Method for improving performance of lead-free ferroelectric film and lead-free ferroelectric film prepared by same

A ferroelectric thin film, lead-free ferroelectric technology, applied in the field of lead-free ferroelectric thin film, can solve the problems of insignificant effect, influence of thin film performance, difficult control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

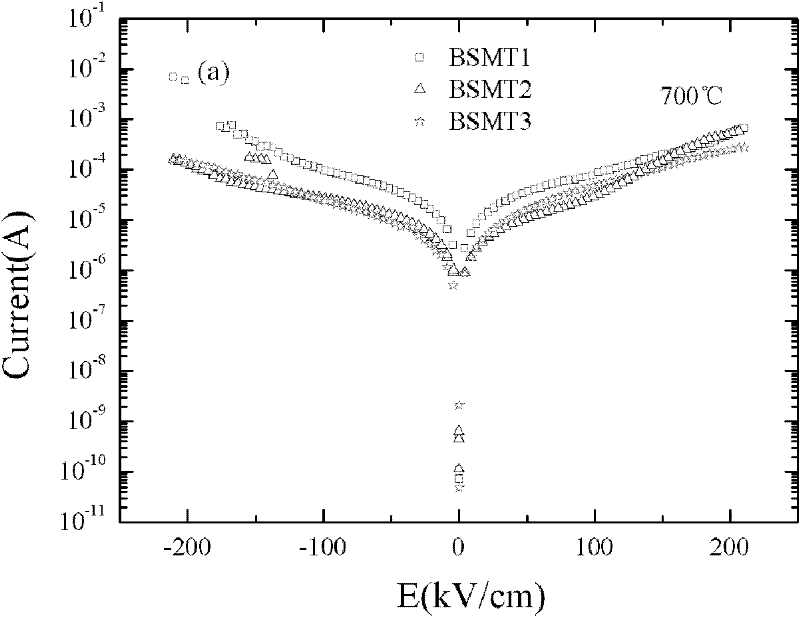

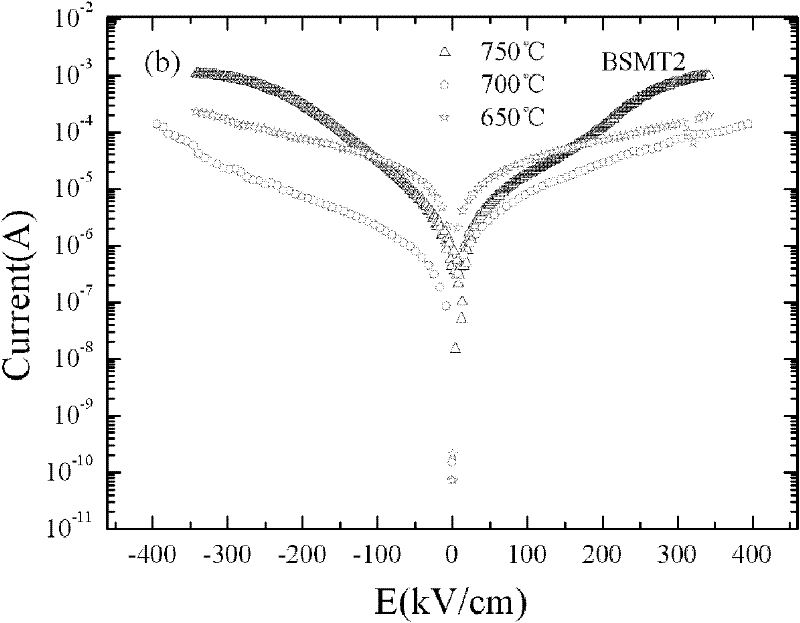

Image

Examples

Embodiment 1

[0028] (1), with electronic balance, according to the mol ratio of Bi and Nd be 3.15: 0.85 to take by weighing bismuth nitrate (excessive 4%) 1.6051g and neodymium acetate 0.2734g respectively, then add glacial acetic acid solvent, magnetically stir at normal temperature to complete dissolved to form a mixed solution of bismuth nitrate and neodymium acetate. According to the molar ratio of Bi, Nd and Ti being 3.15:0.85:3, weigh 1.0313 g of butyl titanate, slowly add it to the above mixed solution, then add glacial acetic acid and ethylene glycol methyl ether solvent (the molar ratio of which is 1 : 1), continue to stir for 2h to obtain 20ml of 0.05mol / L precursor solution, after standing for 7 days, filter to obtain clear and transparent lavender Bi 3.15 Nd 0.85 Ti 3 o 12 Precursor solution.

[0029] Coating the precursor solution on Pt / Ti / SiO 2 On the / Si substrate, adopt the spin coating process, use the homogenizer, first spin the glue at a low speed, the speed is 500r...

Embodiment 2

[0032] (1) To prepare a lead-free ferroelectric thin film, the steps are the same as in Example 1.

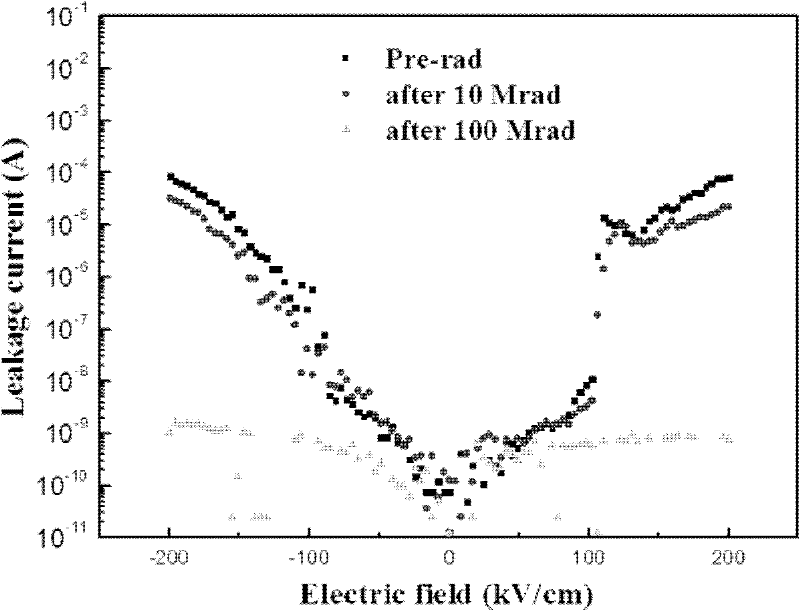

[0033] (2), using the gamma rays produced by the decay of cobalt 60 as the irradiation source, the energy of the rays is 1.33MeV, and at room temperature, the prepared neodymium-doped bismuth titanate lead-free ferroelectric thin film is irradiated, and the total irradiation dose It is 40 Mrad. After irradiation, a ferroelectric thin film with reduced leakage current is obtained.

Embodiment 3

[0035] (1) To prepare a lead-free ferroelectric thin film, the steps are the same as in Example 1.

[0036] (2), using the gamma rays produced by the decay of cobalt 60 as the irradiation source, the energy of the rays is 1.33MeV, and at room temperature, the prepared neodymium-doped bismuth titanate lead-free ferroelectric thin film is irradiated, and the total irradiation dose It is 70 Mrad. After irradiation, a ferroelectric thin film with reduced leakage current is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com