Positioning method and structure of cooker lid

A technology of positioning structure and positioning method, applied in pressure cookers and other directions, can solve the problems of easy aging and jamming, dirt breeding bacteria and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

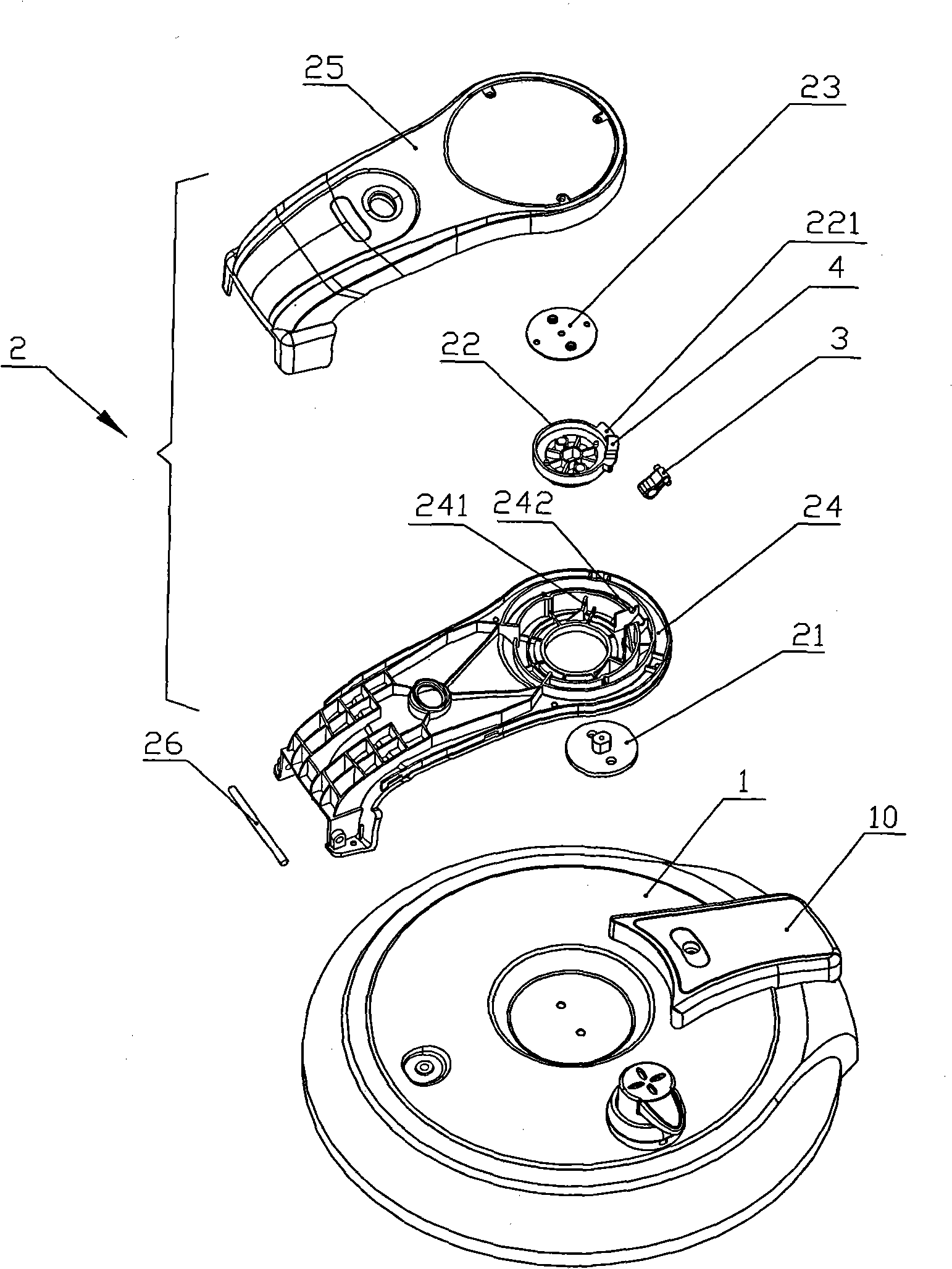

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the positioning structure of the pot cover includes a pot cover 1, a pot cover support arm 2 and a pendulum 3.

