Paper collection unit device for digital ink jet printer

A digital inkjet technology for printing machines, applied in stacking receiving devices, transportation and packaging, sending objects, etc., can solve the problems of increasing the labor intensity of the staff and reducing efficiency, so as to reduce the disorder of order placement and reduce labor intensity , Reduce the effect of paper jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

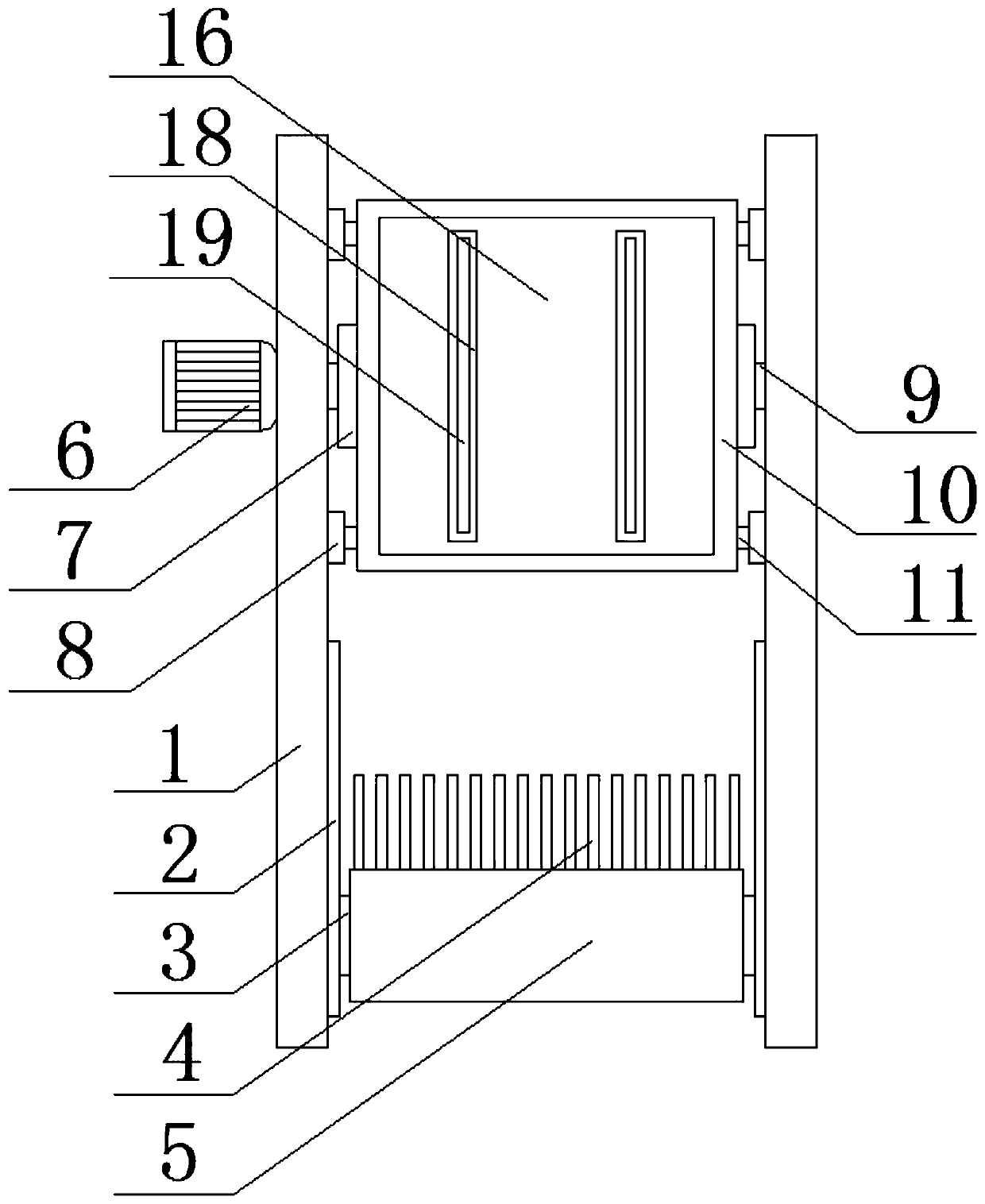

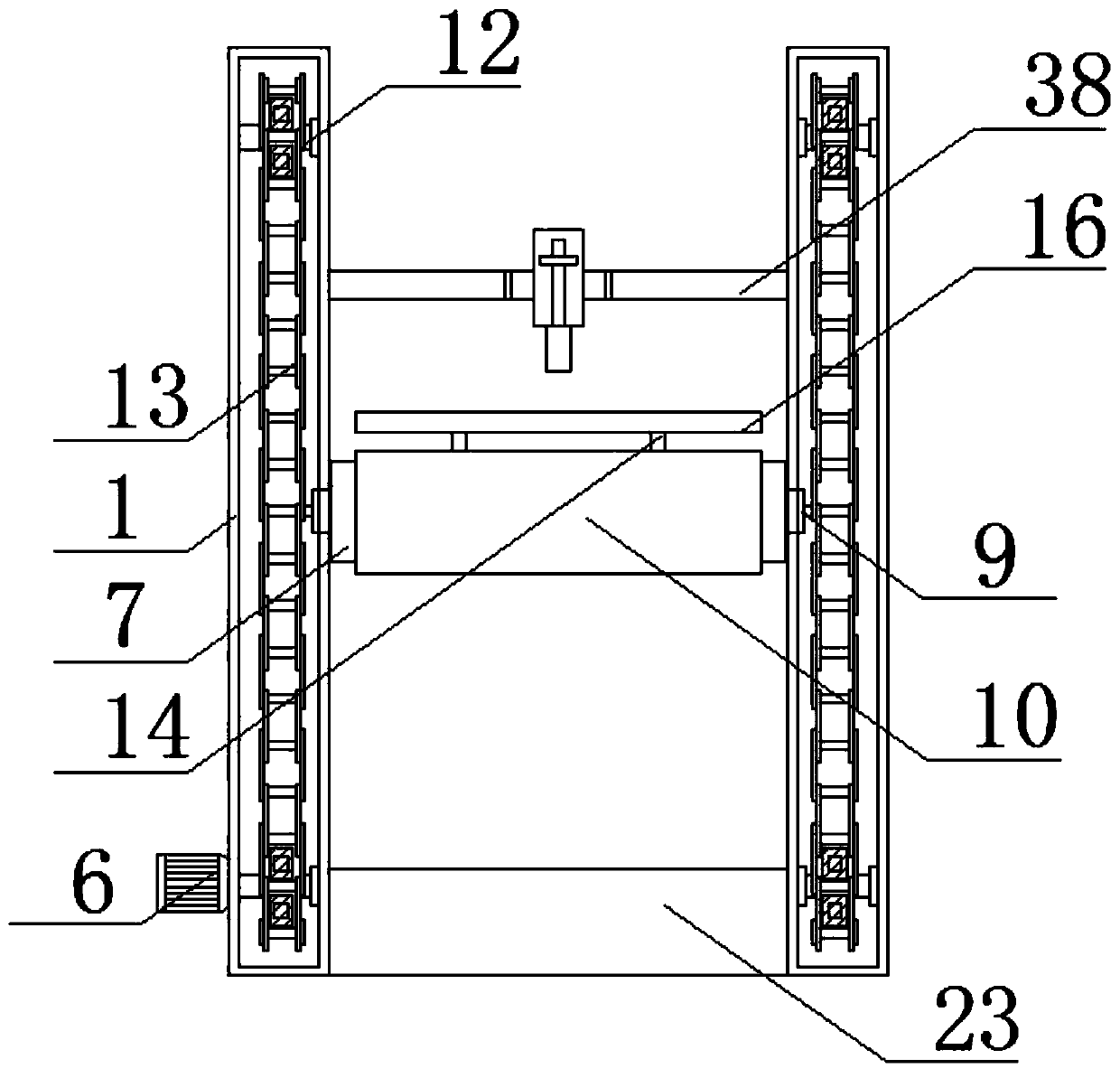

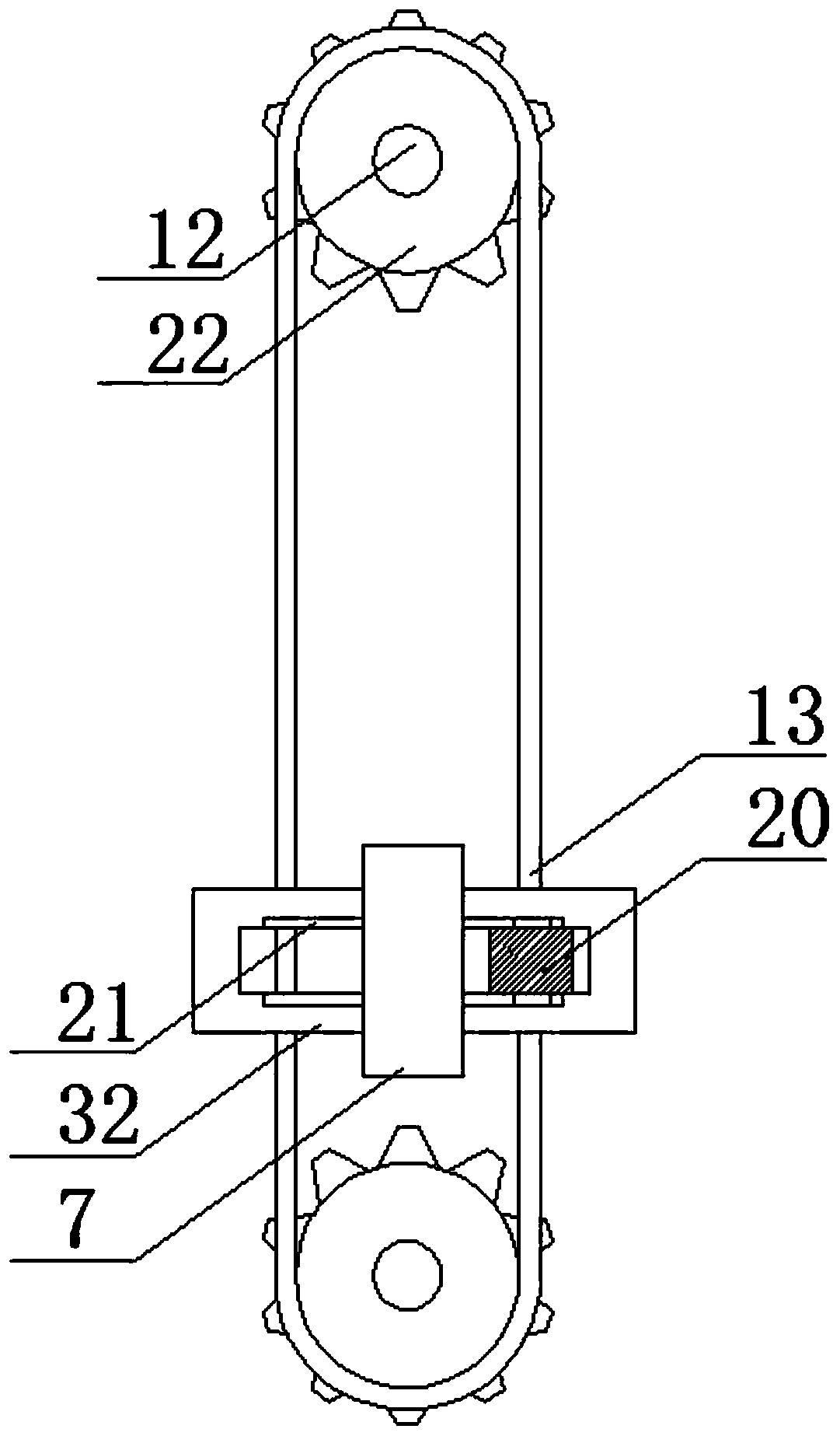

[0029] refer to Figure 1-8 , a paper delivery unit device for a digital inkjet printing machine, comprising two fixed plates 1, both fixed plates 1 are provided with placement cavities, both placement cavities are provided with lifting devices, and the two lifting devices are equipped with The first connecting plate 7 is fixed, and the bearing plate 10 is fixed between the two first connecting plates 7. The first connecting plate 7 controls the lifting of the bearing plate 10. As the number of papers increases, slowly adjust the bearing plate 10. position, two first slide rails 8 are fixed on opposite sides of the two fixed plates 1, second slide blocks 11 are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com