Sugarcane root removing machine

A root and sugarcane technology, applied in the field of sugarcane root removal machine, can solve the problems of smooth cutting, difficult sugarcane head end, difficulty in ensuring the safety of manual operation, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

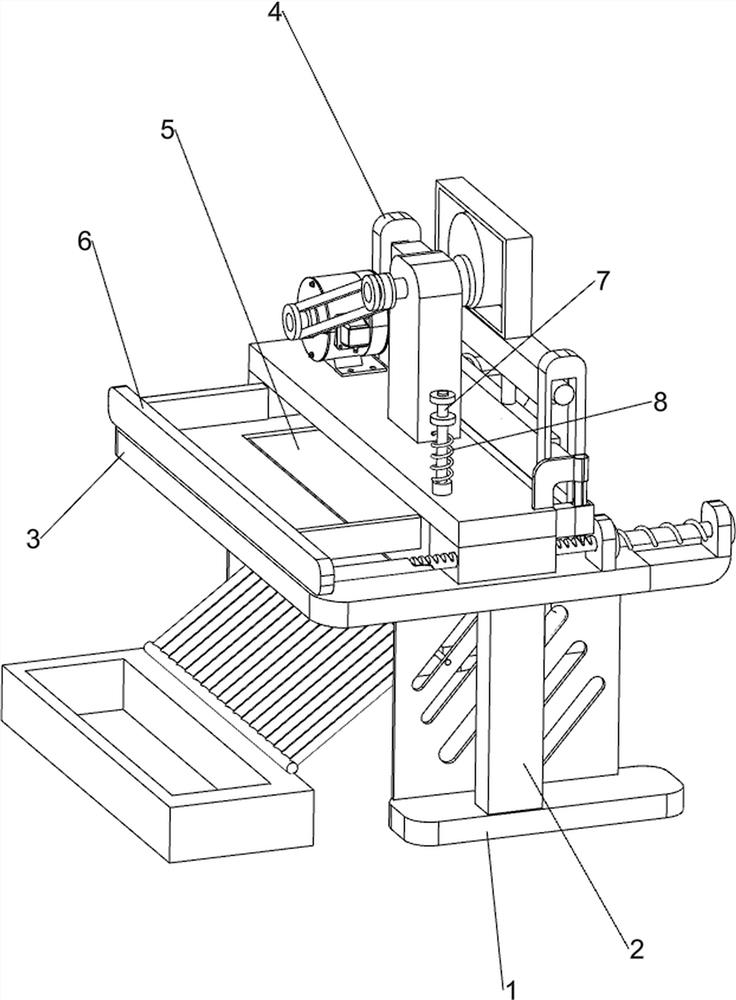

[0025] A sugarcane root removal machine such as Figure 1-5 As shown, it includes a base 1, a pillar 2, a workbench 3, a transmission mechanism 4 and a blanking mechanism 5, the top of the base 1 is connected with a pillar 2, the top of the pillar 2 is connected with a workbench 3, and the workbench 3 is equipped with a transmission mechanism 4 , A blanking mechanism 5 is connected between the base 1 and the workbench 3 .

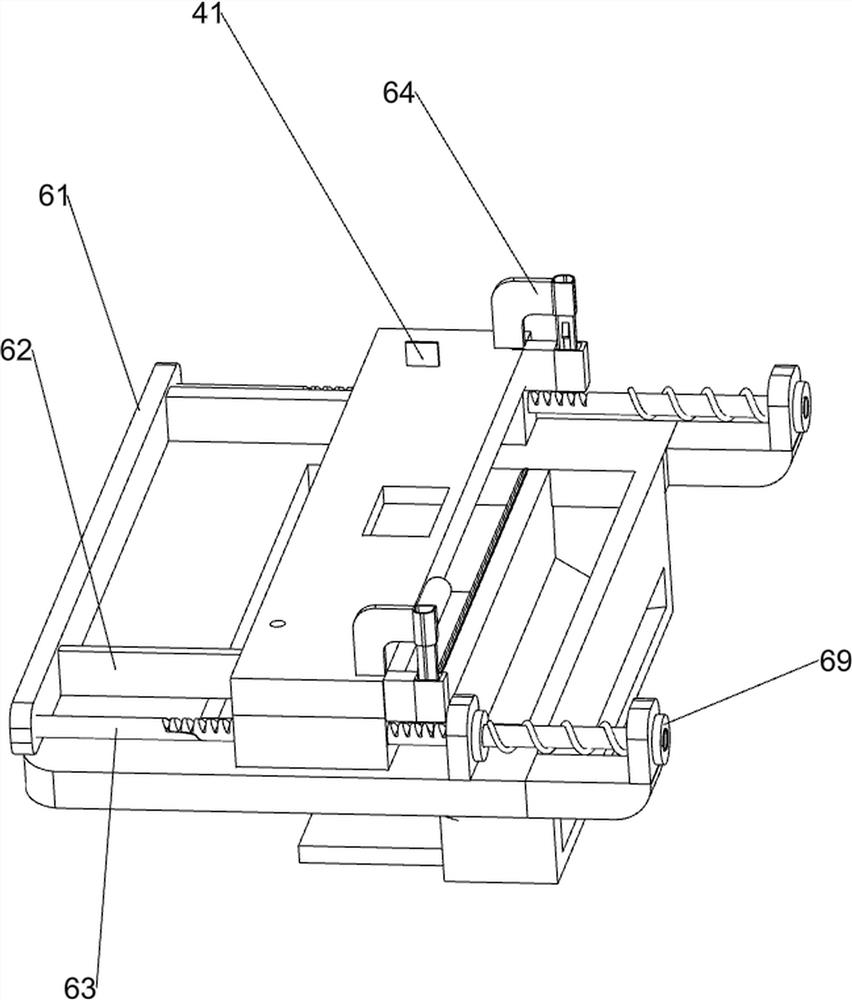

[0026] Transmission mechanism 4 comprises motor supporting platform 41, reduction motor 42, first pulley 43, flat belt 44, second pulley 45, power transmission shaft 46, rotating block 47, pressing block 48, first connecting rod 49 and blade 410, work A motor support platform 41 is installed on the left side of the top of the table 3, and a reduction motor 42 is installed on the rear side of the motor support platform 41. The first pulley 43 is installed on the output shaft of the reduction motor 42, and the transmission shaft is installed in the middle of ...

