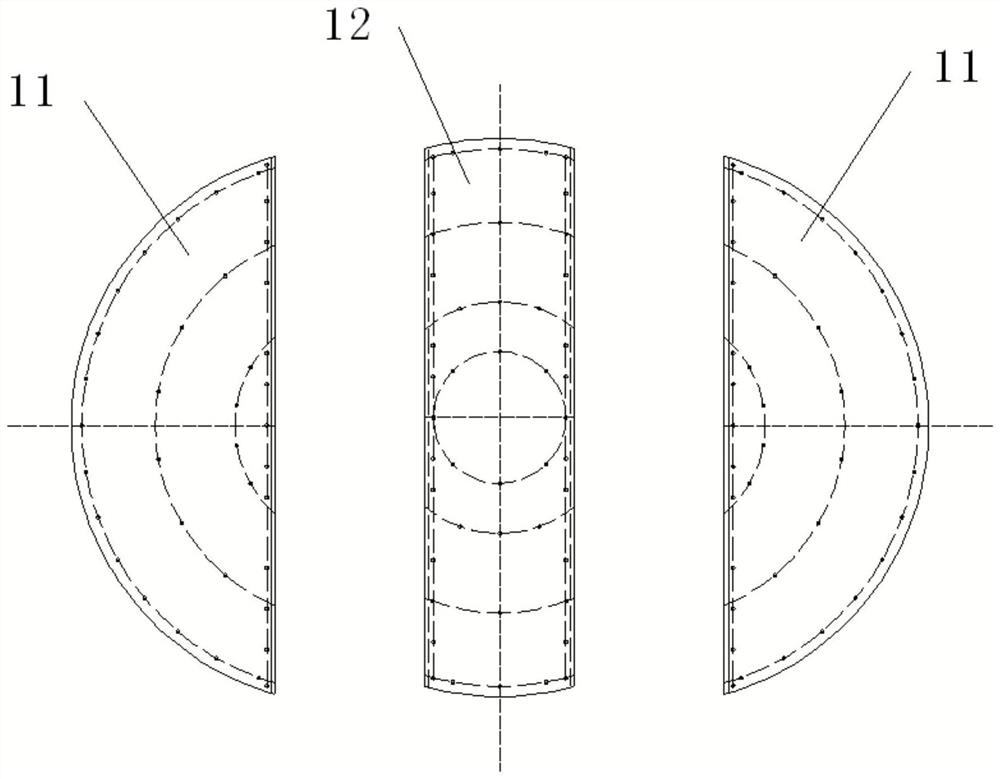

[0033] The bottle unscrambling turntable structure of this embodiment includes a bottle unscrambling turntable 1 and a mounting plate 2. The bottle unscrambling turntable 1 is formed by splicing two arc panels 11 and an intermediate panel 12 arranged between the two arc panels 11. Both the curved panel 11 and each intermediate panel 12 are fixed on the mounting plate 2 . By dividing the larger-diameter bottle unscrambling turntable 1 into three pieces, and then splicing them together, the single arc panel 11 and the middle panel 12 are smaller in size, do not need to be processed by a larger mold, are easy to process, and will not be deformed problem, shorten the production cycle.

[0034] In this embodiment, the seam between the arc panel 11 and the middle panel 12 is a vertical plane. The arc panel 11 and the middle panel 12 are also fixed on the installation plate 2 by the installation screws 3 .

[0035] The processing method of the bottle unscrambling carousel structure...

Embodiment 2

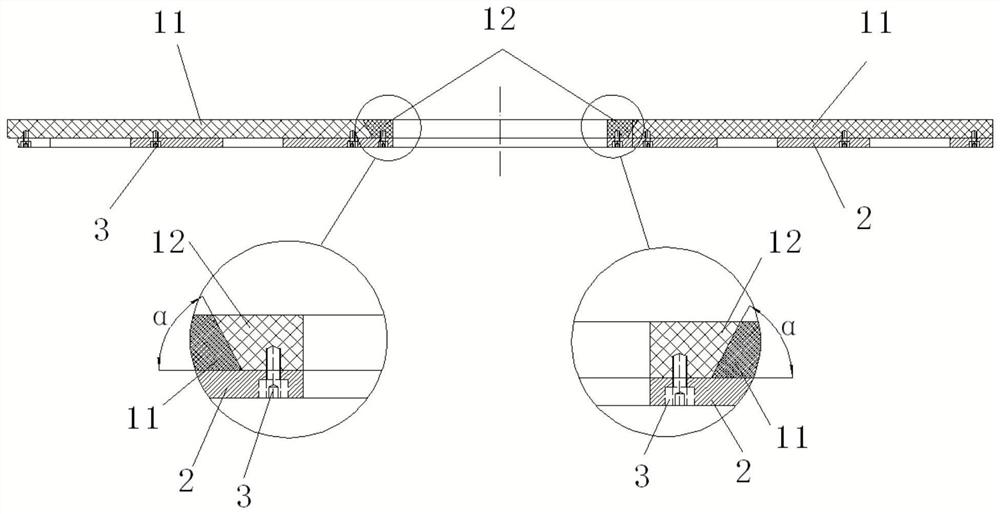

[0039] Such as Figure 1 to Figure 4 Shown, the bottle unscrambling carousel structure of the present embodiment is different from embodiment 1 in that:

[0040] In this embodiment, the bevel joint structure is formed between the arc panel 11 and the adjacent intermediate panel 12 and between two intermediate panels 12, that is, the bevel is formed between each joint, and the bevel in the adjacent two bevel joint structures The included angles with the horizontal plane of the mounting plate 2 are respectively positive α and negative α, and the preferred range of α is 45°-90° (excluding 90°). Through the setting of positive α and negative α, an installation space with an inverted trapezoidal cross section (inverted trapezoid refers to a trapezoid whose upper bottom length is greater than the lower bottom length) is formed between the two arc panels 11, so that the middle panel is finally placed 12 Press into the installation space with an inverted trapezoidal cross section, so...

Embodiment 3

[0047] Such as Figure 5 As shown, the structure of the bottle unscrambling carousel of the present embodiment is basically the same as that of Embodiment 2, the only difference being:

[0048] In this embodiment, there are three middle panels 12 .

[0049] Since the middle panel 12 is set to three, its processing method is slightly different from that of embodiment 2, specifically:

[0050]Number the three middle panels 12, and mark them as A1, A2, and A3 in turn. First, fix the two arc panels 11 on the mounting plate 2, and then fix the even-numbered middle panel 12, that is, A2, on the mounting plate 2, an inverted trapezoidal installation space is formed between one arc panel 11 and A2, and between the other arc panel 11 and A2, and then the odd-numbered middle panels 12, that is, A1 and A3, are pressed into each The installation space forms an interference fit and is fixed with the installation disk 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com