Automatic lug shaping mold

An ear mold and automatic technology, which is applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of easily damaged ears, low efficiency, and large labor consumption, etc., to achieve fast sorting, good sorting effect, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

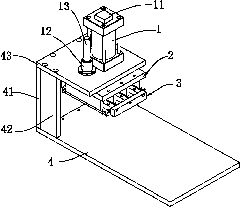

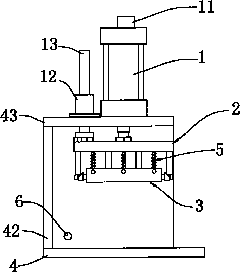

[0021] like figure 2 , image 3 As shown, the present invention is an automatic ear mould, comprising a mold base, a shaping mechanism 3 and a push plate mechanism 2 arranged above the shaping mechanism 3, the shaping mechanism 3 and the pushing plate mechanism 2 are connected by an elastic mechanism 5, and the shaping A shaping groove 36 that can move laterally is arranged in the mechanism 3, and the pushing plate mechanism 2 pushes the shaping mechanism 3 to move through the elastic mechanism 5 so that the product lug enters the shaping groove 36, and the pushing plate mechanism 2 acts on the shaping mechanism 3 when it goes down. The shaping groove 36 shrinks laterally to realize tab arrangement.

[0022] like Figure 4 to Figure 7 As shown, the preferred structure is as follows: the shaping mechanism 3 is a fence-like structure formed by a plurality of shaping units connected in series through fixing strips 31 and pin shafts 32. The movable clip 34, the shaping groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com