Embodiment 2

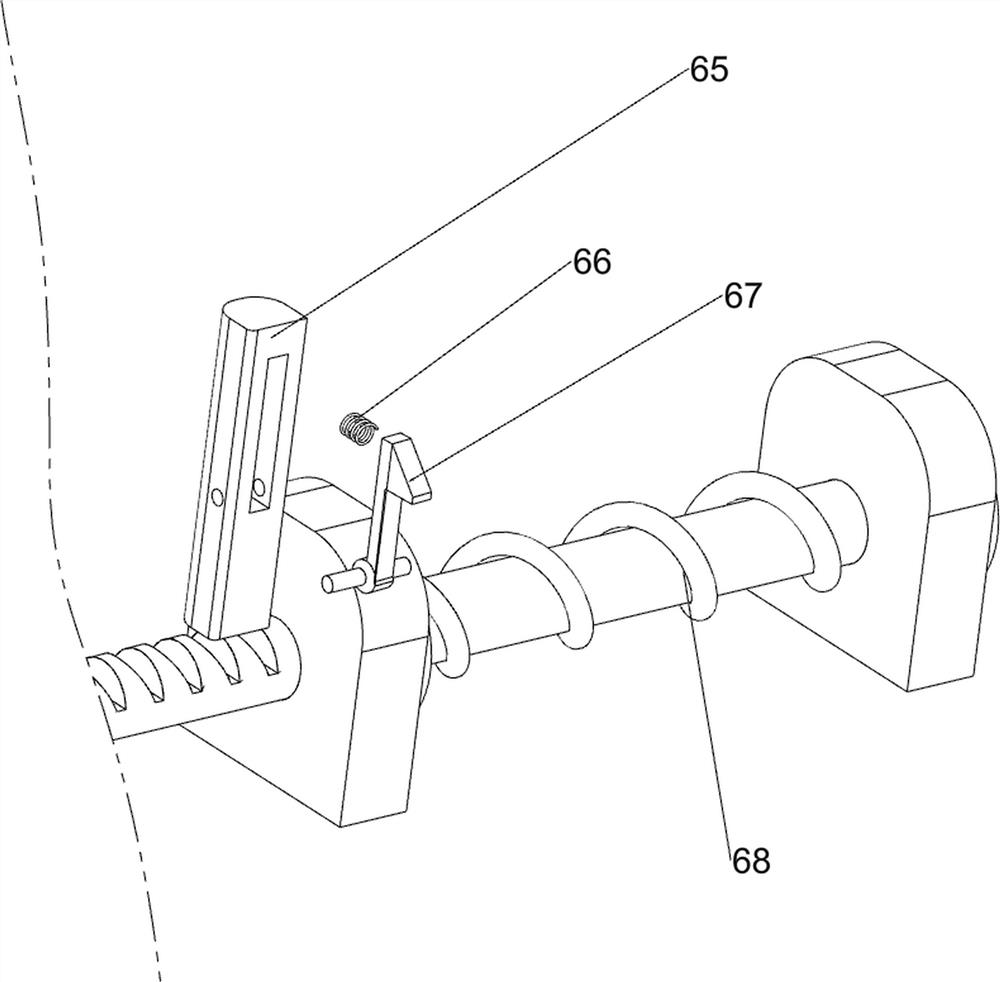

[0030] On the basis of Example 1, such as Figure 6 and Figure 7 Shown, also comprise pushing material mechanism 6, and pushing material mechanism 6 comprises push rod 61, the second baffle plate 62, adjusting rod 63, fixed block 64, sliding block 65, first compression spring 66, wedge-shaped block 67, The second compression spring 68 and the spring fixing bolt 69 are all slidingly connected with adjusting rods 63 at the front and rear sides of the motor support table 41, and the right ends of the two adjusting rods 63 are all slidably connected with the workbench 3, and the tops of the adjusting rods 63 are evenly spaced There is a one-way card slot on the ground, a push rod 61 is connected between the left ends of the two adjustment rods 63, and two second material retaining plates 62 are connected to the right side of the push rod 61, and the two second material retaining plates 62 are located on the two sides. Between the root adjustment rods 63, two fixed blocks 64 are ...

Embodiment 3

[0033] On the basis of Example 2, such as figure 1 As shown, it also includes a lower pressing rod 7 and a support spring 8, the top front side of the motor support table 41 is slidably connected with the lower pressing rod 7, the lower pressing rod 7 is sleeved with a supporting spring 8, and the supporting spring 8 is connected to the Between the motor support platform 41 and the lower pressing rod 7.

[0034] When the sugarcane on the lower feed plate 51 needs to be collected, the lower pressing rod 7 is pushed downwards, the support spring 8 is compressed, and the lower pressing rod 7 promotes the lower feeding board 51 to move downward, so that it is more convenient when the lower feeding board 51 is opened. Further improve work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com