[0035] Described pot cover support arm 2 is rotatably fixed on the pot body (not shown in the figure) by hinge shaft 26. The pot cover support arm 2 includes an upper support arm 25 and a lower support arm 24, and the upper support arm 25 and the lower support arm 24 are buckled up and down;

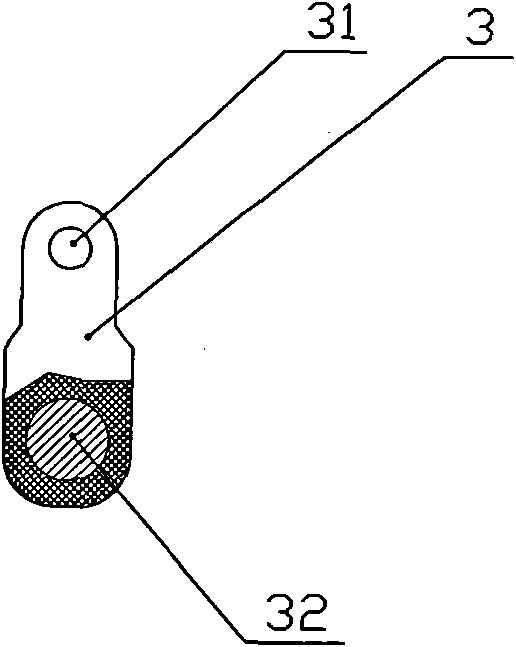

[0036] The pendulum 3 is accommodated in the space between the upper support arm 25 and the lower support arm 24 . The pendulum 3 is made of plastic, and the rotating shafts 31 provided on both sides of the top end are rotatably positioned in the slot 242 on the lower support arm 24 . Wherein the pendulum 3 is gourd-shaped, the cross-section of the top end is smaller than the cross-section of the tail end, and a metal bead 32 is accommodated in the tail end, thereby increasing the swinging...

Embodiment 2

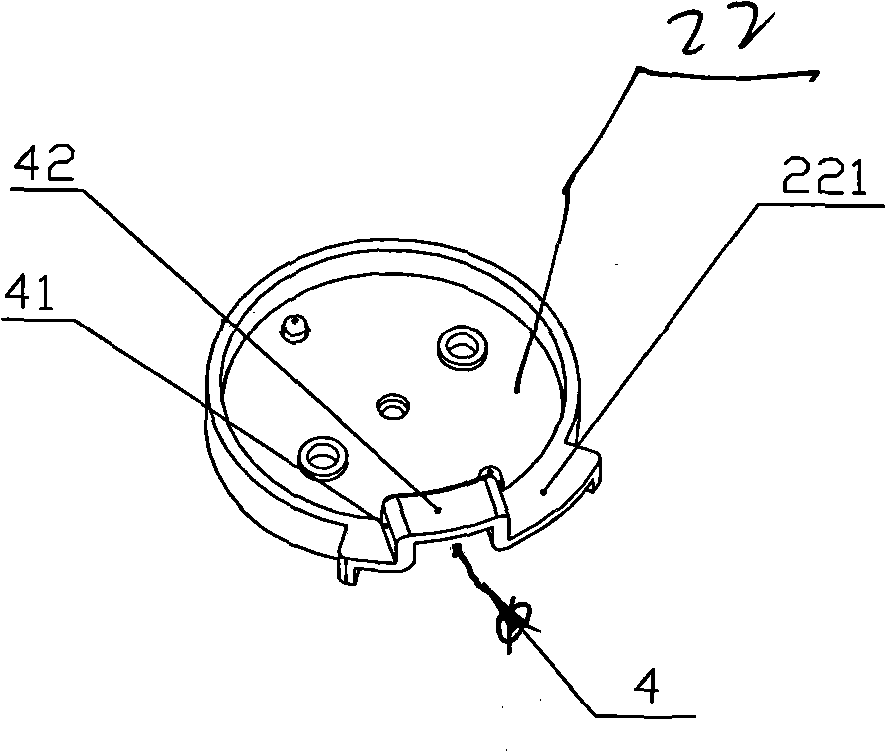

[0044] Such as Figure 6 and Figure 7 As shown, the difference from Embodiment 1 is that the top end of the pendulum 3 is rotatably positioned on the upper surface of the pot cover 1, and the pot cover 1 is connected to the pot cover support arm 2. On the pot body 11; wherein a pit that can accommodate the pendulum 3 is set on the upper surface of the pot cover 1, a slot is set in the pit, and the rotating shaft 31 provided on both sides of the pendulum 3 can It is rotatably positioned in the card slot; as for the rotatable positioning method of the rotating shaft 31 in the card slot, various conventional technical solutions such as auxiliary cover plate and chute structure can be used. Secondly, a positioning groove 4 adapted to the pendulum 3 is provided on the support arm 2 of the pot lid, wherein the notch of the positioning groove 4 faces the pendulum 3 . When the pot cover 1 is in the horizontal position, the pendulum 3 is accommodated in the groove on the top of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap