A Welding Manufacturing Process of Aluminum Alloy Cross Beam Composition of EMU

A technology of aluminum alloy beam and manufacturing process, which is applied in the field of welding and manufacturing process of aluminum alloy beams of EMUs, can solve the problems of inability to weld and form, the back space of the welding seam is narrow, and the welding gap cannot be adjusted, etc., so as to ensure the assembly size and welding Seam requirements, prevent the collapse of the welding surface, easy to control and achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

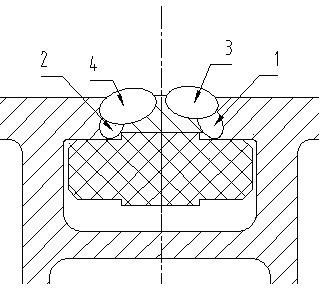

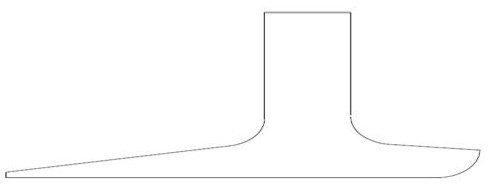

[0021] See attached figure 1 with 2 Shown, the present invention prepares the step of described EMU horizontal composition to be six steps. The first step is to prepare before welding, check the on-site temperature, humidity, shielding gas, welding wire, and whether the performance of the welding machine is good. When the on-site temperature and humidity meet the requirements, conduct the pre-weld welding process test, use an 8mm aluminum plate to weld a weld seam with a length of more than 200mm, and then conduct the welding process test by the welding supervisor; the second step is cleaning and polishing, and the parts are cleaned with a cleaning agent. 1-2 Clean the oil stain within 30mm of the welding area, and then use a mechanical polishing machine to throw away the oxide film at the 20mm of the welding seam; the third step is to assemble the spot welding, and put it in the assembly rib according to the requirements of the drawing Removable welding backing plate, use t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com